Utah's Young Biodiesel Phenom

PHOTO: GRAYDON BLAIR, UTAH BIODIESEL SUPPLY

May 1, 2013

BY Ron Kotrba

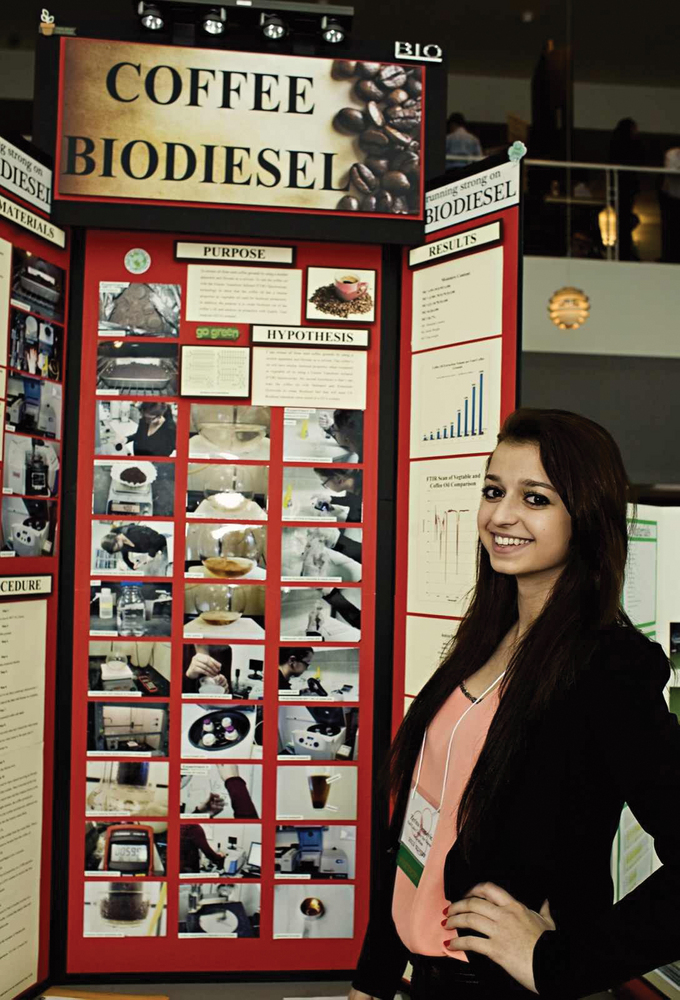

To those who have lost hope in the future of American youth as statistics suggest U.S. high school students lag far behind their international peers in math and science, meet Zerina Ocanovic. Just a high school sophomore at the Salt Lake Center for Science Education in Salt Lake City, Utah, Ocanovic has done, and won, more science fairs and competitions than most of us could ever dream. Her desire to experiment, learn and compete in major contests against stiff opposition has opened up a very bright future for this determined, up-and-coming scientist. Much of her work has been in renewable energy and biodiesel experimentation.

“When I was in fourth grade, one of my teachers got me into doing science fair projects,” Ocanovic says. “Each year, I did an experiment. When I became a sixth grader, I did a project comparing biodiesel created from different vegetable oils. From there, my passion for renewable energy grew.”

For her first biodiesel science fair project, Ocanovic reached out to Graydon Blair, owner of Utah Biodiesel Supply. “When she came over, her excitement for the project and zeal to do a thorough job were outstanding,” Blair says. “She made several samples of biodiesel and tested them for various things like cold flow, heat Btu and more. She goes above and beyond in making sure her projects are well-researched, well-tested, and then takes the extra step to ensure she thoroughly understands every aspect of the project material.” Ocanovic won first place.

