MSU, PHYCO2 collaborate on algae growth demonstration project

March 6, 2013

BY PHYCO2

PHYCO2, an emerging algae growth and carbon dioxide sequestration company, and Michigan State University have announced a partnership designed to generate sustainable, clean energy sources through a new method to produce algae.

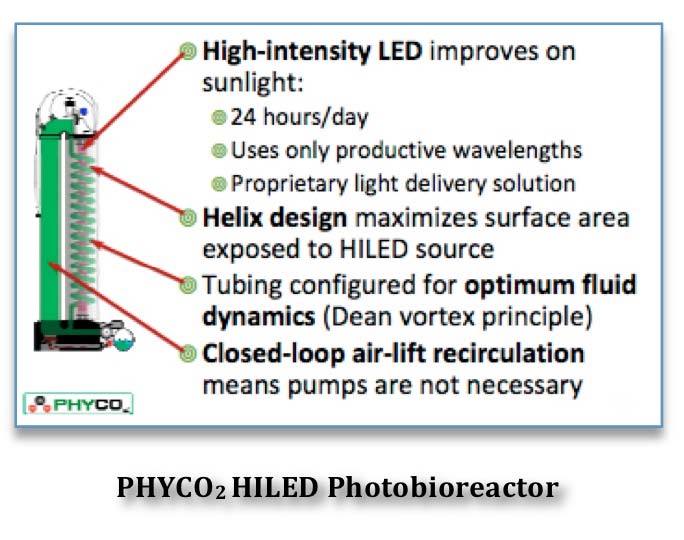

The partnership will demonstrate the patent-pending PHYCO2-developed technology to sequester CO2, reclaim water and continuously grow multiple types of algae at an accelerated rate without sunlight. The goal of the demonstration project is to meet the growing demand for algae for biofuels, pharmaceuticals, foods and other purposes.

PHYCO2 developed this technology to overcome current industry restraints such as limited access to sunlight, slow algae production rates, contamination risks and space restrictions. The technology can capture harmful greenhouse gas emissions while producing large volumes of biomass and clean oxygen.

Advertisement

“The formation of this partnership with MSU further confirms not only the viability of our leading algae technology, but signals a clear path to commercialization,” said PHYCO2 CEO Gregory Hagopian.

“This project allows us to be where we thrive—on the cutting edge of technology,” said Robert Ellerhorst, director of utilities at the MSU Power Plant. “This joint effort is one of several steps in MSU’s efforts to make significant reductions in greenhouse gas emissions from our campus power plant.”

The Dow Chemical Co. played a notable role in forging the partnership and will validate the performance, mass and energy balance of these demonstrations throughout the 18-month project, which is currently underway at MSU.

“At Dow, we continue to be interested in all technologies that can offer options for capture and recycle of CO2 and we look forward to following the progress of the demonstration project,” said Michael Mazor, Dow Energy Solutions research fellow.

Advertisement

Researchers are hopeful the new technology will allow them to begin serious efforts to use algae in fields that desperately need alternative energy sources.

The technology will be tested at MSU’s Pilot Anaerobic Digestion/Algal Cultivation Facility located in the T.B. Simon Power Plant, in coordination with researchers Wei Liao and Susie Liu, faculty members in MSU’s Department of Biosystems and Agricultural Engineering. The facility was built to comprehensively research and develop anaerobic digestion, algal cultivation, and associated technologies with emphasis on bioenergy production and environment protection. The facility includes a half-acre algal open-pond, a 250,000-gallon bioreactor, and two 1,000-square-foot laboratories equipped with advanced analytical instrumentation.

Related Stories

The USDA reduced its estimate for 2024-’25 soybean use in biofuel production in its latest WASDE report, released May 12. The agency expects soybean oil use in biofuel to increase during the 2025-’26 marketing year.

HutanBio's microalgal biofuel production shown to be net-negative in an independent life cycle assessment by EcoAct

HutanBio on May 8 announced that the production process for its proprietary HBx microalgal biofuel achieves net-negative carbon emissions, based on an independent cradle-to-gate life cycle assessment (LCA) conducted by EcoAct.

According to a new economic contribution study released by the Iowa Renewable Fuels Association on May 6, Iowa biofuels production has begun to reflect stagnant corn demand throughout the agriculture economy.

Repsol and Bunge on April 25 announced plans to incorporate the use of camelina and safflower feedstocks in the production of renewable fuels, including renewable diesel and sustainable aviation fuel (SAF).

U.S. operable biofuel capacity in February was unchanged from the previous month, according to data released by the U.S. EIA on April 30. Feedstock consumption for February was down when compared to both January 2025 and February 2024.

Upcoming Events