The Effect of Feedstocks on InfraRed Blend Measurements

January 18, 2012

BY Sandra Rintoul

With biodiesel hitting a new production record of 823 million gallons through October and expected to reach 1.28 billion by 2013, more biodiesel will ultimately be blended into our diesel fuel. This boom in production has opened the doors to a number of potential biodiesel feedstock sources from algae and jatropha to grease from food production or municipal waste.

More blends mean an increased need to measure the ratio of biodiesel in petro diesel. Infrared technology, used in both the European EN14078 and the ASTM D7371 methods, offers a quick and easy way to make the measurement.

Biodiesel Feedstocks and Measurement Accuracy: A common concern of individuals measuring the percent of biodiesel in diesel is if different feedstock will affect the blend analysis. Knowing more about how mid-infrared analysis detects biodiesel and the chemical structure of the feedstock oils will help show that infrared is a convenient and accurate tool for blend determination.

Advertisement

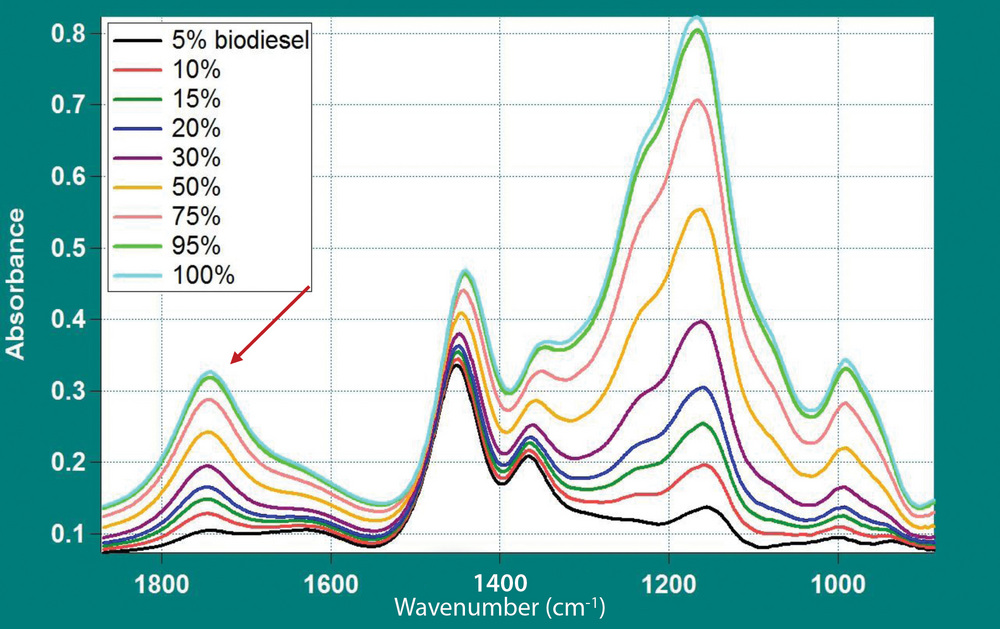

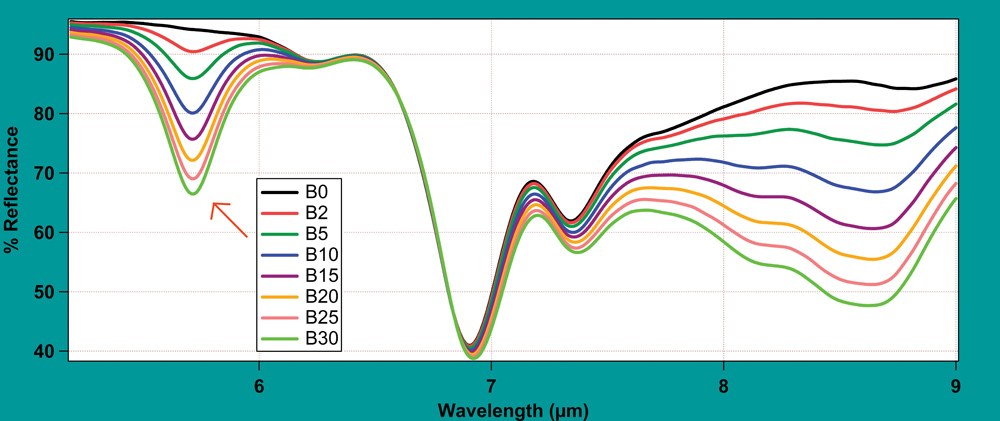

How Does Infrared Measure Biodiesel Content? Fortunately for manufacturers of infrared instrumentation, biodiesel has a unique signature from diesel in the infrared range of the spectrum at the carbonyl band (5.73 micrometers or 1745cm-1). Carbonyl infrared absorbance is due to the stretching vibration of the carbon-oxygen double bond (C=O). At this infrared wavelength specific to biodiesel, the intensity of the absorbance increases as the concentration of biodiesel increases (see Figure 1). Calibration standards of different biodiesel blends are used to correlate the infrared absorbance to a percent concentration. In general, the wavelength and intensity of a carbonyl absorption will be affected by the mass and nature of the atoms attached to the C=O group.

What Effect Does the Feedstock Have on Finished Biodiesel? The primary difference between the fatty acid esters in oils from various feedstocks is the length of the hydrocarbon chains and the number and position of the C=C bonds (carbon-carbon double bond). Most feedstocks such as soy, canola and yellow grease (or waste vegetable oil, WVO) have chain lengths between C16 and C22 with C18 predominating. The chain lengths and their position affect cold flow properties such as the cold filter plugging point and cloud point.

