Taiwan developers introduce high-yield biobutanol process

ITRI

November 7, 2013

BY Sue Retka Schill

Developers of a new biobutanol technology were in the U.S. Nov. 7 to receive the R&D 100 award from R&D Magazine for their new process which promises to convert 94 percent of the available carbon in biomass, including carbon dioxide, for a greenhouse gas reduction of more than 100 percent at a cost of less than $2 per gallon.

The trademarked ButyFix process was developed by Taiwan’s Industrial Technology Research Institute which is now looking for partners to take the process from the current bench scale to pilot scale development next year and demonstration scale within three years, said Chiang-Hsiung Tong, vice president and general director of ITRI’s Green Energy and Environment Laboratories.

Advertisement

Advertisement

Tong explained the ButyFix biobutanol process is multifeedstock capable and does not require uniform sizing, giving the example of one series of tests done with bagasse straight from the mill with just excess water removed before hydrolysis. The ButyFix process has three steps, starting with low-acid hydrolysis at 100 degrees Celsius and atmospheric pressure. “We use a solution of several acids,” Tong added, “and we can totally recycle them.”

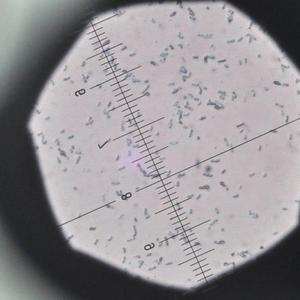

The fermentation step utilizes naturally occurring anaerobic bacteria that convert the sugars in a12-hour fermentation to butyrate. The high rate of carbon utilization is due to the microorganism’s ability to utilize the carbon dioxide generated in the fermentation. A liquid-to-liquid separation technique then removes the butyrate for conversion into butanol in the third step via esterification and hydrogenation.

ButyFix has achieved a butyric acid yield of 0.70 g/g-sugar, which is 94 percent of carbon conversion and 2.7 times higher in carbon conversion than the traditional acetone-butanol-ethanol (ABE) process. ButyFix has a theoretical maximum carbon conversion yield of 100 percent, ITRI reports, meaning that all carbon can be fixed in the product by fermentation if the process is optimized. By contrast, all other current fermentation processes for ethanol or butanol production have a theoretical maximum carbon conversion yield of 67 percent because of two molecular CO2 emissions per glucose molecule consumed.

Advertisement

Advertisement

ITRI holds four patents and six pending patents internationally on ButyFix technology including in Taiwan, China and the U.S.

ITRI is a nonprofit organization doing applied research on advanced technologies in multiple sectors including electronic, chemical, medical and energy and the environment. ITRI, headquartered in Taiwan, has offices in the United States, Japan, Germany, Russia and Netherlands. In the United States, it has long-term collaborative arrangements with MIT, Carnegie Mellon University, the University of California at Berkeley and Stanford University. Globally, it has 23 cooperative agreements with major companies such as IBM, HP, Microsoft, Nokia, Sun Microsystems, Kodak, Lucent and Motorola.

Upcoming Events