Constructing a Cleaner Work Environment

September 4, 2007

BY Bryan Sims

Steve Verhey spent much of his childhood on a small farm amid the rolling hills of eastern Washington where the vast, fertile landscape is tranquil and clean. He wants to keep it that way.

While teaching at Central Washington University (CWU), Verhey discovered that renewable energy is a key component to preserving the environment. In 2006, he resigned his teaching post at CWU and used his interests in science and renewable energy to create Central Washington Biodiesel LLC. He is the president and CEO of the 3 MMgy canola oil-based biodiesel plant in Ellensburg, Wash. "It was hard to ignore what was going on in the real world and energy is very important, so I found a way to put those interests together-the interest in biochemistry and energy," Verhey tells Biodiesel Magazine. "I found they're really complementary."

Not long after Verhey produced his first gallon of biodiesel in the fall of 2006, he had an opportunity to get involved in a high-profile construction project in Quincy, Wash., where computer software and media services mogul Microsoft Corp. is building the first of six Windows Live Operations Columbia Data Centers. Turner Construction Co., an international construction contractor, is working on the 500,000-square-foot building, which will serve as the backbone of Microsoft's efforts to compete with other Internet services, such as Google and Yahoo. The project is a physical manifestation of the company's ambition to be the leader in the world of Internet services.

Microsoft was attracted to the Quincy area because of the available space, the access to renewable power and the close proximity to its headquarters in Redmond, Wash, says Microsoft spokesman Lou Gellos. Washington is a hub to some of the cheapest, cleanest electricity in the nation supplied by hydroelectric plants. The first of two phases of the construction project were finished in late 2006. Microsoft expects the data center to be complete sometime in the fall.

As the construction of the project progressed however, concerns over poor air quality and the health of subcontractors working with equipment powered by petroleum-based diesel in an enclosed space became an issue for Turner Construction and RSC Equipment Rental, which supplied some of the equipment for the project.

RSC Equipment Rental Territory Manager Jess Bennett, who is based in Ellensburg, visited Verhey in November 2006 to find out if there were advantages to switching to biodiesel. Verhey used his biodiesel-powered forklift to show Bennett the benefits of bioidesel. Ecstatic about what he saw, Bennett relayed to Turner what he learned about the air quality improvement biodiesel could bring to the construction project. In February, Turner and RSC Equipment Rental approved the transition to B99 and workers have been using it since with no complications. "There were some skeptical contractors but the transition actually was very smooth," Verhey says. The switch was expedited by Bennett and his staff, who checked original equipment manufacturer (OEM) information.

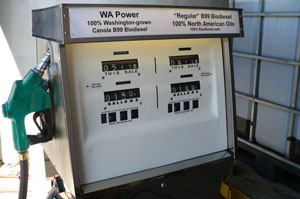

Verhey's company supplied the biodiesel and set up B99 tanks on site. "We went from not even knowing we would be supplying the fuel, to supplying all their fuel needs in a week," Verhey says. The transition from petroleum-based diesel to WA Power (what Verhey has coined his biodiesel) has proven to be hassle-free, environmentally friendly and ultimately a relief for the workers who are now exposed to healthier working conditions.

A Smooth Transition

Early resistance to biodiesel was minimized because RSC Equipment Rental approved B99 for use in all of its diesel-powered equipment. "We were actually surprised at how little trouble there was," Bennett says. "This was a fairly high-stakes situation. If anything bad had happened that would've set things back, but we were lucky enough that everything went well." In fact, the switch to biodiesel was so transparent that when the state Department of Labor and Industries came to the site to check the air quality, the inspectors thought that their instruments were malfunctioning, Verhey says. "The majority of the time it seems like the guys just suffered through it," Bennett says. "I just can't imagine what the jobs have been like in the past [using petroleum-based diesel] in an enclosed situation and having to do the things you need to do."

During Verhey and Turner's first meeting, the construction company decided to totally change over to B99 for the project. According to Verhey, seven cement trucks were working 12-hour days, six days a week for a while, running on biodiesel until the floor of the massive building was complete. All in all, the transition went smoothly, Bennett says. "We expected more [problems] and we were prepared for more but there actually haven't been any problems whatsoever," he says.

