A New Era of Technical Leadership

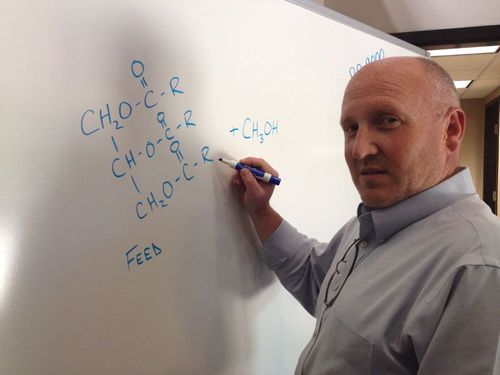

Scott Fenwick became the National Biodiesel Board’s new technical director last year, taking over the role from Steve Howell who continues to serve the organization as senior technical advisor. / PHOTO: NATIONAL BIODIESEL BOARD

September 9, 2014

BY Ron Kotrba

The best way to understand an issue is to see it from all sides, to know what adversaries want in a resolution. The relationship between the petroleum and biodiesel industries is a complicated one—competition and partnerships, opposition and patronage, all rolled into one complex dynamic. Therefore, who better to serve as the biodiesel industry’s technical point-person than someone who began their career in the oil business followed by 25 years’ worth of laboratory experience?

Scott Fenwick became the National Biodiesel Board’s technical director last year, taking over for Steve Howell, who left big shoes to fill. While Howell is still with the organization in a senior technical advisory role, Fenwick has assumed the day-to-day responsibilities Howell managed so well for so long.

Fenwick grew up in central Illinois and went to school at Purdue University studying chemical engineering and chemistry. Shortly after graduating, he moved to New Orleans, closer to his extended family, in order to get a start in the oilfield business. After working part time for some barge operations and oil-site remediation, Fenwick began working for several global, independent lab service companies. This was more than 25 years ago. After a few years, he moved to Houston to help manage a larger laboratory. While working in Houston for several years, and on a trip back to New Orleans, he met his wife. When they married in 1994, he was relocated back to New Orleans to help build and manage a new laboratory. After Hurricane Katrina hit in 2005, Fenwick and his wife relocated their family up to central Illinois as he continued to work in New Orleans. Nearly a year after the hurricane and living apart, he took a position with Archer Daniels Midland Co. in Decatur, Ill., covering ADM’s biodiesel technical services for North America and South America. For nearly the past 10 years of his career, Fenwick has traveled extensively for work, conferences and consulting.

Q: How were you first introduced to biodiesel, and when?

A: I first became acquainted with biodiesel back in the mid- to late-1990s. Several biodiesel facilities were just beginning and submitting initial samples to the lab I was managing in New Orleans to help determine conformance against the ASTM specifications. Some of these biodiesel producers at the time were experimenting with different feedstocks. I’ve jokingly said that some of the samples we received may have even had beaks and feathers still within them. This was a time during which the industry was just starting up and quality was nowhere near what it is today.

Q: You’ve been the technical director at NBB for about a year now. What has been most challenging about the role, and the most rewarding?

A: When you begin to speak about renewable fuels, and biodiesel in particular, there are always questions and concerns over what might still be unknown. Petroleum companies, original equipment manufacturers (OEMs) and users alike all believe that biodiesel is one of the newest fuels in the marketplace and might not be as well understood as traditional petroleum-based fuels. When there is an issue, it must certainly be related to some property of the biodiesel that had been overlooked or even covered up, right? What most consumers don’t realize is that biodiesel got its start in the mid-1990s. Diesel fuel changed in 2006 when the U.S. EPA mandated ultra-low sulfur diesel (ULSD). Compression ignition (diesel) engines today have changed to high-pressure common rail systems and are completely redesigned. One of the biggest challenges is educating fuel users that the performance of biodiesel is as well understood in today’s engines as any traditional petroleum fuel such as ULSD. The most rewarding is the closer working relationship that I have with the larger industry as well as the staff and contractors within the National Biodiesel Board. Not only are they some of the most intelligent and well-respected persons in their individual roles, but they approach each day and challenge with a passion to serve not only our members but also the American public.

Q: Biodiesel quality has improved greatly over the years. To what do you attribute these improvements?

A: I truly believe that the biodiesel industry is interested in making a positive difference in today’s society. The industry is a little more mature today in understanding its own new technologies and production techniques, as well as now having a better understanding of the fuels industry as a whole. The ASTM biodiesel specifications are ever-evolving as we uncover new information about interactions with other fuels and today’s newer engines. In fact, there have been 18 revisions to the D6751 specifications, since the original specifications were published back in 2002. The BQ-9000 programs have helped with quality assurance, but the industry is now to a point where it has begun to police the quality of its own product.

