From Fish Farm to Fuel

July 14, 2008

BY Jerry W. Kram / Photos By Charlotte Southern

While in the minds of many Americans Florida is beaches, Disney World and Cape Canaveral, in reality it is one of the nation's agricultural powerhouses. Biofuels pioneers are looking for ways to take advantage of the bounty of byproducts the state has to offer to feed the energy needs of its expanding population. This has led to the development of projects which would make fuel from citrus peels, sugarcane bagasse and livestock manure. A new project is taking another agricultural operation-fish farming-and using the byproducts to create feedstocks for biodiesel production.

Neptune Industries Inc. and its subsidiaries have come up with a way to solve a long-standing problem in aquaculture-how to keep the fish excreta and uneaten food from becoming a pollution problem, says company Chief Executive Officer Ernest Papadoyianis. The company's invention, called the Aqua-Sphere, keeps this waste out of the environment and collects it so it can be used for other purposes. One of those purposes is algae production for biodiesel feedstock.

Enter the Aqua-Sphere

Neptune Industries, which was founded in 1998, is primarily a technology development company with an emphasis in aquaculture, Papadoyianis says. The company was started by Papadoyianis and his partner and Neptune's chief operating officer Sal Cherch. They first investigated the feasibility of using Florida's quarry lakes for aquaculture-fish farming. The lakes were formed in the pits where limestone and other minerals were mined. "These lakes are an untapped resource," Papadoyianis says. "Most are privately owned and once the mining companies dig down (as far as their permit allows) that's it. After that, they can leave the lake open and pay the taxes on it as an industrial mine, or they can close the mining permit and mitigate the lake, which is expensive. Once you're done it's a liability you have to clean up." Raising fish in the lakes after mining has ceased allows the operation to be zoned as agricultural property and saves a significant amount of money in taxes, postpones mitigation and produces revenue.

Neptune started to raise fish in the lakes using traditional aquaculture equipment, cages and net pens. The company also raises its trademark hybrid striped bass in a land-based raceway system. Testing showed that the water quality in the lakes was good. Pilot projects in three lakes, however, turned up several problems with the equipment. They had high levels of predation and fry escaping as turtles and alligators gnawed through the nets. They also saw that all the fish waste and uneaten feed went out into the lake and hurt the water quality.

"Isolating the crop from the outside environment was a real issue," Papadoyianis says. "The straw that broke the camel's back was when we had a lake turn over." Many lakes have a thermocline, a sharp division between warm, oxygen-rich water near the surface and cold, oxygen-poor water near the bottom. Under certain meteorological conditions, these two layers can mix, causing the oxygen level in the whole lake to plummet. Because the fish weren't isolated from the environment, the operation lost several cages of tilapia and hybrid striped bass in a matter of hours.

Papadoyianis notes that salmon farmers' operations in shallow ocean waters faced similar problems with toxic algae blooms, and pressure from environmental groups and regulators to reduce the waste nutrients going into the environment. "Our vision is that the aquaculture industry is going to be using water acres instead of land acres," he says. "With limited water resources, we feel the future is going to be using what we see as underutilized resources like quarry lakes, impoundments, mineral mines and estuaries.

If you had a system that was eco-friendly you could utilize a lot of areas that right now could not be permitted for aquaculture with net pens because of the pollution."

To solve these issues, the company developed the Aqua-Sphere, a solid walled containment system. The system uses a low-energy, low-head pumping system called an air lift to deliver oxygenated water to the fish and collects waste and uneaten food in a filter system at the bottom. Neptune's land-based fish farm requires a 200 horsepower pump while the air-lift system uses a 2 horsepower blower. The Aqua-Sphere also has hinge points that allow it to flex with ocean currents and waves. Ten 30-foot diameter Aqua-Spheres can produce 1 million pounds of fish per year.

The Future of Fish Farming and Biofuels

Papadoyianis sees the future of traditional aquaculture being limited, somewhat ironically, by a lack of fresh water. Systems that rely on aboveground tanks and groundwater will face increasing competition for resources from industrial and municipal water users. He sees that same competition inhibiting biofuels production. "You have a system where you can take advantage of all these surface water acres," he says. "It could be done not only in quarry lakes but in bays, estuaries and even in the ocean."

