Round Robins Give Lab Managers Feedback on Test Methods

PHOTO: SUSANNE RETKA SCHILL, BBI INTERNATIONAL

December 19, 2013

BY Wayne Mattsfield

Quality assurance (QA) programs in the internal, on-site laboratories at fuel ethanol plants are the primary and most immediate feedback for monitoring plant efficiencies and internal QA practices. In the course of working with clients, questions have been posed regarding the accuracy and precision of the procedures and results generated by the laboratories. Not only do individual plants want to ensure their own results are accurate, but there is also interest in being able to benchmark lab results against those from other laboratories. With this in mind, Phibro Ethanol Performance Group offers a round robin program for interested customers to allow them to anonymously monitor the quality of their own results while benchmarking those results against others.

In the laboratory round robin program, a pretested control sample of known composition is prepared and sent to a group of participating laboratories to use in conducting their standard series of analytical tests. Client laboratories are sent a sample containing the typical sugars, acids, glycerol and ethanol components routinely analyzed by HPLC (high performance liquid chromatography). The HPLC instrument separates, identifies and quantifies the components of interest from a sample in most fuel ethanol plant laboratories.

In the first two round robins organized by Phibro EPG, the participating laboratories were given a time frame to analyze the control samples and send in the results. Phibro tabulated the participant’s results, and compared those to the numbers for the control sample. The report included the concentration of each constituent analyzed by all participants and a summary of statistics from the data. Charts were produced for the mean, the upper and lower control limits (2-sigma from the mean) and the prepared (or true) values of each component. Results were reported anonymously, identified by a number known only by the participant rather than by name.

Participation in round robins provides laboratories with an opportunity to address several questions they may have about their analyses, including:

Advertisement

Advertisement

1. How accurate are my results versus the other participants and the actual control result?

2. Does my method, including such things as calibration practices or type of instrument, introduce a bias from the known value or does it provide results in a range similar to the other participants?

