If You Build it …

September 8, 2008

BY Suzanne H. Schmidt

Being situated in the heart of the U.S. corn and ethanol production region has its advantages. The communities of Blair, Neb., and Cedar Rapids, Iowa, have attracted the attention of two of the world leaders in enzyme production. Novozymes chose Nebraska for its newest production site and Genencor, a division of Danisco, is expanding its educational base in Iowa with the building of an Applications and Training Center of Excellence. These companies are producing easily assessable products for their customers in the Midwest and North America. While each company's focus is unique, both are important for the future of ethanol production.

Novozymes' decision to build a facility in the Midwest was based on several factors, first and foremost being logistics. Railways and main roads are in close proximity to its building site in Blair. Transportation costs vary by shipping location, "but it's one of the key reasons we chose to put our next factory in the Midwest, to minimize transportation costs," says Poul. Ruben Andersen, global director of biofuels for Novozymes. The market for this facility will generally be focused on North American ethanol producers, "but we do export enzymes across the world," Andersen adds.

The enzymes used to produce fuel ethanol are usually shipped in liquid form, which is the cheapest and simplest option. Once produced, the liquid enzymes are loaded into trucks and tankers. These loads can weigh up to 20 tons and are generally moved by trains or trucks. The enzymes can be sent by airplane, but typically aren't because of the cost.

The enzymes need to be handled properly as they generally have a year shelf life at room temperature "Enzymes are biological, just like milk or beer or any other biological material," Andersen says. Depending on the preparation of the enzymes, some must be kept at about 41 degrees Fahrenheit.

Novozymes also had to consider the terrain, water supply, travel routes and what it would do with the effluent stream, which must be purified by biological rinsing to break down the remaining nutrients in the process wastewater, Andersen says. "The end product of the effluent stream is a fertilizer that's used in fields in the United States, Denmark and China," he says. Although the exact method of distributing the waste product is still being determined for the Nebraska site, Andersen expects it will be a pipeline system. "We have a pipeline in at our Denmark facility and at our enzyme facility in North Carolina," Andersen explains.

Novozymes searched the globe for an ideal location for its newest plant before settling on Blair, a community of about 7,512 residents. The enzyme company considered South America and China for a production site before deciding to build in the United States, where a majority of its customer base is located. But then there was the question of where to build in the United States. "We were looking in the Corn Belt states," says Peder Holk Nielson, executive vice president and head of Novozymes business.

Novozymes found that Nebraska has the resources it needs. "Energy at the right price was essential and incentives by the state had a role to play here too," Nielson says. The community has also shown support for the project. "We approved $800,000 of our economic development funds to help Novozymes make the decision to locate here, so from a community standpoint we have been very positive and very supportive of the whole industry," says Rodney Storm, Blair city administrator. The facility has the potential to be an economic boom for the community. "The impact on Blair will be significant as an investment in job creation, and it puts us in a better position to be more competitive in global energy projects," says Richard Baier, the director of the Nebraska Department of Economic Development. "We were able to secure a site for [Novozymes] adjacent to the Blair Biorefinery Campus, and it's a good fit." Although Blair is a small community, it is about 25 miles from the Omaha metropolitan area, which will help meet the need for high-tech workers. Beyond these benefits, Novozymes has a relationship with Cargill Inc.'s ethanol plant in Blair. "I think that the state put together a great incentive package and we showed them we sure wanted them here in Nebraska," Baier adds.

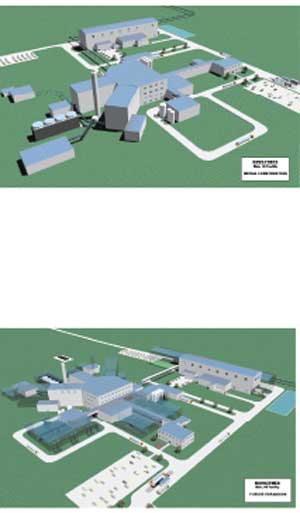

The enzyme production facility will be built on 30 acres of Nebraska plains. The new facility will cost $80 million to $100 million dollars. Novozymes expects to break ground in late 2008 and have enzymes ready for use in 2010.

The facility will initially focus on supplying enzymes for the corn-based ethanol industry and for cellulosic ethanol start-ups. The main concern now is whether the cellulosic ethanol demonstration plants will be ready for those enzymes in 2010. "It may be more like 2011, but we will be supplying these demonstration plants," Nielson says. "This new plant will have the infrastructure to continue growing the cellulosic ethanol enzymes business into the next decade." The facility is specially designed and can adapt to changes in science and technology. "The way we look at it is initially we can bridge over into Blair with our plant and depending how the technologies pan out we can build many different kinds of technologies in the 2011 to 2012 timeline," Nielson says.

Novozymes says its investment in the Midwest is not just about producing a product, it's a commitment to the people, the industry and the area. "In more regional terms, we will also want to be a part of creating jobs in ethanol," Nielson says. Novozymes initially expects to hire 100 employees.