Neptune Industries also sees its system as a way for fish farmers to diversify their income. Instead of having a waste stream that contaminates the environment or needs costly disposal, combining the Aqua-Sphere with algae production creates a second income stream by producing feedstock for biodiesel. Papadoyianis also sees benefits to the biodiesel industry as aquaculturists move into algae production. "The way I see it, buying a piece of land and constructing an algae facility and having a whole staff just to produce the algae will make your cost of production go way up," he says. "We are looking at this as a secondary crop that doesn't take a huge secondary investment. For a medium-sized operation you can basically use the same staff as you have for the fish operation.

The process could be diversified even further as the company develops a third product, an insect-based fish food it calls Ento-Protein. The product would replace food currently made from fish meal, which has more than doubled in price since 2006, and is made from insects grown on agricultural waste and industrial coproducts, including distillers dried grains from ethanol plants. Papadoyianis foresees using the algae cake remaining after the oil is extracted as another feedstock for the Ento-Protein operation.

Systems Approach

"We always looked at the Aqua-Sphere with an eye toward full integration, using all the parts of the system," Papadoyianis says. "We never looked at the waste as a liability but rather as an asset." Neptune first used the waste for anaerobic digestion. The waste was pumped into barrels and fermented and the resulting methane was captured. The remaining digested waste was used for producing hydroponic herbs and vegetables. The company's newest application uses the waste to fertilize algae which can be used as a biodiesel feedstock. "Fish waste is a great fertilizer," he adds. "It's not acidic at all like horse and cow manure and you have a lot of nitrogen from the high protein. So it makes a great fertilizer for any plant whether it is algae or seaweed or plants."

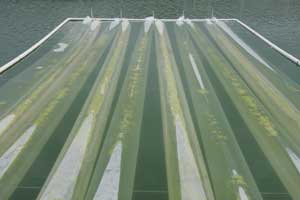

Michael Joubert, the farm's manager, who was interested in the potential of using algae to produce biodiesel, started experimenting with what Papadoyianis calls a floating sock system. "We send the fish waste into these floating algae tubes," Papadoyianis says. "The beauty of the system is that these clear vinyl socks are very, very cheap. You can buy the tubing in huge rolls and it floats on the surface of the water."

Neptune Industry's algae system is uncomplicated and takes advantage of the Aqua-Sphere's environment. Long strips of plastic tubing are suspended on a frame of PVC piping and water and the fish waste fertilizer are circulated through the system. The system floats so the algae get all the sunlight it needs. Because the tubes are partially submerged, the system maintains a constant comfortable temperature for the algae. "It is basically a closed system," Papadoyianis says. "You put the waste, which is the fertilizer, and the algae innoculum in, and it circulates around in a huge manifold. The water traverses literally thousands of feet as it circulates around. It gets the sunlight and keeps cool so you have the best of all possible worlds."

The first test of the system used the dominant species of algae growing in the lake where the company was doing the work. That species wasn't feasible so Neptune is working with an undisclosed company to provide algae species that have high-oil content. The company began testing using the new algae species in mid-June. While Papadoyianis could not say which company was providing the algae innoculum, he did say it was developing systems for extracting algae oil. "It's a good marriage because we are working on the production system and harvesting, and they are working on how to extract and refine that oil," he says. Neptune is still in the design stages of creating a harvesting system that will separate the algae from the water.

Papadoyianis believes Neptune Industries and its partner will be at the point where they can harvest algae and start oil extraction on a test scale before the end of the year. The company has received a three-year grant from the state of Florida to support its work in algae production. Papadoyianis believes the company will have a commercial version of the algae production system up and running well before that grant runs out. "I think in the next 12 months and maybe sooner we will have the system refined and will be able to take it to market as a commercial system," he says.

Among the challenges to scaling up the system will be keeping the algae culture pure, Papadoyianis says. Although the algae socks are a closed system, being submerged in lake water will allow opportunities for native species to contaminate the operation. Another issue of concern is working out the proper amount of waste from the Aqua-Sphere to fertilize the system. But Papadoyianis' main concern is separating the algae from the water after production. "I known we can raise the algae with no problem," he says. "It's going to be the separation that will be the problem."

