Honeywell UOP technology powers largest US advanced biofuel plant

Source: UOP LLC

May 15, 2014

BY UOP LLC

UOP LLC, a Honeywell company, announced May 15 that its trademarked UOP/Eni Ecofining process technology is powering the largest commercial advanced biofuel facility in the U.S., capable of producing more than 130 MMgy of renewable diesel.

The Diamond Green Diesel facility in Norco, La., converts inedible oils and other waste feedstocks to produce high-quality renewable diesel, also known as Honeywell Green Diesel. Renewable diesel produced using the UOP process is chemically identical to petroleum-based diesel and can be used as a drop-in replacement in vehicles with no modifications. Renewable diesel produced using the Ecofining process also features up to an 80 percent lifecycle reduction in greenhouse gas emissions compared with diesel from petroleum.

The facility, a joint venture of Darling International Inc. and Diamond Alternative Energy LLC, a subsidiary of Valero Energy, achieved all of its performance and quality targets.

Advertisement

Advertisement

“Commercial production at the Diamond Green Diesel facility is a significant milestone for the renewable energy industry,” said Veronica May, vice president and general manager for Honeywell's UOP renewable energy and chemicals business unit. “UOP has leveraged 100 years of refining technology to make real alternative fuels, including Honeywell Green Diesel and Honeywell Green Jet Fuel, from a range of inedible biofeedstocks.”

John Roach, senior vice president at Valero, said, “Both the performance of the Ecofining unit and the quality of the diesel produced has exceeded our expectations.”

Randall C. Stuewe, chairman and CEO at Darling, said, “The availability of sustainable feedstocks is a key driver for the continued growth of renewable fuels. One of the benefits of the Ecofining process is that the technology is capable of processing a variety of feedstocks collected and manufactured by Darling to produce high-quality Green Diesel.”

Advertisement

Advertisement

Fuel produced at the facility is designed to meet the U.S. EPA’s renewable fuel standard (RFS), which requires a minimum volume of transportation fuels sold in the U.S. to contain renewable fuel to help reduce greenhouse gas emissions. The Diamond Green Diesel facility will produce more than 200 million ethanol-equivalent-gallons per year of biomass-based diesel as defined under the RFS.

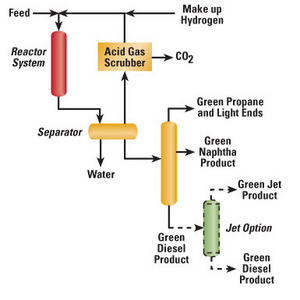

UOP and Eni SpA jointly developed the Ecofining process, which uses hydroprocessing technology to convert inedible natural oils and animal fats to Honeywell Green Diesel. The fuel offers improved performance over petroleum-based diesel, including a high cetane value of 80 compared with a cetane range of 40 to 60 found in diesel at the pump today. Cetane value is the measure of the combustion quality of diesel. Higher cetane values help diesel engines operate more effectively. Diesel with high cetane can be blended with low-cetane diesel to help meet transportation requirements. Honeywell Green Diesel also offers high energy density and excellent performance at cold or warm temperatures.

In addition to Ecofining technology, the company has commercialized the UOP Renewable Jet Fuel Process, which was originally developed under a contract with the U.S. Defense Advanced Research Projects Agency to produce renewable jet fuel for the U.S. military. Honeywell Green Jet Fuel produced by this process technology can be blended seamlessly with petroleum-based fuel. When used in up to a 50 percent blend with petroleum-based jet fuel, Honeywell Green Jet Fuel requires no changes to aircraft technology and meets all critical specifications for flight.

UOP is also a partner with Ensyn Corp. in Envergent Technologies LLC, which offers RTP rapid thermal processing technology and equipment for the production of renewable heat, power and transportation fuels.

Related Stories

Biodiesel capacity in the U.S. and Canada dipped slightly stable in 2024, with several renewable diesel producers reporting headwinds and lower margins alongside a drove of SAF projects in various stages of development.

The IEA’s Task 39 group has new research regarding the development and status of the sustainable aviation fuel industry.

The U.S. EPA on Nov. 16 released updated RIN data, reporting that nearly 2.11 billion RINs were generated under the RFS in October, up from 1.81 billion generated during the same month of last year.

Conestoga to host SAFFiRE cellulosic ethanol pilot plant

Conestoga Energy and SAFFiRE Renewables LLC announced on Nov. 16 their agreement for Conestoga to host SAFFiRE’s cellulosic ethanol pilot plant at Conestoga’s Arkalon Energy ethanol facility in Liberal, Kansas.

Officials at Calumet Specialty Products Partners L.P. discussed the company’s proposed plans to boost sustainable aviation fuel (SAF) production at its Montana Renewables biorefinery during third quarter earnings call, held Nov. 9.

Upcoming Events