Forklifts, backhoes, trackhoes, front-end loaders and dump trucks were the majority of equipment that began using B99 fuel during the first phase of construction. Now, with phase two of the project currently in progress, the biofuel is stored inside of the building in totes where it's easily accessible and portable for the workers. Also on the site are two 33,000 gallon tanks of petrodiesel to power generators for backup power. Those tanks were full of fuel when Verhey met with the construction crew and he was cautious about filling them with biodiesel because it has a shorter shelf life compared with petroleum-based diesel.

Canola-based biodiesel's excellent winter properties allowed Turner Construction and RSC Equipment Rental to use B99 during the winter, according to Verhey. Biodiesel made with canola oil performs effectively at or near 20 degrees Fahrenheit.

Starting a Trend

Although biodiesel had never been used on a construction site in the state of Washington, Bennett believes that in doing so other construction and equipment rental companies will follow suit because of its environmental and health benefits. However, before others dive into using biofuels education is paramount. "I don't know that other people feel as comfortable or are well-informed enough to do it," Bennett says. "With the reservations that the majority of the other equipment suppliers had, I think people need to be more educated about it and realize just how good biodiesel is for the equipment and the people."

Microsoft's efforts to include environmentally friendly features in its data center structures don't stop at using biofuels during the construction phase. The data center in Quincy is designed to have a minimal to no carbon footprint, according to a Microsoft spokesman. The company's greening efforts include retrofitting existing data centers to decrease the amount of power used to cool the racks of servers, allowing the buildings to capture outside air, maximizing the use of green building technology detailed by the Leadership in Energy and Environmental Design (LEED) Green Building Rating System, a voluntary, concensus-based national standard for developing high-performance and sustainable buildings. Yahoo and Google are looking to follow suit with their data centers.

Verhey would like to see government entities at the state and federal levels require contractors to use biodiesel in their equipment. The move would alleviate the potential for hazardous material spills and other effluent discharge associated with using regular petroleum-based diesel. "The guys working in [the data center] like using [biodiesel]," Verhey says. "They really appreciated that Turner and RSC Rentals were trying to do something to help them because it's nasty to work in a place like that with diesel. They appreciated the better working conditions in general."

Bryan Sims is a Biodiesel Magazine staff writer. Reach him at bsims@bbibiofuels.com or (701) 746-8385.

While teaching at Central Washington University (CWU), Verhey discovered that renewable energy is a key component to preserving the environment. In 2006, he resigned his teaching post at CWU and used his interests in science and renewable energy to create Central Washington Biodiesel LLC. He is the president and CEO of the 3 MMgy canola oil-based biodiesel plant in Ellensburg, Wash. "It was hard to ignore what was going on in the real world and energy is very important, so I found a way to put those interests together-the interest in biochemistry and energy," Verhey tells Biodiesel Magazine. "I found they're really complementary."

Not long after Verhey produced his first gallon of biodiesel in the fall of 2006, he had an opportunity to get involved in a high-profile construction project in Quincy, Wash., where computer software and media services mogul Microsoft Corp. is building the first of six Windows Live Operations Columbia Data Centers. Turner Construction Co., an international construction contractor, is working on the 500,000-square-foot building, which will serve as the backbone of Microsoft's efforts to compete with other Internet services, such as Google and Yahoo. The project is a physical manifestation of the company's ambition to be the leader in the world of Internet services.

Microsoft was attracted to the Quincy area because of the available space, the access to renewable power and the close proximity to its headquarters in Redmond, Wash, says Microsoft spokesman Lou Gellos. Washington is a hub to some of the cheapest, cleanest electricity in the nation supplied by hydroelectric plants. The first of two phases of the construction project were finished in late 2006. Microsoft expects the data center to be complete sometime in the fall.

As the construction of the project progressed however, concerns over poor air quality and the health of subcontractors working with equipment powered by petroleum-based diesel in an enclosed space became an issue for Turner Construction and RSC Equipment Rental, which supplied some of the equipment for the project.

