How Pellets Compare to Fossil Fuels in Carbon Intensity and Cost

September 12, 2014

BY Puneet Dwivedi

Biomass-based electricity generation could help in reducing carbon emissions from the U.S. electricity sector, which currently emits about 35 percent of total carbon emissions nationally. The use of wood pellets instead of coal and natural gas would help in reducing carbon emissions of the electricity sector in the United States. However, special policy incentives in the form of direct subsidies, carbon tax and carbon markets will be needed to promote use of wood pellets as a potential feedstock for electricity generation in the United States, in general, and the South, in particular.

There are 128 biomass-based power plants across 27 states with a combined capacity of 3,269 MW. The majority rely upon tree bark, low-quality wood chips and waste paper for electricity generation; none are utilizing wood pellets. This is unanticipated, especially when the U.S. is a leading exporter of wood pellets to Europe, where electric utilities are working to meet the EU goal of sourcing 20 percent of total energy from renewable sources by the end of 2020. To understand why the U.S. is so different from Europe, we need to understand the potential carbon benefit and unit cost of electricity generated from wood pellets in the U.S. compared to coal and natural gas.

Carbon and Cost

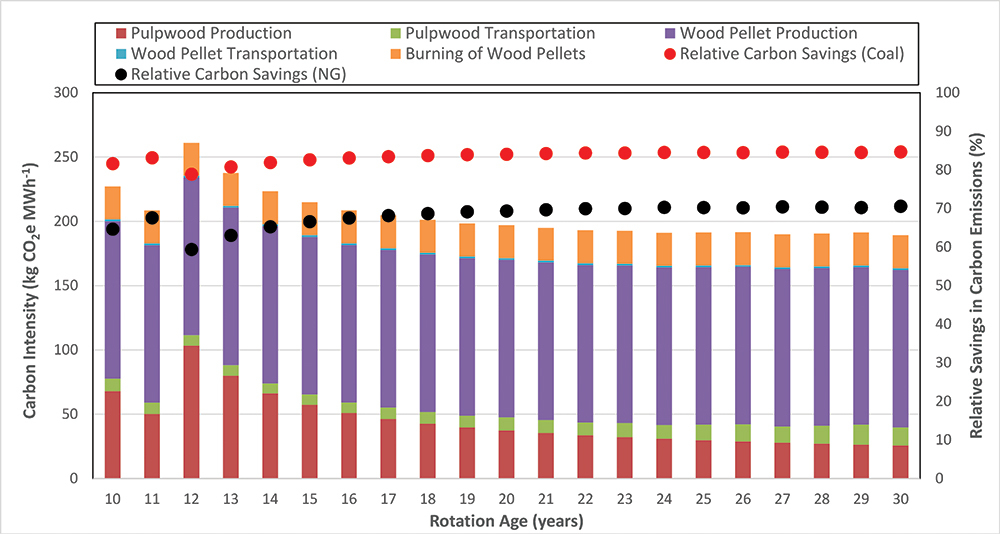

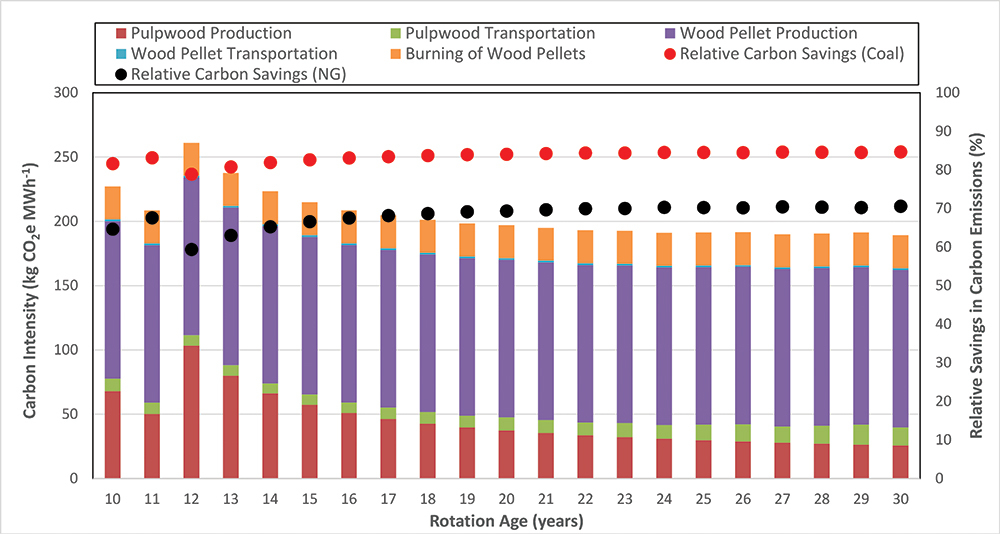

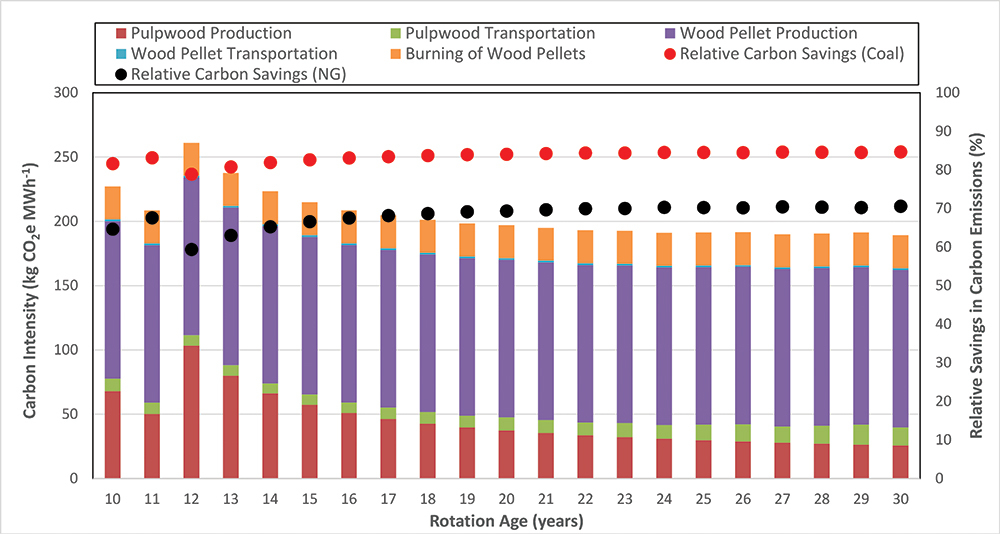

As shown in the chart, the carbon intensity of a unit of electricity consumed within the U.S. ranges from a carbon dioxide equivalent (CO2e) of 189 to 261 kilograms (kg) CO2e/megawatt hour (MWh), depending upon the rotation age of the loblolly pine plantation providing the pellet feedstock. An increase at the rotation age of 12 years was due to the use of fertilizers. Pellet manufacturing contributed the most to the carbon intensity of generated electricity, followed by pulpwood production at about 21 percent across rotation ages. The burning of wood pellets at the power plant contributed about 12 percent towards overall carbon intensity. Emissions related to pulpwood transportation to a wood pellet plant increased with a rise in rotation age since pulpwood availability typically goes down.

Relative carbon savings from pellet-derived electricity ranged from 79 to 85 percent compared to coal power and 59 to 70 percent compared to natural gas. Across rotation ages, relative savings from pellet-derived were 83 percent and 68 percent, compared to coal and natural gas respectively.