The Novozymes enzyme production facility brings a technological edge to Blair. "I think it's a wonderful example of how you may think it's a little area, but next thing you know, they have a high tech company moving in and it actually is a very competitive area," Nielson says.

The size of the facility and the investment leave no doubt about Novozymes' commitment to the ethanol industry and its North American customers. "We do this as a long-term investment," Nielsen says. "This plant will sit there for the next 50 years, so take this as a commitment to a long-term development of bioenergy and biofuels in the Midwest."

Tip-Top Training in Cedar Rapids

Novozymes is not the lone enzyme producer moving to the Midwest. Genencor is expanding its facilities, but it is taking the educational route by building a 20,000-square-foot Applications and Training Center of Excellence. Genencor recently broke ground on its $4.6 million facility in Cedar Rapids, which will provide state-of-the-art training for ethanol producers and carbohydrate processing customers. The facility is expected to be complete by the spring of 2009.

"Genencor has been focused on meeting the needs of the grain processing enzyme market since its inception," says Troy Wilson, vice president and business unit manager of Genencor's global grain processing business unit. "That led us to locate our principal manufacturing and applications laboratories in the Midwest beginning in the 1980s. In the past five years, we've invested over $50 million in capacity expansions to keep pace with the rapid expansion of the fuel ethanol industry, building the Center of Excellence is the natural next step."

The Center of Excellence enhances Genencor's service to its customers who produce fuel alcohol and sweeteners. The training center will consist of "a laboratory, pilot plant, training classrooms and additional office space," Wilson says. "It will house the applications development and technical service team." Nearly 20 experts will be on hand to provide assistance to customers.

The facility will have two main sections for applications development and technical service. Applications development uses innovation to meet customers' needs. Technical service addresses specific customer questions. Some questions that will be addressed at the education center are to determine the phytate content in distillers dried grains with solubles and how fermentor solids correlate with yield. "Our customers look to us to answer questions about alternative feedstocks," Wilson says. "The facility will allow us to collaborate in

answering these questions. It will also enable customers to continue their professional development."

The training center will be available for ethanol plant staff to receive extensive instruction. "We will conduct initial and ongoing training sessions for plant personnel including operators, lab personnel and management," Wilson says. This will combine classroom presentations with hands-on work in the applications and analytical laboratories."

The ethanol industry has faced some challenges in the form of high feedstock costs and criticism from the media regarding the use of food to produce fuel. Both companies say that despite these challenges, they are committed to their customers and developments in the Midwest.

The enzyme maker is also a welcome addition to the Cedar Rapids community. "Genencor's decision to locate its new Center of Excellence in Cedar Rapids is a clear sign that we have made some good decisions in the growth and development of our community," Cedar Rapids Mayor Kay Halloran said in a press release. "Genencor has been a part of that growth and development, by providing highly skilled jobs to our residents and serving as a community leader. We are very excited to see Genencor continue to grow in Cedar Rapids."

Novozymes' decision to build a facility in the Midwest was based on several factors, first and foremost being logistics. Railways and main roads are in close proximity to its building site in Blair. Transportation costs vary by shipping location, "but it's one of the key reasons we chose to put our next factory in the Midwest, to minimize transportation costs," says Poul. Ruben Andersen, global director of biofuels for Novozymes. The market for this facility will generally be focused on North American ethanol producers, "but we do export enzymes across the world," Andersen adds.

The enzymes used to produce fuel ethanol are usually shipped in liquid form, which is the cheapest and simplest option. Once produced, the liquid enzymes are loaded into trucks and tankers. These loads can weigh up to 20 tons and are generally moved by trains or trucks. The enzymes can be sent by airplane, but typically aren't because of the cost.

The enzymes need to be handled properly as they generally have a year shelf life at room temperature "Enzymes are biological, just like milk or beer or any other biological material," Andersen says. Depending on the preparation of the enzymes, some must be kept at about 41 degrees Fahrenheit.

Novozymes also had to consider the terrain, water supply, travel routes and what it would do with the effluent stream, which must be purified by biological rinsing to break down the remaining nutrients in the process wastewater, Andersen says. "The end product of the effluent stream is a fertilizer that's used in fields in the United States, Denmark and China," he says. Although the exact method of distributing the waste product is still being determined for the Nebraska site, Andersen expects it will be a pipeline system. "We have a pipeline in at our Denmark facility and at our enzyme facility in North Carolina," Andersen explains.

Novozymes searched the globe for an ideal location for its newest plant before settling on Blair, a community of about 7,512 residents. The enzyme company considered South America and China for a production site before deciding to build in the United States, where a majority of its customer base is located. But then there was the question of where to build in the United States. "We were looking in the Corn Belt states," says Peder Holk Nielson, executive vice president and head of Novozymes business.

