Newton plant to become biorefinery showcase

March 23, 2010

BY Ron Kotrba

Contract negotiations are still being finalized for the arrangement between Elevance Renewable Sciences and Renewable Energy Group Inc.'s 30-MMgy Central Iowa Energy biodiesel refinery in Newton, to co-locate an olefin metathesis demonstration unit with the existing plant for production of a diverse line of biochemicals, renewable jet fuel and enhanced biodiesel. Particular details on the venture, however, are still lacking. Andy Shafer, Elevance executive vice president of sales and marketing, said this is because the company is "managing expectations" of the project until all the pieces in the contract are finalized.

Olefin metathesis is a process that won its three developers-Yves Chauvin, Richard Schrock and Robert Grubbs-the 2005 Nobel Prize in Chemistry, and is applauded for its novel application in organic synthesis with use of ruthenium-based catalysts (also called "Grubbs' catalysts").

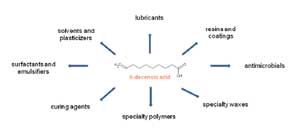

Shafer said the process involves feedstock pretreatment, followed by metathesis and distillation, after which there are different routes to make a number of products, including a variety of olefins for surfactants found in detergents; paraffins for renewable jet fuel; and esters for biodiesel, biobased lubricants and other oleochemicals. Once the technology is in place, Shafer said, it's just a matter of how the plant diverts the stream in order to maximize profitability, taking advantage of existing chemical markets. Elevance refers to biodiesel made from metathesis as "enhanced" because its shorter carbon chain gives the fuel better cold flow properties than traditional biodiesel.

"The technology is commercial today; we're running metathesis by the truckload batch," said Shafer, who added that Elevance sells platform chemicals produced via olefin metathesis to Dow Corning for products such as Victoria's Secret body lotions and soy candle waxes. "But what we haven't done yet-and what we will do at Newton-is commercialize it at an integrated plant site."

The project builder and equipment provider is Technochem. Sanjeev Agarwal, Technochem president, said, "We're providing technical support, equipment, construction, and building of the whole demonstration plant. Details are being worked out now and we hope to have the project complete in a year, but it's hard to predict." The project is different from processes designed and built by Technochem in the past, but Agarwal said it will use familiar components such as distillation. "We're mechanical and chemical engineers, so this project fits in nicely with our areas of expertise," Agarwal told Biodiesel Magazine. "The project is challenging in the sense that it is a new technology. It's exciting to see biodiesel technology develop in this type of application, producing multiple products from the same feedstock, just like a petrochemical refinery can."

In 2007, Newton's local economy was devastated when the Maytag manufacturing plant closed. Derek Winkel, general manager of Central Iowa Energy, said, "This project is exciting, both from an economic development standpoint-getting more jobs here in Newton-and from a technology standpoint."

Olefin metathesis is a process that won its three developers-Yves Chauvin, Richard Schrock and Robert Grubbs-the 2005 Nobel Prize in Chemistry, and is applauded for its novel application in organic synthesis with use of ruthenium-based catalysts (also called "Grubbs' catalysts").

Shafer said the process involves feedstock pretreatment, followed by metathesis and distillation, after which there are different routes to make a number of products, including a variety of olefins for surfactants found in detergents; paraffins for renewable jet fuel; and esters for biodiesel, biobased lubricants and other oleochemicals. Once the technology is in place, Shafer said, it's just a matter of how the plant diverts the stream in order to maximize profitability, taking advantage of existing chemical markets. Elevance refers to biodiesel made from metathesis as "enhanced" because its shorter carbon chain gives the fuel better cold flow properties than traditional biodiesel.

"The technology is commercial today; we're running metathesis by the truckload batch," said Shafer, who added that Elevance sells platform chemicals produced via olefin metathesis to Dow Corning for products such as Victoria's Secret body lotions and soy candle waxes. "But what we haven't done yet-and what we will do at Newton-is commercialize it at an integrated plant site."

The project builder and equipment provider is Technochem. Sanjeev Agarwal, Technochem president, said, "We're providing technical support, equipment, construction, and building of the whole demonstration plant. Details are being worked out now and we hope to have the project complete in a year, but it's hard to predict." The project is different from processes designed and built by Technochem in the past, but Agarwal said it will use familiar components such as distillation. "We're mechanical and chemical engineers, so this project fits in nicely with our areas of expertise," Agarwal told Biodiesel Magazine. "The project is challenging in the sense that it is a new technology. It's exciting to see biodiesel technology develop in this type of application, producing multiple products from the same feedstock, just like a petrochemical refinery can."

In 2007, Newton's local economy was devastated when the Maytag manufacturing plant closed. Derek Winkel, general manager of Central Iowa Energy, said, "This project is exciting, both from an economic development standpoint-getting more jobs here in Newton-and from a technology standpoint."

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events