Biodiesel technology provider helps make brewery carbon-neutral

Photo: BDI-BioEnergy International AG

October 29, 2015

BY Ron Kotrba

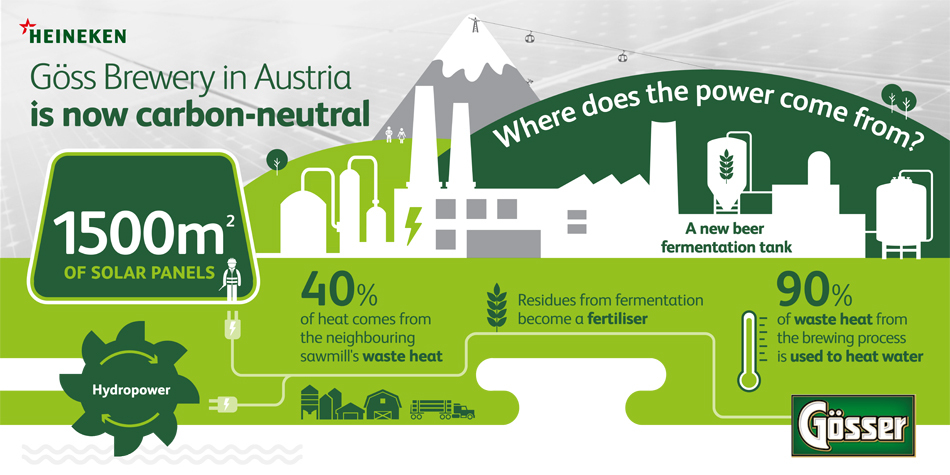

Biodiesel process and biogas technology provider BDI-BioEnergy International AG and Brau Union Österreich, part of the international Heineken family, celebrated the opening of a new spent-grain fermentation plant at the Göss Brewery in Austria, the last milestone in a series of efforts to make the facility 100 percent carbon-neutral. Energy from the brewery’s residual materials will be used for steam generation and excess gas will be converted into renewable electricity. Furthermore, the digestate, a byproduct of the spent-grain fermentation plant, will be used as a high-quality fertilizer.

“With the construction of this industrial spent-grain fermentation plant, we were able, due to the optimal integration of our biogas process, to supply a convincing solution to this environmental project, and thus to help Brau Union Österreich on its way to a completely carbon-neutral plant,” said Edgar Ahn, member of the executive board of BDI-BioEnergy International.

The effort is part of Heineken’s sustainability initiative, “Brewing a Better World.” Since 2003, Göss Brewery started to implement renewable energy in its processes. Energy supply is now 100-percent based on renewable energy and carbon emissions from fossil fuels will be zero. This has been accomplished with electricity from hydropower, biomass district heating, solar thermal energy and renewable energy from the newly built spent-grain fermentation plant from BDI-BioEnergy International.

Nearly 40 percent of the brewery’s heat requirement is met from waste heat discharged from the neighboring Mayr-Melnhof sawmill. Ninety percent of the waste heat generated in the brewing process is used to heat water. A new type of boiling system is used during the brewing process, which helps save electricity and water. A solar plant also helps to generate renewable energy. And now, thanks to the new spent-grain fermentation plant, no more fossil gas will be needed at the complex.

Advertisement

“We are immensely proud that beer production at Göss will in the future be fully CO2-neutral thanks to the beer grain fermentation plant,” said Brau Union Österreich CEO Markus Liebl. “This makes it the first carbon-neutral large-scale brewery in the world.”

Advertisement

Related Stories

Bangkok Airways Public Company Limited has officially announced the adoption of sustainable aviation fuel (SAF) on its commercial flights, reinforcing Thailand’s green aviation industry. The initiative took effect starting July 1, 2025.

Avalon Energy Group LLC and Sulzer Chemtech have signed a strategic alliance and partnership agreement to scale up the production of SAF. Under the agreement, Avalon has selected BioFlux technology for its portfolio of SAF projects.

Neste and DHL Express have strengthened their collaboration with the supply of 7,400 tons (9.5 million liters) of neat, i.e. unblended, Neste MY Sustainable Aviation Fuel to DHL Express at Singapore Changi Airport starting July 2025.

CoBank’s latest quarterly research report, released July 10, highlights current uncertainty around the implementation of three biofuel policies, RFS RVOs, small refinery exemptions (SREs) and the 45Z clean fuels production tax credit.

The U.S. Energy Information Administration maintained its forecast for 2025 and 2026 biodiesel, renewable diesel and sustainable aviation fuel (SAF) production in its latest Short-Term Energy Outlook, released July 8.

Upcoming Events