Novozymes found that Nebraska has the resources it needs. "Energy at the right price was essential and incentives by the state had a role to play here too," Nielson says. The community has also shown support for the project. "We approved $800,000 of our economic development funds to help Novozymes make the decision to locate here, so from a community standpoint we have been very positive and very supportive of the whole industry," says Rodney Storm, Blair city administrator. The facility has the potential to be an economic boom for the community. "The impact on Blair will be significant as an investment in job creation, and it puts us in a better position to be more competitive in global energy projects," says Richard Baier, the director of the Nebraska Department of Economic Development. "We were able to secure a site for [Novozymes] adjacent to the Blair Biorefinery Campus, and it's a good fit." Although Blair is a small community, it is about 25 miles from the Omaha metropolitan area, which will help meet the need for high-tech workers. Beyond these benefits, Novozymes has a relationship with Cargill Inc.'s ethanol plant in Blair. "I think that the state put together a great incentive package and we showed them we sure wanted them here in Nebraska," Baier adds.

The enzyme production facility will be built on 30 acres of Nebraska plains. The new facility will cost $80 million to $100 million dollars. Novozymes expects to break ground in late 2008 and have enzymes ready for use in 2010.

The facility will initially focus on supplying enzymes for the corn-based ethanol industry and for cellulosic ethanol start-ups. The main concern now is whether the cellulosic ethanol demonstration plants will be ready for those enzymes in 2010. "It may be more like 2011, but we will be supplying these demonstration plants," Nielson says. "This new plant will have the infrastructure to continue growing the cellulosic ethanol enzymes business into the next decade." The facility is specially designed and can adapt to changes in science and technology. "The way we look at it is initially we can bridge over into Blair with our plant and depending how the technologies pan out we can build many different kinds of technologies in the 2011 to 2012 timeline," Nielson says.

Novozymes says its investment in the Midwest is not just about producing a product, it's a commitment to the people, the industry and the area. "In more regional terms, we will also want to be a part of creating jobs in ethanol," Nielson says. Novozymes initially expects to hire 100 employees.

The Novozymes enzyme production facility brings a technological edge to Blair. "I think it's a wonderful example of how you may think it's a little area, but next thing you know, they have a high tech company moving in and it actually is a very competitive area," Nielson says.

The size of the facility and the investment leave no doubt about Novozymes' commitment to the ethanol industry and its North American customers. "We do this as a long-term investment," Nielsen says. "This plant will sit there for the next 50 years, so take this as a commitment to a long-term development of bioenergy and biofuels in the Midwest."

Tip-Top Training in Cedar Rapids

Novozymes is not the lone enzyme producer moving to the Midwest. Genencor is expanding its facilities, but it is taking the educational route by building a 20,000-square-foot Applications and Training Center of Excellence. Genencor recently broke ground on its $4.6 million facility in Cedar Rapids, which will provide state-of-the-art training for ethanol producers and carbohydrate processing customers. The facility is expected to be complete by the spring of 2009.

"Genencor has been focused on meeting the needs of the grain processing enzyme market since its inception," says Troy Wilson, vice president and business unit manager of Genencor's global grain processing business unit. "That led us to locate our principal manufacturing and applications laboratories in the Midwest beginning in the 1980s. In the past five years, we've invested over $50 million in capacity expansions to keep pace with the rapid expansion of the fuel ethanol industry, building the Center of Excellence is the natural next step."

The Center of Excellence enhances Genencor's service to its customers who produce fuel alcohol and sweeteners. The training center will consist of "a laboratory, pilot plant, training classrooms and additional office space," Wilson says. "It will house the applications development and technical service team." Nearly 20 experts will be on hand to provide assistance to customers.

The facility will have two main sections for applications development and technical service. Applications development uses innovation to meet customers' needs. Technical service addresses specific customer questions. Some questions that will be addressed at the education center are to determine the phytate content in distillers dried grains with solubles and how fermentor solids correlate with yield. "Our customers look to us to answer questions about alternative feedstocks," Wilson says. "The facility will allow us to collaborate in

answering these questions. It will also enable customers to continue their professional development."

The training center will be available for ethanol plant staff to receive extensive instruction. "We will conduct initial and ongoing training sessions for plant personnel including operators, lab personnel and management," Wilson says. This will combine classroom presentations with hands-on work in the applications and analytical laboratories."

The ethanol industry has faced some challenges in the form of high feedstock costs and criticism from the media regarding the use of food to produce fuel. Both companies say that despite these challenges, they are committed to their customers and developments in the Midwest.

The enzyme maker is also a welcome addition to the Cedar Rapids community. "Genencor's decision to locate its new Center of Excellence in Cedar Rapids is a clear sign that we have made some good decisions in the growth and development of our community," Cedar Rapids Mayor Kay Halloran said in a press release. "Genencor has been a part of that growth and development, by providing highly skilled jobs to our residents and serving as a community leader. We are very excited to see Genencor continue to grow in Cedar Rapids."

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events