Q: What biodiesel quality-related issues continue to be investigated on a technical level?

A: The National Biodiesel Board continues to manage several technical projects designed to deliver the seamless fuel performance that customers expect. Our members have several opportunities throughout the year to provide feedback on the technical programs they feel are most relevant to the success of the industry. Much of this past year’s feedback has focused upon expanding the possibilities of further market penetration. Besides encouraging industry quality enforcement, we are working on securing B20 approvals within the ASTM heating oil specifications, confirming biodiesel blend stability values for applications with high-pressure common rail engines, confirming the current biodiesel metals limits for engines over their entire useful life with B20, and developing the acceptance of B20 fuels within the railroad industries. Each application has its own unique challenges being studied to provide assurances to users that the increased volumes of biodiesel will not be problematic.

Q: What is the latest biodiesel news on the ASTM front?

A: The most recent ASTM meetings were held this past June in Indianapolis, and we had a record number of ballots relating to or affecting the biodiesel industry. At the forefront were two that I’d like to talk about. We had a ballot to increase the allowable biodiesel content in heating oil, ASTM D396, which currently approves up to 5 percent in No. 1 and No. 2 grades, and we are looking to increase that to 20 percent. The ballot we put forth is one of the most technically comprehensive ballots I’ve ever seen at ASTM. We had information included that basically showed the performance of B20 far outweighed and outperformed the baseline petroleum counterpart—we had fewer leaks from B20, improved emissions and no impacts on performance of the equipment. We did see a few negatives with that ballot, which were more related to the structure of the new specifications and whether it could, or should, be included with the existing specifications or a standalone separate specification. We’re addressing those issues and we will reballot that in December.

The other big one is jet fuel. The biodiesel industry has completed recent studies investigating 400 ppm contamination levels in jet fuel to see if that would have any impact on fuel performance with the idea that we would ballot an increase in the allowable content up from 5 ppm to 100 ppm. The airline trade association, Airlines for America, the military and others are in favor of this increase and have deemed it to not be a flight safety risk. This new limit would allow for pipelines to carry biodiesel blends and still manage safe movement of jet fuel.

Q: OEM approval of higher blends is an essential part of greater biodiesel acceptance. Can you talk about ongoing work in this field?

A: Biodiesel is still considered new to the fuel industry. However, what most people don’t realize is that, while biodiesel has been in the marketplace since the early 2000s, diesel fuel itself had a drastic makeover in 2006 in changing from low sulfur diesel to ULSD. Engines themselves have improved and changed just in the past three to four years as well. The biodiesel industry has prided itself on working with each of the OEMs to answer questions they might have on performance in their new engines. One such example is a current study that we have just begun, looking at fuel stability for biodiesel blends in new high-pressure common rail engines. I’d also like to say that the BQ-9000 commission is working on a new program for retailers that we hope will provide confidence throughout every level of the fuel distribution system and quality assurance for biodiesel blends. The program will audit retailers for tank maintenance, buying fuel from approved sources and things of that nature.

Q: Could you briefly describe how the ASTM spec for biodiesel has evolved over the years, and what has been behind that?

A: There has been a total of 19 versions of D6751 since its inception in 2002—that’s 18 revisions plus the original. Each time the industry has brought forth what it believes to be an issue with biodiesel, we have addressed those with improvements to the specifications (e.g., cold soak filtration, Grade 1 with a monoglyceride limit, etc.). The current biodiesel specifications have approximately 20 parameters to check for fuel quality whereas diesel fuel, under D975, currently has only 13 parameters, so it could be said that there is more strict oversight on biodiesel fuel quality than on diesel fuel.

Q: In your opinion, what are some areas of improvement needed in the ASTM spec for biodiesel?

A: Current and future research will help us answer this better and determine what improvements need to be made. Again, we have an ongoing research project on stability in today’s newer engines. If we find in this study that oxidative stability in biodiesel or blends need to be improved, then we will ballot that.

Q: People often say biodiesel is not a “drop-in” fuel. How do you respond to this?

A: That’s difficult because the term “drop-in” means different things to different people. But at the point of production, whether it’s a petroleum fuel, or biodiesel or another type of renewable fuel, none of them typically meets the specifications without improvement from additives or further blending. Today’s OEMs are coming forth with new concerns about renewable diesel that some might consider to be a “drop-in” fuel. And the ASTM specifications have historically been based upon petroleum refined fuels, so there may be some applications and properties that we’ve taken for granted that we need to go back and review.

Q: A question I get a lot is, “My diesel car is only approved for B5. Will higher blend levels of biodiesel void my warranty?” How do you respond to this?

