Cold Flow Treatment: FAME, HVO & Diesel Blends

PHOTOS: CLARIANT

October 28, 2013

BY Werner A. Reimann and Bettina A. Siggelkow

The recent two decades have been a period of constant change for diesel fuel specifications. The main driving forces have been initiatives to reduce vehicle emissions and, later, efforts to find access to renewable and sustainable resources with the aim of minimizing diesel fuel’s CO2 footprint while at the same time becoming independent of fossil feedstocks. Europe has been at the forefront of this revolutionary trend and is still at the leading edge of these developments.

Quota politics began in Europe in 2003 when the biofuel directive was issued by the European Parliament and Council. The biofuel directive required a minimum biofuel quota of 2 percent beginning in 2005 and envisaged a stepwise increase to 5.75 percent by 2010. However, revised regulations became more ambitious and in line with the current EU directives, leading to today’s biodiesel quota, which is now at 7 percent with the declared target of reaching 10 percent by 2020.

The quotas did stipulate blends of mineral diesel and biodiesel, so at first the majority of biodiesel was sold as B100. Only later, when tax relaxations were alleviated, did selling standard B100 became unprofitable and refiners started using biodiesel as a blending component.

The major part of the biodiesel quota in Europe is still covered by first-generation fatty acid methyl ester (FAME) biodiesel, but recent fiscal legislation has made it possible for more second-generation biodiesel (HVO) to be brought into the market. Recent reconsiderations by the European council suggest capping the quota of edible vegetable oils processes to 6 percent with the gap in 2020 targets to be made up by alternative feedstock with no land use change/indirect land use change issues.

Europe embraces a wide range of climatic zones where single or combined use of FAME and HVO as a blending component is practiced. Cold flow treatment of the various kinds of biodiesel and blends with mineral diesel is of key importance for this industry.

Cold Flow Treatment of B100

First-generation biodiesel is referred to as FAME. It’s obtained from fats, oils or greases by transesterification with methanol leading to glycerol as a side product. In Europe, the most common feedstocks are rapeseed, soybean and palm oils, with used cooking oils becoming more popular and profitable in recent years.Vegetable oils contain certain amounts of saturated fatty acids that are mainly found in the chain length of C14, C16 and C18. Depending on the species of plant origin, the content of saturated fatty acids in the oil or fat can make up more than 50 percent.