The work being done by Neptune Industries is being supported by a $158,000 Farm to Fuel Initiative grant from the Florida Department of Agriculture. The company has also been encouraged by Miami and Dade counties as the local governments want to transition all county vehicles to biofuels in the next five years. "They are very, very committed to doing that," Papadoyianis says. "They wrote a nice letter to the state for us supporting our research. So it is a big issue in south Florida."

Jerry W. Kram is a Biodiesel Magazine staff writer. Reach him at jkram@bbibiofuels.com or (701) 738-4962.

Neptune Industries Inc. and its subsidiaries have come up with a way to solve a long-standing problem in aquaculture-how to keep the fish excreta and uneaten food from becoming a pollution problem, says company Chief Executive Officer Ernest Papadoyianis. The company's invention, called the Aqua-Sphere, keeps this waste out of the environment and collects it so it can be used for other purposes. One of those purposes is algae production for biodiesel feedstock.

Enter the Aqua-Sphere

Neptune Industries, which was founded in 1998, is primarily a technology development company with an emphasis in aquaculture, Papadoyianis says. The company was started by Papadoyianis and his partner and Neptune's chief operating officer Sal Cherch. They first investigated the feasibility of using Florida's quarry lakes for aquaculture-fish farming. The lakes were formed in the pits where limestone and other minerals were mined. "These lakes are an untapped resource," Papadoyianis says. "Most are privately owned and once the mining companies dig down (as far as their permit allows) that's it. After that, they can leave the lake open and pay the taxes on it as an industrial mine, or they can close the mining permit and mitigate the lake, which is expensive. Once you're done it's a liability you have to clean up." Raising fish in the lakes after mining has ceased allows the operation to be zoned as agricultural property and saves a significant amount of money in taxes, postpones mitigation and produces revenue.

Neptune started to raise fish in the lakes using traditional aquaculture equipment, cages and net pens. The company also raises its trademark hybrid striped bass in a land-based raceway system. Testing showed that the water quality in the lakes was good. Pilot projects in three lakes, however, turned up several problems with the equipment. They had high levels of predation and fry escaping as turtles and alligators gnawed through the nets. They also saw that all the fish waste and uneaten feed went out into the lake and hurt the water quality.

"Isolating the crop from the outside environment was a real issue," Papadoyianis says. "The straw that broke the camel's back was when we had a lake turn over." Many lakes have a thermocline, a sharp division between warm, oxygen-rich water near the surface and cold, oxygen-poor water near the bottom. Under certain meteorological conditions, these two layers can mix, causing the oxygen level in the whole lake to plummet. Because the fish weren't isolated from the environment, the operation lost several cages of tilapia and hybrid striped bass in a matter of hours.

Papadoyianis notes that salmon farmers' operations in shallow ocean waters faced similar problems with toxic algae blooms, and pressure from environmental groups and regulators to reduce the waste nutrients going into the environment. "Our vision is that the aquaculture industry is going to be using water acres instead of land acres," he says. "With limited water resources, we feel the future is going to be using what we see as underutilized resources like quarry lakes, impoundments, mineral mines and estuaries.

If you had a system that was eco-friendly you could utilize a lot of areas that right now could not be permitted for aquaculture with net pens because of the pollution."

To solve these issues, the company developed the Aqua-Sphere, a solid walled containment system. The system uses a low-energy, low-head pumping system called an air lift to deliver oxygenated water to the fish and collects waste and uneaten food in a filter system at the bottom. Neptune's land-based fish farm requires a 200 horsepower pump while the air-lift system uses a 2 horsepower blower. The Aqua-Sphere also has hinge points that allow it to flex with ocean currents and waves. Ten 30-foot diameter Aqua-Spheres can produce 1 million pounds of fish per year.

The Future of Fish Farming and Biofuels

Papadoyianis sees the future of traditional aquaculture being limited, somewhat ironically, by a lack of fresh water. Systems that rely on aboveground tanks and groundwater will face increasing competition for resources from industrial and municipal water users. He sees that same competition inhibiting biofuels production. "You have a system where you can take advantage of all these surface water acres," he says. "It could be done not only in quarry lakes but in bays, estuaries and even in the ocean."