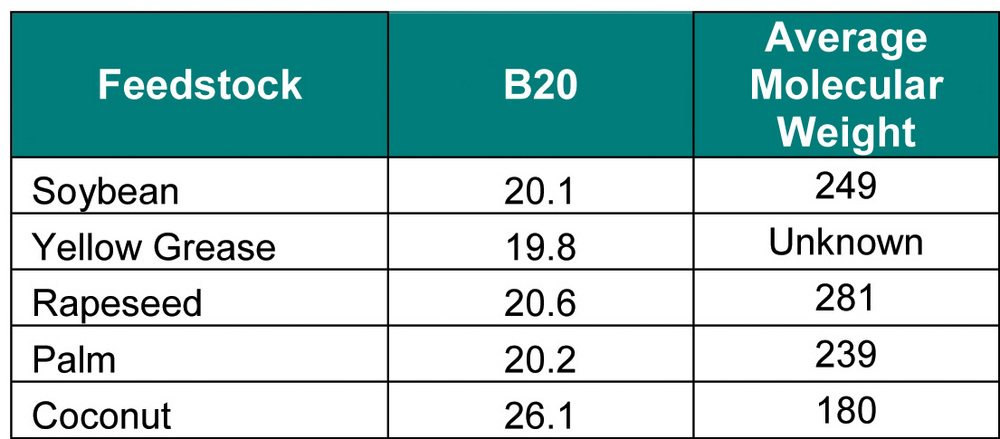

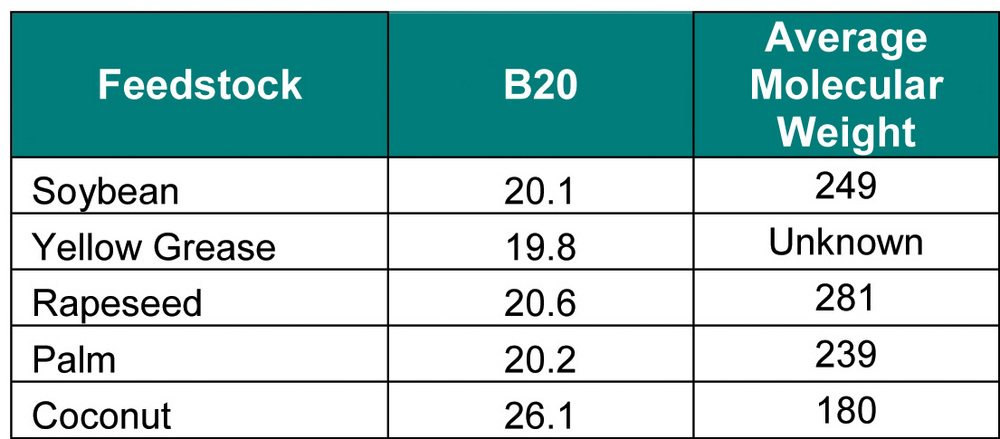

How Do the Differences in Feedstock Affect Infrared Measurements? As mentioned above, the wavelength and intensity of a carbonyl absorption will generally be affected by the mass and nature of the atoms attached to the C=O group. Table 1 shows that the average molecular weight (mass) for five different feedstock oils is very similar for all except one. Different chain length means that the chains have different masses. These aliphatic chains, however, are quite flexible so that a few carbon atoms more or less at the end far removed from the carbonyl group will have no significant affect on the infrared absorption. When C=C bonds are present (unsaturated oils) they are found near the center of the chain, i.e., far removed from the carbonyl group, so they too have little effect on the carbonyl absorption.

Advertisement

How Does This Translate to the Primary Concern of Whether Your Biodiesel Blend Measurements Will Be Accurate? Table 1 shows the results from a B20 blend with five different feedstocks measured with a Wilks InfraCal Biodiesel Blend Analyzer. As indicated in the B20 column, most of the feedstocks are measured quite easily by infrared analysis with the exception of coconut oil.

The third column of the table shows the average molecular weight of the fatty acid methyl ester (FAME). Notice that the coconut oil is significantly different from the other oils with a molecular weight of 180. According to the molecular weight, the coconut-based FAME should give a response of about 26.1 percent. Any infrared analyzer can be calibrated specifically for a coconut oil so the concentration measurement will be correct in spite of the molecular weight difference. Conveniently, the biodiesel made from coconut oil does not perform well in cold or temperate climates so its use is restricted to more tropical parts of the world.

While the development of new nonfood crops as well using oils from meat packing plants or municipal and industrial wastes as feedstock is perpetually in the news, none have yet made a significant inroad into the marketplace. As these new feedstocks enter large-scale production, keeping an eye on the average molecular weight will help determine if the infrared blend results will be in line with traditional feedstocks or if the calibration needs to be updated to obtain accurate measurements.

Since mid-infrared measurements are compatible for a majority of the biodiesel feedstocks, it is a simple and reliable analytical technique for checking biodiesel blend. The technology lends itself to compact and easy-to-use analyzers that enable petroleum terminals, fuel distributors, fleet operators and regulatory agencies to make quick, on-site or laboratory measurements with little or no technical training.

Author: Sandra Rintoul

President, Wilks Enterprise Inc.

(831) 338-7439

Srintoul@WilksIR.com

Upcoming Events