Tenn. researchers develop 5 ppm FAME detector for jet fuel

August 21, 2013

BY Ron Kotrba

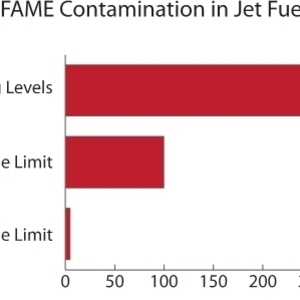

Millions of dollars and years of testing have already been invested in the attempt to increase ASTM’s allowable amount of fatty acid methyl ester (FAME) contamination in jet fuel, which can occur from pipeline movement of diesel containing low-level biodiesel blends followed by jet fuel. At high concentrations, biodiesel contamination in jet fuel may impact the thermal stability of the fuel, leading to coke deposits in the fuel system. Contamination can also impact the freezing point of jet fuel, resulting in gelling. Such conditions may result in engine operability problems and possible engine flameout. The current amount of biodiesel contamination allowed in ASTM D1655, the jet fuel spec, is up to 5 parts per million (ppm), a level so low that traditional analytical equipment such as gas chromatography, Fourier transform infrared and high-performance liquid chromatography cannot detect.

“Allowing a higher level of biodiesel in the ASTM specifications for jet fuel than 5 ppm will make it much easier for pipelines to manage shipments of biodiesel blends in a manner that ensures jet fuel will always meet the specifications,” said Steve Howell, senior technical advisor with the National Biodiesel Board. The U.K.-based Energy Institute is leading a large consortium of interested parties to conduct testing (at 400 ppm, or four times the proposed allowable limit) needed by jet engine OEMs, the Airframe OEMs and the U.S. Federal Aviation Administration to support up to 100 ppm biodiesel contamination in jet fuel.

While those involved wait for report to be published soon, which will be reviewed and used to help determine the path forward at ASTM, researchers at the University of Tennessee have developed thin-film sensors with high sensitivity toward biodiesel contamination in jet fuel. Small strips of these sensors have been tested to detect the trace biodiesel contaminant in diesel at as low as 0.5 ppm in less than 30 minutes. The sensor also gives quick response to B20 in less than five minutes and may be used with the naked eyes.

The sensors, developed by UT chemistry professor Ziling Xue and doctoral student Jonathan Fong, are intrinsically small, easy to use, inexpensive, and can be mass-produced for disposable applications. When combined with a portable reader, the sensors can be potentially used as a compact portable device for field applications.

Advertisement

Advertisement

A report on the sensors, “A dye-doped optical sensor for the detection of biodiesel in diesel,” was recently published and can be accessed here.

The university is seeking partners to commercialize the technology.

Advertisement

Advertisement

Related Stories

Airbus is taking a significant step toward scaling the adoption of sustainable aviation fuel (SAF) by testing a new “Book and Claim” approach. This initiative aims to boost both supply and demand for SAF worldwide.

Signature Aviation, the world’s largest network of private aviation terminals, has announced the expansion of its blended SAF offering at six new locations across Europe following multiple blended SAF supply agreements.

Virgin Australia has entered an agreement with Viva Energy to SAF for its flights departing from Proserpine, Queensland. The SAF will consist of Jet A1 and a 30-40% synthetic blend component made from waste and residue feedstocks.

The largest single volume order of sustainable aviation fuel (SAF) by a DB Schenker customer has been placed by Mercedes-Benz. The order is for approximately 13,000 metric tons of SAF and is expected to reduce CO2 emissions by 40,000 metric tons.

ADM and Loyola University Chicago Searle Biodiesel Lab have joined the expanding B20 Club. Founded in 2014, the B20 Club is a partnership between the Illinois Soybean Association and American Lung Association.

Upcoming Events