A: The answer is absolutely not. We do realize some OEMs only approve B5, and blends up to B5 can be legally sold as diesel fuel. Even those prominent OEMs that approve B5 (Volkswagen and Mercedes) have privately issued confirmation letters to registered owners in these states (Illinois where B11 is common) that the use of biodiesel up to B20 will do no harm to their engines and does not void the warranty.

Q: What have been some of the most remarkable technological advances in the history of biodiesel processing?

A: I think there are several. It’s the industry’s ability to adapt, which is not a specific breakthrough, but when cold soak filtration became a part of the specification, our producers quickly learned what it would take for their fuel to meet the new spec. Also, when the industry asked for lower monoglyceride content, National Renewable Energy Laboratory had finished a biodiesel survey across the U.S. and found nearly 90 percent of the industry passed the new mono spec before it was even published. The industry’s ability to process lower-grade, lower-cost feedstock through new technologies such as enzymatic processing, which appears to be taking hold with a few producers across the U.S., and a myriad of other process techniques, is truly remarkable. I call it the Microsoft approach—there’s no one correct answer or means to an end.

Q: Over the years, what have been biodiesel’s greatest technical achievements?

A: It’s important to note that each new study continues to paint a better picture of biodiesel, whether it is greenhouse gas reductions, energy balance, life-cycle analysis or emissions. Each new study comes out with almost continual improvement.

Q: What are the biggest technical challenges that face biodiesel?

Advertisement

Advertisement

A: I think the biggest technical challenge is the biodiesel industry has reached a point in volumes where we’re no longer filling niche markets, but we’re being found across the board. And we need to ensure that biodiesel has the performance characteristics that customers expect. And to date, we have.

Q: How do the technical successes and challenges of biodiesel in the U.S. compare to those around the world?

A: While the U.S. might have initially started behind Europe in production and use of biodiesel, I see the research that we’re doing now taking a lead and being looked at by markets all over the world. For instance, we had discussions earlier this morning with the nation of Colombia regarding biodiesel blend research at 10 percent and the effects on today’s engines. So the research we’re doing not only affects the U.S., but it also affects biodiesel blend performance and fuels all over the world.

Q: Something we heard about several years ago is harmonization of global biodiesel standards. Can you talk about this and what the future holds for harmonization?

A: There have not been any further discussions on harmonization. In fact, the biggest outcome of those discussions in 2007 was that there are rational reasons for the differences we find throughout the global specifications, whether those are attributable to different emissions regulations, regulated sulfur content or cold flow characteristics, each plays an important part in the performance of those fuels on a local or regional basis.

Q: How does the policy uncertainty that biodiesel faces, in the U.S. and internationally, affect progress on the technical front?

A: It slows it somewhat, but it certainly doesn’t prohibit progress on the technical front. RFS2 and other state policies are basically designed as a floor for biodiesel consumption, but hopefully we have markets such as Bioheat along with the desire of industries to move toward better emissions and lower carbon fuels that can create those discretionary blending opportunities to grow beyond that established floor. Hopefully, the work we’re doing on a technical front helps assure confidence in higher concentrations of biodiesel.

Q: If you could change one thing about the biodiesel industry, what would it be?

A: I guess the one thing I would change would be to figure out a way to reach a greater number of people and educate them about the performance and benefits of biodiesel blends. Besides all of the technical work we do, if we can’t communicate that better, then it doesn’t do us any good.

Author: Ron Kotrba

Editor, Biodiesel Magazine

218-745-8347

rkotrba@bbiinternational.com

Advertisement

Advertisement

Related Stories

Clean Fuels Alliance America on June 10 announced the launch of the newly redesigned BQ-9000 website, delivering a streamlined and user-friendly experience that better showcases the value of biodiesel quality assurance.

Pertamina, a national energy company in Indonesia, has successfully condcuted static tests on sustainable aviation fuel (SAF) on CFM56-7B jet engines commonly used in commercial aircraft at GMF Aeroasia's Test Cell facility.

Iowa Central Community College on July 17 broke ground on a an expanded fuel testing lab that will benefit ethanol, biodiesel and other types of fuel. The new biofuel testing lab is expected to be complete in the fall of 2024.

NREL released its Assessment of BQ-9000 Biodiesel Properties for 2022. The report documents the quality of biodiesel from U.S. and Canadian-based producers that participate in the industry's voluntary quality assurance program, BQ-9000.

North American SAF Conference & Expo announces agenda

SAF Magazine and the Commercial Aviation Alternative Fuels Initiative (CAAFI) announced the preliminary agenda for the North American SAF Conference & Expo taking place Aug. 29-30 at the Minneapolis Convention Center in Minneapolis, Minnesota.

Upcoming Events