The cost of a unit of electricity consumed within the U.S. ranged between $171 and $175.40 per MWh, depending upon the pine rotation age. The cost of pulpwood procurement (stumpage, logging, and pulpwood transportation) was about 26 percent of the overall cost across rotation ages. Manufacturing of wood pellets and generation of electricity at the power plant contributed about 30 and 40 percent, respectively, toward the overall cost of a unit of electricity across rotation ages. The average unit cost was $173 per MWh, which was 73 percent and 157 percent higher than the average obtained from coal, at $100 per MWh, and natural gas, at $67 per MWh, respectively.

This cost differential is the main reason U.S. electric utilities show little interest in utilizing wood pellets. Therefore, special policy incentives will be needed to promote wood pellets as a potential feedstock, instead of coal and natural gas.

Policy Alternatives

The first policy approach could be to provide direct subsidies to those electric utilities interested in generating electricity from wood pellets. A minimum payment of $73 per MWh of consumed electricity will likely be needed to promote wood pellets, instead of coal. To replace natural gas with wood pellets, however, a minimum subsidy level of $106 per MWh of consumed electricity will be needed.

The second approach could be to tax carbon emitted while producing electricity from coal and natural gas. In this case, a minimum carbon tax of $70 per metric ton CO2e will be needed for coal and a minimum carbon tax of at least $235 per metric ton CO2e for natural gas.

A third option could be to establish carbon markets at the national or regional levels. The carbon prices should be reasonably close to $73 per metric ton CO2e or higher to compensate electric utilities utilizing wood pellets.

Enacting these incentives would be quite challenging, considering the current state of debate on reducing carbon emissions in the United States at the federal and state levels, amalgamated with the recovering economy. Recently proposed carbon pollution standards by the U.S. EPA could help in promoting wood pellets as a potential feedstock, especially in those states that do not have sufficient forestry resources. Carbon pollution standards are still evolving, however, and the agency is currently deliberating key components of proposed carbon standards with several stakeholders. Nevertheless, the use of wood pellets as a potential feedstock for electricity generation will face a stiff competition from natural gas in coming years, as abundant quantities of natural gas are available at relatively cheaper rates for a foreseeable future.

Author: Puneet Dwivedi

Assistant Professor, Sustainability Sciences

Warnell School of Forestry and Natural

Resources, University of Georgia

706-542-2406

puneetd@uga.edu

-------------------

Advertisement

The claims and statements made in this article belong exclusively to the author(s) and do not necessarily refl ect the views of Pellet Mill Magazine or its advertisers. All questions pertaining to this article should be directed to the author(s).

Advertisement

Upcoming Events