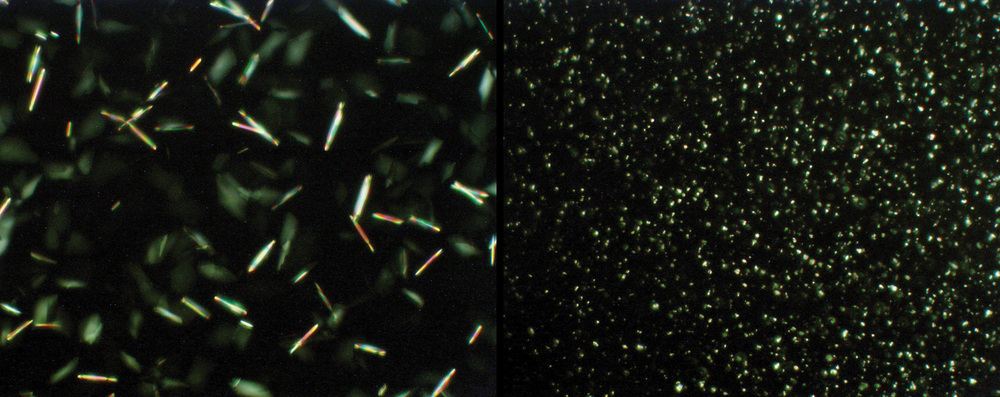

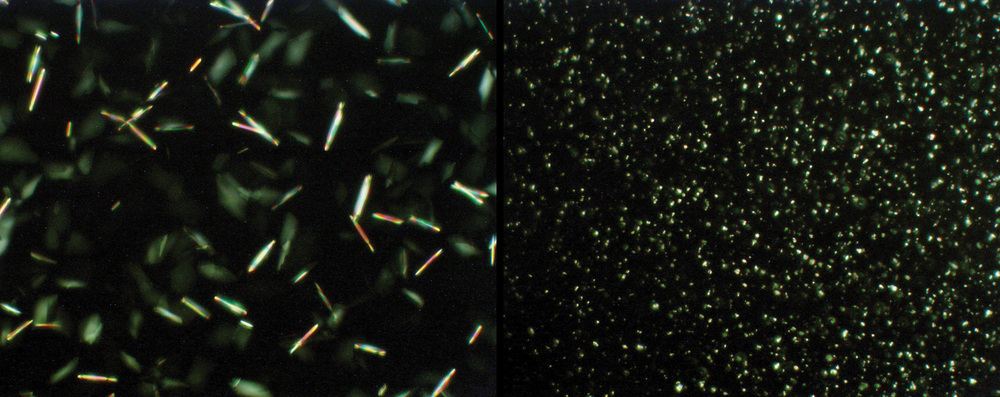

The saturated fatty methyl esters are responsible for the cold flow and engine operability problems in the cold. Saturated fatty methyl esters, which are very similar to the linear paraffin in mineral diesel, will start to crystallize and drop out of solution upon cooling. This crystallization creates field problems similar to vehicle operability experienced in the past. During the crystallizing process, the saturated FAME molecules in the biodiesel are forming macrocrystalline structures that can block filter screens. Often this is found in internal combustion engines and can sometimes permeate through the whole of the fuel, causing it to form a solid gel.

This can create a serious problem in the distribution chain, because when B100 is transported to refineries or terminals to be used as a blending component, it often forms sediments or solidifies.

Saturated FAME crystal growth can be effectively controlled by the use of biodiesel flow improvers that hinder the crystals to form large interlocking species and produce very small crystal entities that can be readily dispersed.

Advertisement

Advertisement

Basic cold-flow properties of biodiesel are measured in the same way for mineral diesel. The cloud point (CP) is the temperature where the biodiesel gets turbid; the cold filter plugging point (CFPP) indicates the engine operability limit and the pour point (PP) reflects the solidification temperature.