3. Do I misidentify or fail to detect constituents in the sample when compared to the other participants?

Advertisement

Advertisement

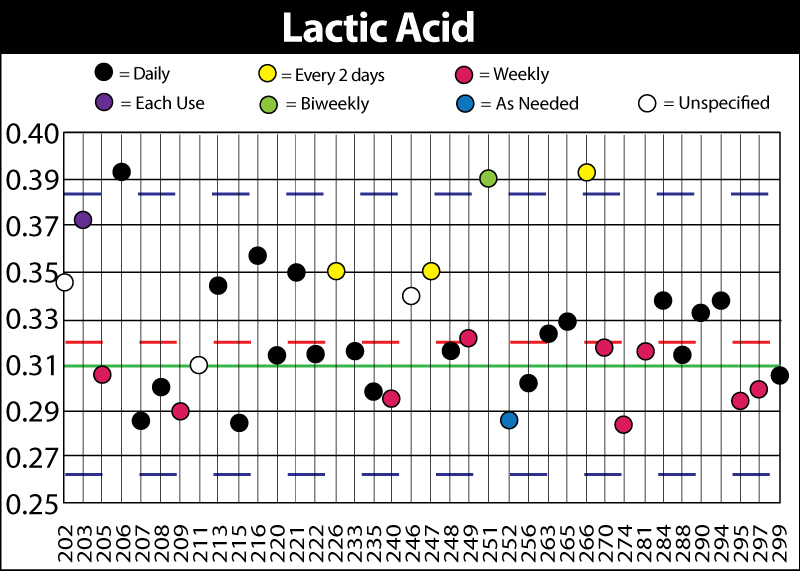

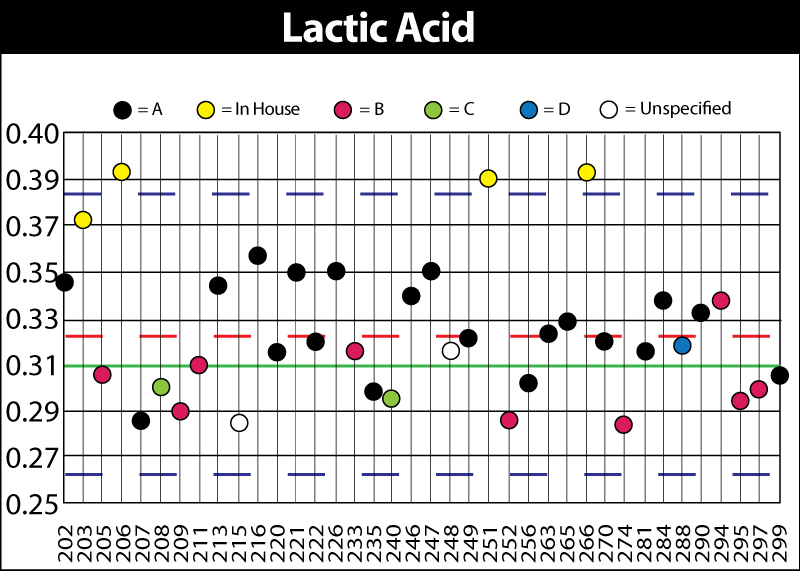

The Phibro team went beyond a simple representation of the tabulated results to compare other factors that may impact results, using a color-coded key to reflect the types of equipment and calibration practices in use at participating laboratories. The factors compared for the HPLC round robin included:

• The instrument manufacturer.

• The column manufacturer.

• The length of column, whether long or short.

• The frequency of calibration.

• The source of the HPLC calibration standard, whether purchased from a commercial source or prepared in the lab.

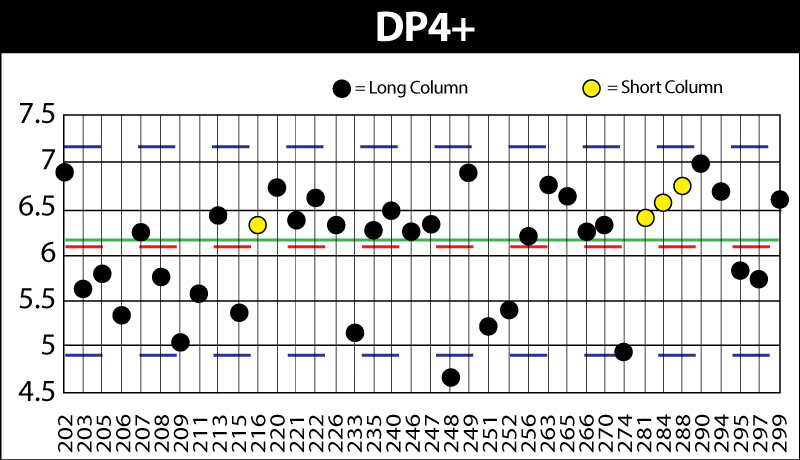

The accompanying charts answer common questions about how some of those factors impact results. The top chart, for instance, compares the results to see whether a short or long column provides a better determination of the glucose polymers (dextrin or DP4+, maltotrios and maltose). The middle chart begins to answer the question of whether the frequency of equipment calibration affects the accuracy of lab results.

Based on feedback from the first two rounds, Phibro EPG plans to expand the scope of the round robin studies to include additional microbiological and chemical analyses conducted at fuel ethanol plants. This program is a key initiative as part of Phibro’s ongoing customer support program to assist in optimizing customers' plant operations. It is the goal of Phibro EPG that future round robins will continue to provide clients with a resource to supplement internal laboratory testing and become an integral part of their own quality assurance programs.

Author: Wayne Mattsfield

Manager, Analytical and Microbiological Services

Phibro Ethanol Performance Group

651-641-2821

Wayne.Mattsfield@phibrochem.com

Related Stories

The USDA’s National Agricultural Statistics Service on June 30 released its annual Acreage report, estimating that 83.4 million acres of soybeans have been planted in the U.S. this year, down 4% when compared to 2024.

SAF Magazine and the Commercial Aviation Alternative Fuels Initiative announced the preliminary agenda for the North American SAF Conference and Expo, being held Sept. 22-24 at the Minneapolis Convention Center in Minneapolis, Minnesota.

Scientists at ORNL have developed a first-ever method of detecting ribonucleic acid, or RNA, inside plant cells using a technique that results in a visible fluorescent signal. The technology could help develop hardier bioenergy and food crops.

FutureFuel idles biodiesel production amidst regulatory uncertainty, shifts full focus to specialty chemicals growth

FutureFuel Corp. on June 17 announced it will temporarily idle its biodiesel facility upon completion of its remaining contractual obligations, anticipated to occur by the end of June. The company is shifting its focus to specialty chemicals.

The 2025 International Fuel Ethanol Workshop & Expo, held in Omaha, Nebraska, concluded with record-breaking participation and industry engagement, reinforcing its role as the largest and most influential gathering in the global ethanol sector.

Upcoming Events