Crown unveils innovative pretreatment system for renewable diesel

Photo: Crown Iron Works

January 15, 2020

BY Crown Iron Works

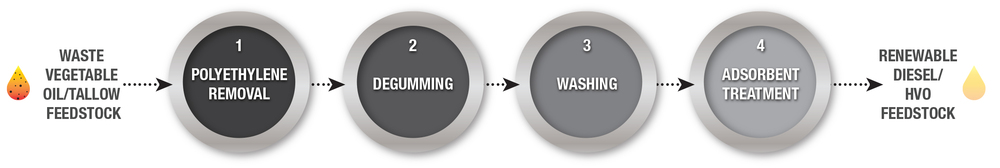

Crown, a global leader in the oilseed processing industry, introduces its game-changing Renewable Diesel Pretreatment System that doubles hydrotreater catalyst life, yields the industry’s highest output of pretreated product, and guarantees product quality specifications, regardless of feedstock.

By maximizing contaminant removal, Crown’s Renewable Diesel Pretreatment System delivers the cleanest possible feedstock to renewable diesel hydrotreaters. Crown’s innovative design can double the lifespan of hydrotreater catalyst, allowing operators to significantly minimize the downtime associated with catalyst changeovers. Engineered to handle any and all contaminants in feedstocks, Crown’s robust, rugged system is proven to reduce phosphorus to less than 1 ppm for vegetable oil feedstocks and tallows, and ensures the lowest levels of polyethylene, metals, chloride and other key contaminants.

Advertisement

With a full guarantee of product quality and contaminant removal to specifications, Crown’s Renewable Diesel Pretreatment System elevates efficiencies and protects renewal diesel investments, now and in the future. Backed by the construction of 50 biodiesel plants, design of six renewable diesel pretreatment plants, and a propriety database of feedstock specs and results, Crown’s Renewable Diesel Pretreatment System is optimized to meet renewable diesel industry standards, can be built to API standards, and is adaptable to changing market requirements.

“Crown’s latest innovation is a slam dunk for renewable diesel operators seeking the cleanest possible feedstock for their hydrotreaters,” says Bill Antilla, the general manager of Crown Global Companies. “With our expertise in process design engineering, we’ve developed a ‘future-proof’ pretreatment system that’s built to accommodate the widest variety of feedstocks and is easily adapted to suit industry and regulatory changes. Crown’s Renewable Diesel Pretreatment System is another shining example of how our Innovation Center is driving industry advancements and helping customers win big by leveraging Crown’s ingenuity to improve their operations.”

Advertisement

The only one of its kind in North America, Crown’s Innovation Center is a 15,000 square-foot fully functional plant offering controlled, confidential piloting to preparation, extraction, refining, biodiesel, renewable diesel, oleochemical and specialty extraction customers around the world. This state-of-the-art facility allows renewable diesel operators to evaluate complex feedstock inputs, test contaminant removal technologies, and stay ahead of market shifts. By tapping into Crown’s deep process engineering knowledge, customers can achieve best-in-class contamination removal at the lowest operating cost, improve decision making with a proprietary database of feedstock specs and renewable diesel pretreatment results, and count on responsive action and innovative problem-solving from Crown’s global team of renewable diesel experts dedicated to providing exceptional service.

Crown, a division of CPM Holdings Inc., is a 141-year-old, Minnesota-based, global company with additional offices in the U.K., Argentina, Brazil, China, Netherlands, Germany, Honduras, Mexico, Russia and Ukraine. Crown currently employs 250 people worldwide.

Related Stories

Biodiesel capacity in the U.S. and Canada dipped slightly stable in 2024, with several renewable diesel producers reporting headwinds and lower margins alongside a drove of SAF projects in various stages of development.

The IEA’s Task 39 group has new research regarding the development and status of the sustainable aviation fuel industry.

The U.S. EPA on Nov. 16 released updated RIN data, reporting that nearly 2.11 billion RINs were generated under the RFS in October, up from 1.81 billion generated during the same month of last year.

Conestoga to host SAFFiRE cellulosic ethanol pilot plant

Conestoga Energy and SAFFiRE Renewables LLC announced on Nov. 16 their agreement for Conestoga to host SAFFiRE’s cellulosic ethanol pilot plant at Conestoga’s Arkalon Energy ethanol facility in Liberal, Kansas.

Officials at Calumet Specialty Products Partners L.P. discussed the company’s proposed plans to boost sustainable aviation fuel (SAF) production at its Montana Renewables biorefinery during third quarter earnings call, held Nov. 9.

Upcoming Events