RSC Equipment Rental Territory Manager Jess Bennett, who is based in Ellensburg, visited Verhey in November 2006 to find out if there were advantages to switching to biodiesel. Verhey used his biodiesel-powered forklift to show Bennett the benefits of bioidesel. Ecstatic about what he saw, Bennett relayed to Turner what he learned about the air quality improvement biodiesel could bring to the construction project. In February, Turner and RSC Equipment Rental approved the transition to B99 and workers have been using it since with no complications. "There were some skeptical contractors but the transition actually was very smooth," Verhey says. The switch was expedited by Bennett and his staff, who checked original equipment manufacturer (OEM) information.

Verhey's company supplied the biodiesel and set up B99 tanks on site. "We went from not even knowing we would be supplying the fuel, to supplying all their fuel needs in a week," Verhey says. The transition from petroleum-based diesel to WA Power (what Verhey has coined his biodiesel) has proven to be hassle-free, environmentally friendly and ultimately a relief for the workers who are now exposed to healthier working conditions.

A Smooth Transition

Early resistance to biodiesel was minimized because RSC Equipment Rental approved B99 for use in all of its diesel-powered equipment. "We were actually surprised at how little trouble there was," Bennett says. "This was a fairly high-stakes situation. If anything bad had happened that would've set things back, but we were lucky enough that everything went well." In fact, the switch to biodiesel was so transparent that when the state Department of Labor and Industries came to the site to check the air quality, the inspectors thought that their instruments were malfunctioning, Verhey says. "The majority of the time it seems like the guys just suffered through it," Bennett says. "I just can't imagine what the jobs have been like in the past [using petroleum-based diesel] in an enclosed situation and having to do the things you need to do."

During Verhey and Turner's first meeting, the construction company decided to totally change over to B99 for the project. According to Verhey, seven cement trucks were working 12-hour days, six days a week for a while, running on biodiesel until the floor of the massive building was complete. All in all, the transition went smoothly, Bennett says. "We expected more [problems] and we were prepared for more but there actually haven't been any problems whatsoever," he says.

Forklifts, backhoes, trackhoes, front-end loaders and dump trucks were the majority of equipment that began using B99 fuel during the first phase of construction. Now, with phase two of the project currently in progress, the biofuel is stored inside of the building in totes where it's easily accessible and portable for the workers. Also on the site are two 33,000 gallon tanks of petrodiesel to power generators for backup power. Those tanks were full of fuel when Verhey met with the construction crew and he was cautious about filling them with biodiesel because it has a shorter shelf life compared with petroleum-based diesel.

Canola-based biodiesel's excellent winter properties allowed Turner Construction and RSC Equipment Rental to use B99 during the winter, according to Verhey. Biodiesel made with canola oil performs effectively at or near 20 degrees Fahrenheit.

Starting a Trend

Although biodiesel had never been used on a construction site in the state of Washington, Bennett believes that in doing so other construction and equipment rental companies will follow suit because of its environmental and health benefits. However, before others dive into using biofuels education is paramount. "I don't know that other people feel as comfortable or are well-informed enough to do it," Bennett says. "With the reservations that the majority of the other equipment suppliers had, I think people need to be more educated about it and realize just how good biodiesel is for the equipment and the people."

Microsoft's efforts to include environmentally friendly features in its data center structures don't stop at using biofuels during the construction phase. The data center in Quincy is designed to have a minimal to no carbon footprint, according to a Microsoft spokesman. The company's greening efforts include retrofitting existing data centers to decrease the amount of power used to cool the racks of servers, allowing the buildings to capture outside air, maximizing the use of green building technology detailed by the Leadership in Energy and Environmental Design (LEED) Green Building Rating System, a voluntary, concensus-based national standard for developing high-performance and sustainable buildings. Yahoo and Google are looking to follow suit with their data centers.

Verhey would like to see government entities at the state and federal levels require contractors to use biodiesel in their equipment. The move would alleviate the potential for hazardous material spills and other effluent discharge associated with using regular petroleum-based diesel. "The guys working in [the data center] like using [biodiesel]," Verhey says. "They really appreciated that Turner and RSC Rentals were trying to do something to help them because it's nasty to work in a place like that with diesel. They appreciated the better working conditions in general."

Bryan Sims is a Biodiesel Magazine staff writer. Reach him at bsims@bbibiofuels.com or (701) 746-8385.

Advertisement

Advertisement

Upcoming Events