In middle school, Ocanovic branched out her science fair experiments into ethanol and microbial fuel cells. “When I grow up, I think I would like to study in the field of engineering,” Ocanavic tells Biodiesel Magazine. “I would like to become an engineering manager and create environmentally friendly products. I would love to be able to help Utah reduce its pollution.” Biomedical engineering also interests the young Ocanovic. “Often I go with my grandpa to his doctor appointments, and I translate for him,” she says, adding that her family came to the U.S. from Bosnia and Herzegovina in April 1997. She was born three months later. Last summer, Ocanovic was an unpaid intern at the University of Utah bioengineering lab.

As a freshman, Ocanovic raised the already high science experiment bar by growing algae fertilized with urine, extracting the oil and making biodiesel. That project won Ocanovic second place in the Salt Lake City School District, and first place in the Salt Lake Valley Science and Engineering Fair. Her prize was an $80,000 scholarship to Westminster College in her hometown. Ocanovic went on to Intel’s International Science and Engineering Fair in Pittsburgh, Pa., where she competed against more than 1,500 projects from 68 countries.

Ocanovic didn’t rest on her laurels, though. She was back in the lab, putting in overtime trying to extract oil from used coffee grounds, once again pushing herself to the limit. “I decided to extract oil from used coffee grounds by using a Soxhlet apparatus and hexane as a solvent,” Ocanovic says. She tested the coffee oil with a Fourier Transform Infrared spectroscope to show that the oil has properties similar to vegetable oils. “I decided to create biodiesel out of the coffee oil and analyze its properties with [Eurofin’s] Quality Trait Analysis scanner,” she says. “With this project, I was able to go on to Salt Lake City School District and compete. I won first place.”

Advertisement

Ocanovic has also received accommodations and recognition from the U.S. Navy, the U.S. Air Force, the American Society of Civil Engineers, the American Institute of Aeronautics and Astronautics, the Office of Naval Research Science, and from the National Society of Professional Engineers.

Algae Work Details

For her algae experiment, Ocanovic used Scendesmus dimorphus. “I grew my algae in three different media—phosphate, urine and nitrate—for two weeks,” she says. “Then I took 500 milliliters (ml) of each media sample with algae and put in three 500 ml labeled, plastic bottles. Then I put each sample in a centrifuge machine for five minutes to separate algae from media. I took the bottles out of the centrifuge and poured all the liquid media out of the bottles so that only the algae cultures—algae paste—were left in the bottles.”

Then she transferred the algae paste from each plastic bottle into labeled test tubes. She capped the tubes and froze them for four days in the freezer at -80 degrees Centigrade. All three samples were freeze dried so she could crush each dried sample into fine algae powder, then they were weighed and put into labeled sampling tubes. “Then I created a methanol-sulfuric acid solution,” Ocanovic says.

“Two ml of this solution was added to each of the testing tubes with powered algae samples. Each sample was mixed on vortex machine and then put in oven on 100 degrees C for 15 minutes for the reaction to take place. I added 3 ml of hexane to each powdered algae samples and mixed them on the vortex machine for another 5 seconds. Then I put them in centrifuge for 15 seconds for everything to separate.”

Proteins, carbohydrates and sulfuric acid fell to the bottom, Ocanovic says, adding that the second layer was methanol and the top layer was algae oil mixed with hexane. “I took the top portion of each sample and tested it in the gas chromatograph machine for biodiesel properties,” she says. “The challenges that algae experiment posed for me were that I grew algae in small containers and was able to produce just a small amount of oil.” Ultimately, Ocanovic grew about 1 gallon of algae and was left with about three drops of biodiesel that were tested in the gas chromatograph.

The Coffee Grind

Advertisement

Blair says after the award-winning algae work, Ocanovic contacted him again about researching the viability of making biodiesel from coffee grounds. “Her drive to make sure she thoroughly understood the chemistry, math and science behind the biodiesel reaction was amazing,” Blair tells Biodiesel Magazine.

