Commercializing Enzymatic Biodiesel Production

PHOTO: VIESEL FUEL LLC

January 3, 2014

BY Rebecca Hobden

Enzyme-catalyzed biodiesel production has long been on the cusp of revolutionizing the way biodiesel is produced. Historically, the high cost of enzymes has outweighed any benefits they might offer, such as their ability to convert low-quality, high free fatty acid (FFA) feedstocks, savings on energy consumption, and coproduction of technical-grade glycerin. Recently, the hurdle of making the process economically viable on a commercial scale has been overcome.

Viesel Fuel LLC, in collaboration with Novozymes and Tactical Fabrication LLC, has developed and implemented a biodiesel production process that uses enzymes to produce at a rate of 5 million gallons annually. Further, this process is easily scalable to larger capacities. Recovery and reuse of the enzymes to catalyze several batches makes the enzymes economically feasible, and simple resin-based technology is used to bring the crude biodiesel into ASTM specifications. Additionally, this process requires a lower capital investment, works at a production cost per gallon that is comparable to that of traditional biodiesel, and most importantly, allows the use of less expensive, more varied feedstocks with free fatty acid content as high as 100 percent.

Feedstocks in the Market

Demand for biodiesel in recent years has greatly increased due to consumer acceptance as well as incentives and mandates, such as the renewable fuel standard (RFS), which are in place through state and federal governments. Consequently, the economic viability of many biodiesel facilities relies heavily on the ever-changing policies related to biodiesel. Because the cost of feedstock is the largest single expenditure in the production of biodiesel, the flexibility enzymes allow to use any feedstock that may appear in the marketplace, from brown grease to virgin oil, is economically advantageous and offers a reprieve for biodiesel producers whose sustainability shifts and destabilizes with the changing value of tax credits and RIN prices.

Pretreatment of feedstock is required to remove impurities that may be harmful to the reaction kinetics (in this case the enzymes) and/or prohibit compliance with ASTM D6751 standards. The use of low-quality feedstocks has been problematic for traditional processes and catalysts, even after all other impurities have been neutralized, due to their high FFA content. A major advantage of enzymes is their ability to easily convert FFA to fatty acid methyl esters (FAME) at temperatures around 95 degrees Fahrenheit, and with less methanol. The appropriate pretreatment method depends on the feedstock, and might include water washes and settling, neutralization of pH, or filtration. Sulfur is one of the more troublesome contaminants in low-quality feedstocks, but research and development of technologies including filtration and resins for sulfur reduction to 15 ppm in either feedstock or crude biodiesel assists in making inexpensive, high-FFA feedstock a viable option.

Advertisement

Enzymatic Reaction

The enzymes are able to convert high-FFA feedstock because the reaction chemistry occurs in two steps: the glycerides are first hydrolyzed to FFA, and then the FFA and methanol are esterified to produce FAME. When using high-FFA feedstock, the hydrolysis step has already occurred and the main job of the enzyme becomes the conversion of FFA to FAME. In the esterification step, water is produced and absorbed into the heavy phase, which also consists of glycerol, excess methanol and enzymes. Conveniently, water is a necessary component to activate the enzymes and does not lead to soapy contaminants, as it does in many traditional processes.

Careful monitoring during the reaction of methanol, water and enzymes in the heavy phase, temperature, and rate of conversion are critical to ensure high-quality finished biodiesel and optimum number of enzyme reuses. The “happier” the enzymes are, the longer they will remain active, and the more economical they become.