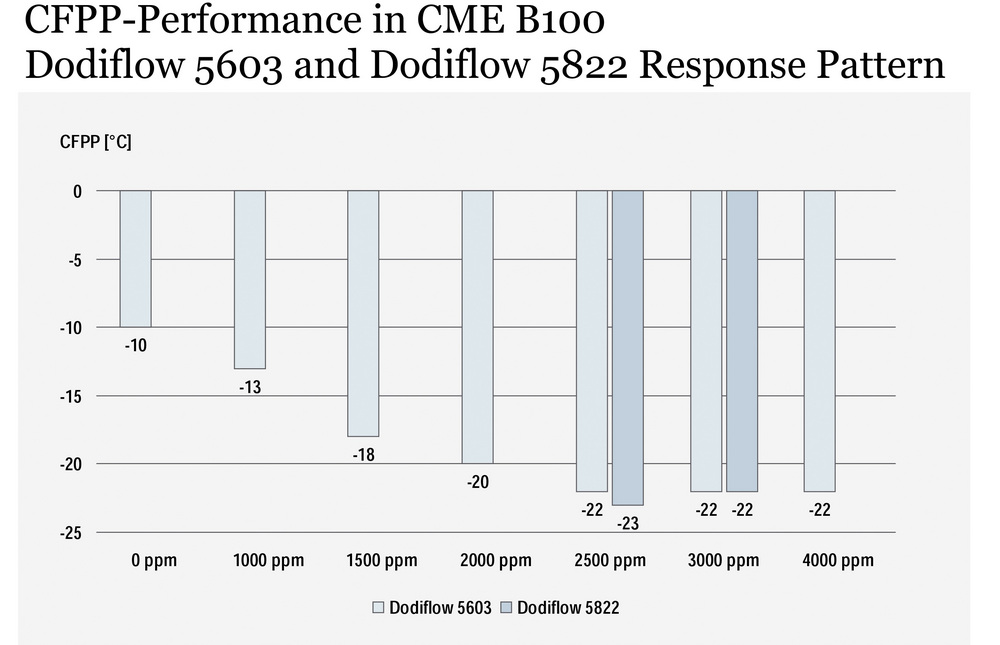

Today very efficient cold flow additive technology is available. This technology allows a lower CFPP and PP for a broad range of first-generation B100. The CFPP response of a flow improver designed for B100 in a 70/30 percent RME/SME mixture, which is now frequently produced in biodiesel blends, is shown in Figure 1.

Due to the higher amounts of saturated fatty acid methyl ester deriving from soy methyl ester, the response for cold flow additives is significantly lowered. Because of this, many flow improvers at high dosage rates will fail to show sufficient reduction in CFPP. With Dodiflow 5603 and Dodiflow 5822, it is still possible to reach the German CFPP winter specification of minus 20 degrees Celsius.

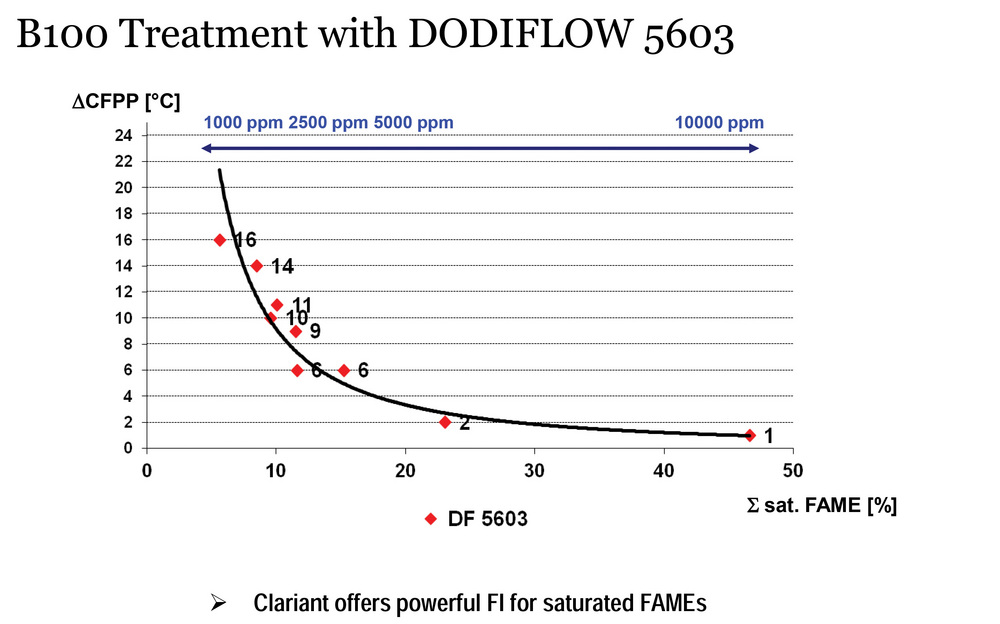

In contrast, PP response of FAME blends typically gives better results and allows handling at much lower temperatures. This is important for refiners who are using this blend component in refinery tank farms and terminals. However, FAME response to cold flow additives is very dependent on the content of saturated fatty acid methyl esters. For CFPP (shown in Figure 2), the results indicate that Dodiflow 5603 does allow a CFPP reduction of 6 C in FAME mixtures with up to around 15 percent saturated FAME.

When the content of total saturates is increased, the CFPP delta goes down and reaches a value of greater than 20 percent. With the additive technology currently used, the FAME virtually gets untreatable at economically reasonable dosage rates.