Ocanovic obtained used coffee grounds from a local coffee shop. She used some equipment from her school, the Salt Lake Center for Science Education, but she had to buy a Soxhlet extraction apparatus online. “Tony Butterfield, a professor at the department of chemical engineering at the University of Utah supervised me,” she says. “He allowed me to use his lab for the experiment and he provided me with hexane. I searched online to see if there were any biodiesel experts to help me test my coffee biodiesel samples. I then found Washakie Renewable Energy. Brian Mattingly, the plant manager, and his workers were so nice. I cannot express how much help and support I received from them. Also, Eddie Hall was very nice, he was the person who turned on the QTA for me to use.” She says the QTA equipment was easy to use and gave her results in less than two minutes. “It was amazing how the machine needed just one drop of my sample to give me so much information,” she says.

Hall with Eurofins QTA says the 10 MMgy Washakie Renewable Energy plant in Plymouth, Utah, uses QTA for process quality control. “Brian Mattingly had asked if Zerina could use QTA for her process,” Hall says. “We were excited to support Zerina’s efforts. She used the QTA to test the oil extracted from the coffee grounds and then her finished product after converting the oil to biodiesel. It is very exciting to see Zerina’s initiative. We at QTA believe that she has a very bright future.”

The coffee project was not without its challenges. “I kept researching, and I kept failing in my attempts to make oil, but I did not give up,” Ocanovic says. “I just believed in my research. Every time I failed, I just pushed myself more. Some nights I stayed up until 2 or 3 a.m. in my kitchen experimenting and trying different stuff until I figured it out. I felt that both my projects were challenging. However, with both projects, I felt that there were people willing to help me. That made a difference. They all went beyond what I expected from them. Furthermore, I want to mention that Graydon Blair from Utah Biodiesel Supply was also a mentor. He has actually been mentoring me since my first project that involved biodiesel.”

“Together we tested the oil and made a couple mini batches of biodiesel,” Blair says, “but she didn't just rely on the work she did with me. Instead, she duplicated all the work again to make sure she had a thorough understanding of how everything worked and operated, and then had everything reanalyzed.” He continues, saying, “If Zerina is any indication of what our future scientists and biodiesel researchers are going to be like, then I'm really excited for the future,” Blair says. “She truly has been a great example of what can be done when you put your mind to looking for new ways to solve our energy problems. The fact that her latest research was based on biodiesel from used coffee grounds is the icing on the cake!” Mattingly says, “Zerina is a very talented young student. I was impressed by her professionalism and by her knowledge of biodiesel.”

When asked how she finds time for all of this intense research and competition, Ocanovic says, “It’s very hard actually. I’m a sophomore. High school in general is stressful, but I always choose to push myself out of my comfort zone. Doing science fairs was never mandatory for me. I always chose to do it on my own time. My main goal was to express my passion for our environment.”

Author: Ron Kotrba

Editor, Biodiesel Magazine

218-745-8347

rkotrba@bbiinternational.com

Related Stories

The USDA on April 14 announced the cancellation of its Partnerships for Climate-Smart Commodities program. Select projects that meet certain requirements may continue under a new Advancing Markets for Producers initiative.

The USDA reduced its outlook for 2024-’25 soybean oil use in biofuel production in its latest World Agricultural Supply and Demand Estimates report, released April 10. The outlook for soybean oil pricing was revised up.

BDI-BioEnergy International has signed a contract with Ghent Renewables BV to begin the construction of a pioneering biofuel feedstock refinery plant. Construction is underway and the facility is expected to be operational by the end of 2025.

Gevo subsidiary announces agreement with Minnesota Soybean Processors to track and verify sustainable agriculture attributes

Verity Holdings LLC, a subsidiary of Gevo Inc., has partnered with Minnesota Soybean Processors (MnSP) to implement Verity’s proprietary track and trace software. The collaboration aims to unlock additional value through export premiums.

U.S. operatable biofuels capacity increased slightly in January, with gains for ethanol, according to the U.S. EIA’s Monthly Biofuels Capacity and Feedstock Update, released March 31. Feedstock consumption was down when compared to December.

Upcoming Events