Enzyme Recovery and Reuse

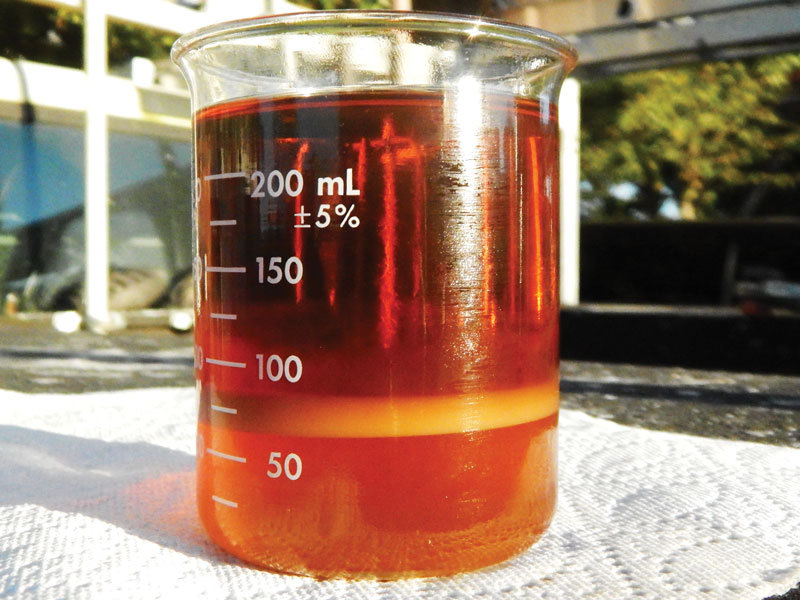

To recover the enzymes, the reaction mixture must go through two different stages of settling. Initial settling results in a heavy phase that includes glycerol, methanol, water and enzymes, as well as a light phase of crude biodiesel. At this point, the crude biodiesel can be withdrawn from the reactor and refined, while the heavy phase requires further separation. The second stage of settling results in a transparent glycerin phase, which falls to the bottom of the reaction vessel, and the enzymes, which migrate to the interface between crude biodiesel and glycerin. This second separation can be expedited by the use of flocculants or mechanically separated with membranes. A portion of the glycerin phase is withdrawn and refined, while the remaining glycerin and the layer of active enzymes are retained in the reactor and reused to catalyze the next reaction. Combining proper feedstock pretreatment and optimized reaction conditions allows Viesel to run a series with a minimum of eight to 10 enzyme reuses, with a 10 percent addition of fresh enzymes to each batch.

Advertisement

The glycerin can be cleaned easily to 80 percent purity with simple vacuum distillation to remove methanol and water. If a processor chooses to add additional processing, such as resins, filtration or active carbon, this glycerin could be purified to greater than 97 percent. In either event, the glycerin can be sold into value-added applications not normally available for crude glycerin.

Biodiesel Refining

The use of enzymes results in a crude biodiesel with 1.5 to 2.0 percent unreacted FFA. Viesel Fuel initially used a caustic wash to turn this FFA to soap, followed by washes and centrifugation to remove the soap and water. The recovered soap was acidulated back to FFA, for reuse as a blend component in the feedstock.

Viesel Fuel has most recently adopted the use of resin technologies, both as a catalyst to convert FFA to FAME and in an ion exchange capacity to adsorb any remaining FFA. The optimization of resins makes the refining process simpler, reduces yield loss, and has allowed Viesel Fuel to transition to a continuous flow process for the biodiesel refining section of the plant. Viesel Fuel will further develop the capability to convert the current batch enzymatic reaction process into a continuous process throughout 2014.

Conclusion

The benefits of enzyme catalysts in the production of biodiesel have long been apparent, but until now their adoption on a commercial scale has not been economically feasible. With production approaching 150 batches in six months, Viesel Fuel’s process has demonstrated that enzymes are an exciting catalyst that require less energy and fewer chemicals. When coupled with resin technologies for refining to ASTM specifications, the process becomes cost comparable to traditional catalysts. But the true economic benefit of enzymes comes in their ability to handle a variety of inexpensive feedstocks, making enzymes a financially prudent route for biodiesel producers, allowing them to thrive despite low RIN prices and the disappearance of tax incentives.

Author: Rebecca Hobden

Chemical Engineer, Viesel Fuel LLC

772-678-9934

rhobden@vieselfuel.com

Related Stories

Biodiesel capacity in the U.S. and Canada dipped slightly stable in 2024, with several renewable diesel producers reporting headwinds and lower margins alongside a drove of SAF projects in various stages of development.

The IEA’s Task 39 group has new research regarding the development and status of the sustainable aviation fuel industry.

The U.S. EPA on Nov. 16 released updated RIN data, reporting that nearly 2.11 billion RINs were generated under the RFS in October, up from 1.81 billion generated during the same month of last year.

Conestoga to host SAFFiRE cellulosic ethanol pilot plant

Conestoga Energy and SAFFiRE Renewables LLC announced on Nov. 16 their agreement for Conestoga to host SAFFiRE’s cellulosic ethanol pilot plant at Conestoga’s Arkalon Energy ethanol facility in Liberal, Kansas.

Officials at Calumet Specialty Products Partners L.P. discussed the company’s proposed plans to boost sustainable aviation fuel (SAF) production at its Montana Renewables biorefinery during third quarter earnings call, held Nov. 9.

Upcoming Events