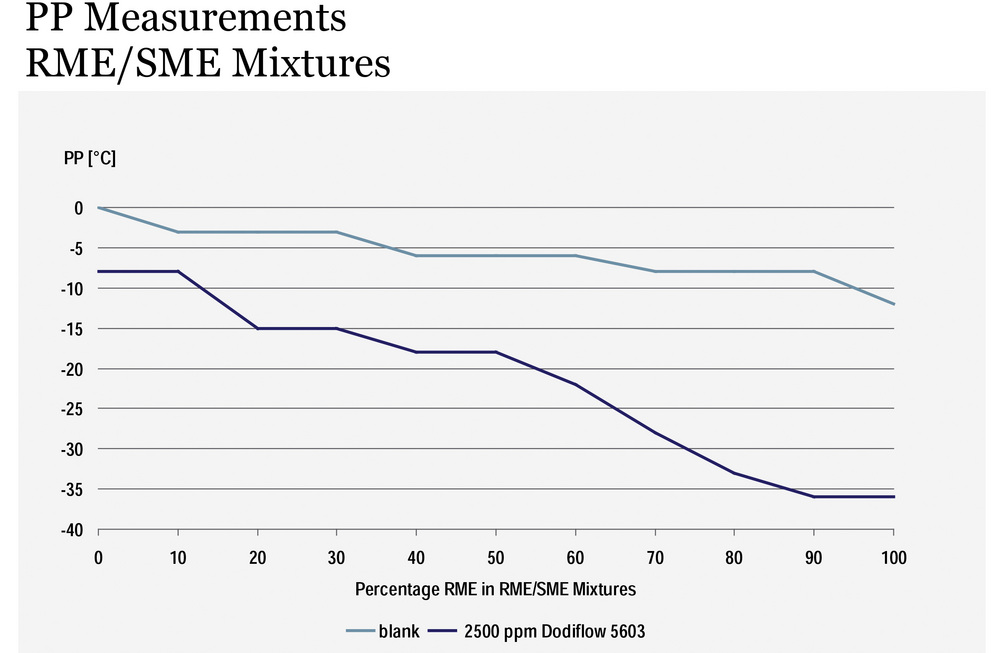

In Figure 3, biodiesel flow improver PP response is shown for RME/SME blends. Large PP deltas achieved start off at low saturates concentrations and decrease as the SME content is increased. The biodiesel CFPP and PP performance is optimized with Dodiflow 5603 because this technology allows the handling of FAME blends with up to 60 percent SME content down to temperatures of minus 18 C. This is especially important regarding handling issues faced by refineries and terminals.

Biodiesel-Mineral Blends

With the introduction of biodiesel quotas, the use of FAME as a diesel blending component is mandatory in Europe. As acknowledged above, FAME has a significant impact on diesel fuel properties such as oxidation stability, lubricity and cetane number. Through the carbon-carbon double bonds unsaturated compounds, the fuel stability is often negatively influenced and has to be compensated by appropriate antioxidants and stabilizers. On the other hand, cetane number and lubricity are positively influenced, which makes additives to bring sulfur-free B0 on-spec obsolete.

Regarding the cold flow additive response, FAME impact can be negative or positive depending on the type and amount of biodiesel used for making the blend. FAME with a low content in saturates, such as RME, typically show higher percentages than what is needed to fulfill the quotas and is indifferent to cold flow additive response.

