Enogen corn, ICM technologies add value at Minnesota plant

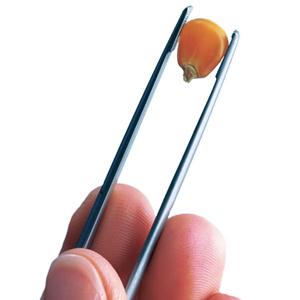

PHOTO: Syngenta

November 28, 2018

BY Syngenta

A recent trial evaluating the use of Enogen corn enzyme technology with ICM’s Selective Milling Technology and Fiber Separation Technology successfully demonstrated that the technologies work well together, providing synergies that can bring higher ethanol yield and more robust starch-fiber separations. The technologies were tested at Corn Plus, a Minnesota-based dry grind ethanol plant.

Enogen corn is an in-seed innovation available exclusively from Syngenta and features the first biotech corn output trait designed specifically to enhance ethanol production. Using modern biotechnology to deliver best-in-class alpha amylase enzyme directly in grain, Enogen corn eliminates the need to add liquid alpha amylase. The product is rapidly gaining widespread acceptance because of the value it delivers to ethanol producers and the opportunity it provides corn growers to be enzyme suppliers for their local ethanol plants.

Advertisement

Advertisement

“Enogen grain works across a broad range of pH and temperatures, facilitating an unparalleled break in viscosity through unique enzyme activity and unmatched dosage rates,” said Dr. Miloud Araba, head of technical services for Enogen at Syngenta. “Breakthroughs in viscosity reduction can lead to unprecedented levels of solids loading, which directly contribute to increased throughput and yield, as well as significant cost savings from reduced natural gas, electricity and water use.”

“SMT and FST are two of ICM’s value-added, patented technology platforms,” said Steve Hartig, ICM vice president of technology development. “Both technologies are designed to help maximize production and minimize operational expense. SMT maximizes the amount of starch exposed for conversion to ethanol and oil available for recovery while preserving fiber for higher value platform applications. FST is a progressive pre-fermentation system that removes fiber prior to fermentation, allowing more fermentable carbohydrates to be loaded into each batch for fermentation.”

Advertisement

Advertisement

“Using Enogen corn, with its mode of action and high amount of expressed enzyme, brings a lower viscosity to the corn mash. The lower viscosity provides improved separation capability, leading to increased efficiencies when working in tandem with the SMT and FST systems,” Hartig added.

Related Stories

The U.S Department of Energy Bioenergy Technologies Office, in partnership with the Algae Foundation and NREL, on July 21 announced the grand champion and top four winning teams of the 2023 - 2025 U.S. DOE AlgaePrize Competition.

The European Commission on July 18 announced its investigation into biodiesel imports from China is now complete and did not confirm the existence of fraud. The commission will take action, however, to address some systemic weaknesses it identified.

Kintetsu World Express Inc. has signed an additional agreement with Hong Kong, China-based Cathay Pacific Airways for the use of sustainable aviation fuel (SAF). The agreement expands a three-year partnership between the two companies.

Broco Energy on July 17 announced a new partnership with the Massachusetts Port Authority (Massport) to deliver and transition Massport's fuel tanks to renewable diesel across its various facilities.

Shell Aviation, Accenture, and Amex GBT on July 10 announced Avelia is in the process of evolving to an industry solution with independent data hosting and a multi-supplier model helping users access the GHG benefits of SAF.

Upcoming Events