Neptune Industries also sees its system as a way for fish farmers to diversify their income. Instead of having a waste stream that contaminates the environment or needs costly disposal, combining the Aqua-Sphere with algae production creates a second income stream by producing feedstock for biodiesel. Papadoyianis also sees benefits to the biodiesel industry as aquaculturists move into algae production. "The way I see it, buying a piece of land and constructing an algae facility and having a whole staff just to produce the algae will make your cost of production go way up," he says. "We are looking at this as a secondary crop that doesn't take a huge secondary investment. For a medium-sized operation you can basically use the same staff as you have for the fish operation.

The process could be diversified even further as the company develops a third product, an insect-based fish food it calls Ento-Protein. The product would replace food currently made from fish meal, which has more than doubled in price since 2006, and is made from insects grown on agricultural waste and industrial coproducts, including distillers dried grains from ethanol plants. Papadoyianis foresees using the algae cake remaining after the oil is extracted as another feedstock for the Ento-Protein operation.

Systems Approach

"We always looked at the Aqua-Sphere with an eye toward full integration, using all the parts of the system," Papadoyianis says. "We never looked at the waste as a liability but rather as an asset." Neptune first used the waste for anaerobic digestion. The waste was pumped into barrels and fermented and the resulting methane was captured. The remaining digested waste was used for producing hydroponic herbs and vegetables. The company's newest application uses the waste to fertilize algae which can be used as a biodiesel feedstock. "Fish waste is a great fertilizer," he adds. "It's not acidic at all like horse and cow manure and you have a lot of nitrogen from the high protein. So it makes a great fertilizer for any plant whether it is algae or seaweed or plants."

Michael Joubert, the farm's manager, who was interested in the potential of using algae to produce biodiesel, started experimenting with what Papadoyianis calls a floating sock system. "We send the fish waste into these floating algae tubes," Papadoyianis says. "The beauty of the system is that these clear vinyl socks are very, very cheap. You can buy the tubing in huge rolls and it floats on the surface of the water."

Neptune Industry's algae system is uncomplicated and takes advantage of the Aqua-Sphere's environment. Long strips of plastic tubing are suspended on a frame of PVC piping and water and the fish waste fertilizer are circulated through the system. The system floats so the algae get all the sunlight it needs. Because the tubes are partially submerged, the system maintains a constant comfortable temperature for the algae. "It is basically a closed system," Papadoyianis says. "You put the waste, which is the fertilizer, and the algae innoculum in, and it circulates around in a huge manifold. The water traverses literally thousands of feet as it circulates around. It gets the sunlight and keeps cool so you have the best of all possible worlds."

The first test of the system used the dominant species of algae growing in the lake where the company was doing the work. That species wasn't feasible so Neptune is working with an undisclosed company to provide algae species that have high-oil content. The company began testing using the new algae species in mid-June. While Papadoyianis could not say which company was providing the algae innoculum, he did say it was developing systems for extracting algae oil. "It's a good marriage because we are working on the production system and harvesting, and they are working on how to extract and refine that oil," he says. Neptune is still in the design stages of creating a harvesting system that will separate the algae from the water.

Papadoyianis believes Neptune Industries and its partner will be at the point where they can harvest algae and start oil extraction on a test scale before the end of the year. The company has received a three-year grant from the state of Florida to support its work in algae production. Papadoyianis believes the company will have a commercial version of the algae production system up and running well before that grant runs out. "I think in the next 12 months and maybe sooner we will have the system refined and will be able to take it to market as a commercial system," he says.

Among the challenges to scaling up the system will be keeping the algae culture pure, Papadoyianis says. Although the algae socks are a closed system, being submerged in lake water will allow opportunities for native species to contaminate the operation. Another issue of concern is working out the proper amount of waste from the Aqua-Sphere to fertilize the system. But Papadoyianis' main concern is separating the algae from the water after production. "I known we can raise the algae with no problem," he says. "It's going to be the separation that will be the problem."

The work being done by Neptune Industries is being supported by a $158,000 Farm to Fuel Initiative grant from the Florida Department of Agriculture. The company has also been encouraged by Miami and Dade counties as the local governments want to transition all county vehicles to biofuels in the next five years. "They are very, very committed to doing that," Papadoyianis says. "They wrote a nice letter to the state for us supporting our research. So it is a big issue in south Florida."

Jerry W. Kram is a Biodiesel Magazine staff writer. Reach him at jkram@bbibiofuels.com or (701) 738-4962.

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events