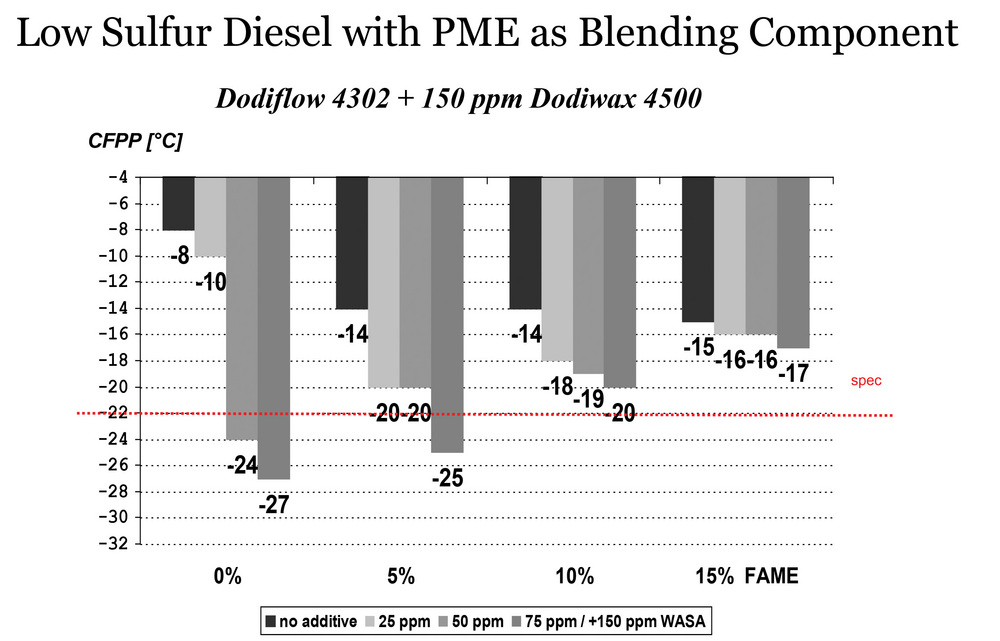

PME, an example of a highly saturated FAME, gives a totally different picture. At low concentrations, nucleating effects dominate the results in a CFPP boost effect, whereas higher blending rates lead to a significant increase in CFPP values (Figure 4).

Often times, the FAME used in the diesel blends is already flow-additized to facilitate handling and pumping at the blending facility. Dodiflow 5603 is successfully used to reduce the PP of this FAME. Compared to conventional diesel, cold flow treatment dosage rates present as rather high. Dodiflow 5603 alleviates these issues, because it is compatible with all conventional cold flow improvers and does not exhibit negative effects when treating the FAME/diesel blend to CFPP specification. Often this Dodiflow-treated FAME helps to lower overall cold flow improver treatment.

Advertisement

Advertisement

Second-Generation Biodiesel

The original concept of “second-generation biodiesel” and its major advantage in terms of sustainability implied the use of a nonalimental feedstock such as biomass from wood and organic waste. The main process postulated involved pyrolysis, creation of synthesis gas and finally liquefaction by Fischer-Tropsch synthesis. The resulting fuels therefore were called biomass to liquid.

Technically, the advantages for use as a fuel compared to first-generation FAME lie in the absence of functional groups and double bonds. These fuels, which are derived from biomass, resemble GTL-fuels derived from natural gas and are regarded as premium in terms of engine compatibility, fuel stability and cetane number.

Alternative fuels of bio-origin (which are hydrocarbon-based) start with vegetable oils and are used as feedstock for first-generation biodiesel. Instead of a transesterification, the triglycerides are directly processed in hydrodesulfurization units (HDS) as neat oil or via cohydrogenation. The resulting fuels are called hydrogenated vegetable oils (HVO).

HVO-Mineral Blends

HVO consists of linear paraffins in a low C-number range with an extremely narrow distribution. The material is wax-like with a solidification point of approximately 30 C.

