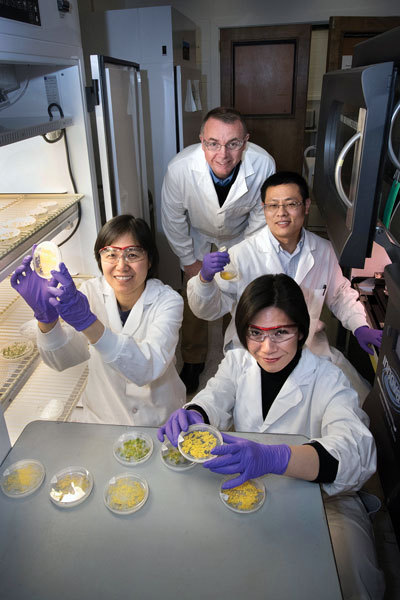

The New Feedstock Frontier

PHOTO: UNIVERSITY OF ILLINOIS URBANA-CHAMPAIGN

May 17, 2018

BY Ron Kotrba

Advertisement

Advertisement

Related Stories

Soil and Water Outcomes Fund receives support from Chevron Renewable Energy Group for climate-smart agriculture advancement

The Soil and Water Outcomes Fund has begun a pilot project with Chevron REG as part of the larger Midwest Climate-Smart Commodity Program. The initiative represents a notable step toward integrating biofuels into sustainable agriculture outcomes.

The U.S. DOE has announced $52 million in funding for six university and industry projects to advance the production of low carbon intensity, purpose-grown energy crops critical to accelerating a clean energy bioeconomy.

CoBank predicts that U.S. production of renewable diesel and associated fuels will experience a modest boost in 2025 but cautions that policy uncertainty looms over administration of the RFS program, SREs and the impact of potential tariffs.

Feedstock State of Affairs

Surging biomass-based diesel feedstock demand has led to a boom in used cooking oil imports, and when combined with current policy mechanisms, U.S. soybean oil is at a disadvantage.

The USDA maintained its forecast for 2024-’25 soybean oil use in biofuel production in its latest World Agricultural Supply and Demand Estimates report, released Dec. 10. The estimate for 2023-’24 soybean use in biofuel was revised down.