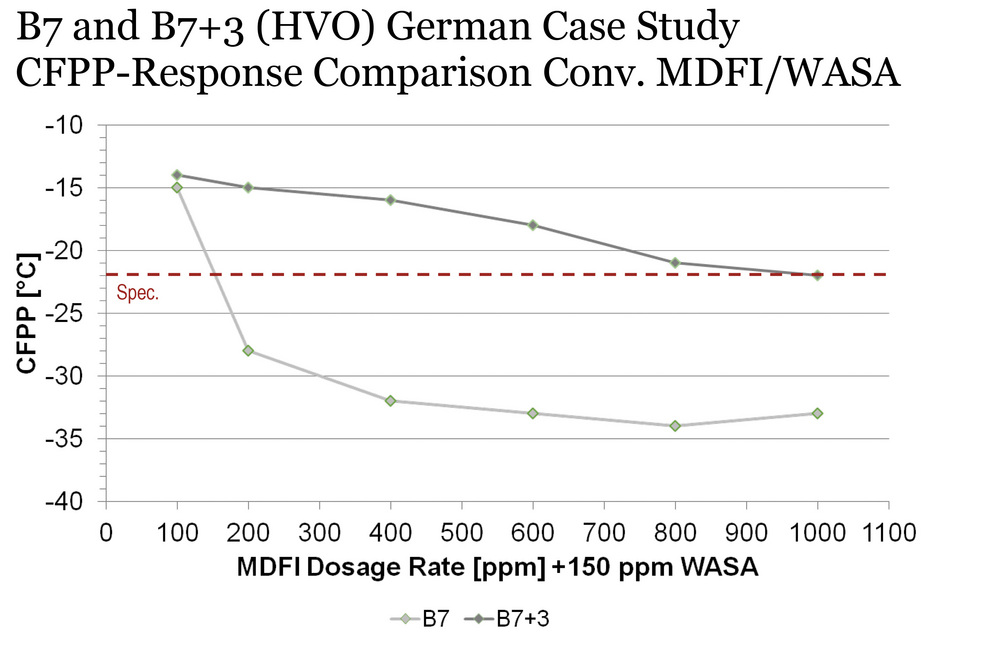

When used as a blending component, this kind of HVO has a devastating effect on the cold flow properties of winterized mineral diesel even at low concentrations. A German case study showed that the addition of 3 percent HVO to a FAME B7 to reach the 10 percent quota target was enough to seriously damage the CFPP performance of the cold flow additives (Figure 5).

Hydro-dewaxed HVO (HDX-HVO) is a much more suitable biofuel. In addition to hydrogenation, the vegetable oil is subject to iso-dewaxing where part of the linear paraffins is transformed or transmuted into iso-paraffins. The materials obtained of these processes are liquids. By controlling the degree of isomerization, CP and PP can be adjusted in a wide range according to the requirements of the application. Nearly all properties of the HVO, including density, oxidation stability and cetane, are maintained.

In terms of CFPP, DWX-HVO fuels such as NExBTL are not critical and can be blended in a wide concentration range into mineral oils. Low CP DWX-HVO can positively influence CFPP response of customized cold flow additives.

Summary

First- and second-generation biodiesels are playing an increasingly important role as blending components in refinery blending operations that must fulfill strict biodiesel quotas. In colder climate areas, appropriate cold flow properties of the resulting blends and the influence of the biodiesel components also have to be considered. With biodiesel flow improvers out of the Dodiflow range, very effective cold flow additives are available. This allows refineries to treat biodiesel blends with a high content of saturated FAME for the desired low CFPP values. It also efficiently reduces pour points, which facilitates easier handling in cold climates.

Authors: Werner A. Reimann, Bettina A. Siggelkow

Senior Expert-Fuels Additives

Global Marketing Manager

Clariant OMS

281-465-9100

+49693055203

Refinery.services@clariant.com

Related Stories

Neste MY Renewable Diesel has helped fuel Rio Tinto’s Pilbara iron ore operations for the first time, with the completion of a successful trial of biofuel across its network of Western Australian ports, railways and mines.

The Singapore Airlines Group has signed a memorandum of understanding (MoU) to potentially source neat SAF from Aether Fuels, a climate technology firm that plans to set up SAF production plants in the U.S. and South East Asia.

To further strengthen their collaboration on reducing emissions in logistics, DHL Group and Neste have agreed to jointly evaluate how Neste’s renewable solutions, such as renewable diesel and SAF, can support DHL in its decarbonization targets.

Avfuel Corp. on Jan. 31 announced it is expanding the availability of sustainable aviation fuel (SAF) by offering the fuel at three additional supply terminals located in Linden, New Jersey; Pasadena, Texas; and Florida’s Port Everglades.

Moeve and Norwegian signed a contract to accelerate the decarbonization of air transport between Spain and the Nordic region by promoting SAF. Moeve produces SAF at its La Rábida Energy Park (Huelva) from used cooking oils.

Upcoming Events