UT Bioenergy Initiative selects refinery site

Invalid Date

BY Susanne Retka Schill

"Grassoline" has been trademarked as the name for the fuel to be produced by the University of Tennessee's (UT) Biofuels Initiative. The name was chosen as a way to publicize the project and link it to switchgrass, one of the proposed feedstocks, according to Kelly Tiller, director of external operations for the UT Office of Bioenergy Programs. "It resonates with the public," she said.

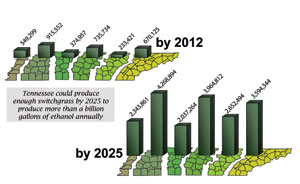

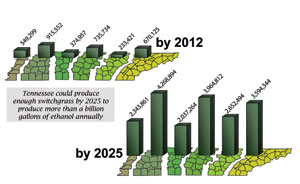

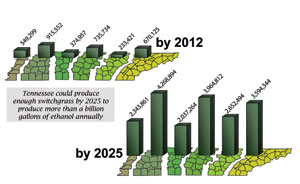

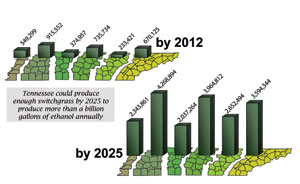

A public hearing was held in September to discuss Niles Ferry Industrial Park in Vonore, Tenn., as the site of the 5 MMgy cellulosic ethanol plant. The permitting process has begun, and Tiller said if all goes well, the project should break ground in early 2008 with the first gallon of Grassoline targeted for production by mid-2009. Full production would be slated for a year later. The time line projects that a commercial-scale facility will be on line by early 2012. UT will invest $40.7 million toward the capital costs of the facility, which Tiller said is intended to be research-oriented with built-in flexibility to study next-generation technologies as they emerge. Other partners include the state of Tennessee, Oak Ridge National Laboratory and private companies. At press time, details for the involvement of cellulosic ethanol developer Mascoma Corp. were being finalized. Tiller said other private companies may participate as other pieces of the project progress.

Tiller described the UT initiative as a comprehensive project that will not only optimize the conversion process, but develop the whole system from the farm up. "This is a brand-new crop, and energy markets are not something farmers are familiar with," she said. The state of Tennessee is contributing $8 million as an incentive for farmers to plant switchgrass, aiming for 8,000 acres in the program by mid-2008. UT is working on educational materials for farmers on establishing switchgrass, and recommendations for transport and storage. The project's next step includes the development of switchgrass varieties that would produce high yields and high sugars, the introduction of new pretreatment technology tailored to regional feedstocks, and the development of value-added markets for integrated coproducts.

A public hearing was held in September to discuss Niles Ferry Industrial Park in Vonore, Tenn., as the site of the 5 MMgy cellulosic ethanol plant. The permitting process has begun, and Tiller said if all goes well, the project should break ground in early 2008 with the first gallon of Grassoline targeted for production by mid-2009. Full production would be slated for a year later. The time line projects that a commercial-scale facility will be on line by early 2012. UT will invest $40.7 million toward the capital costs of the facility, which Tiller said is intended to be research-oriented with built-in flexibility to study next-generation technologies as they emerge. Other partners include the state of Tennessee, Oak Ridge National Laboratory and private companies. At press time, details for the involvement of cellulosic ethanol developer Mascoma Corp. were being finalized. Tiller said other private companies may participate as other pieces of the project progress.

Tiller described the UT initiative as a comprehensive project that will not only optimize the conversion process, but develop the whole system from the farm up. "This is a brand-new crop, and energy markets are not something farmers are familiar with," she said. The state of Tennessee is contributing $8 million as an incentive for farmers to plant switchgrass, aiming for 8,000 acres in the program by mid-2008. UT is working on educational materials for farmers on establishing switchgrass, and recommendations for transport and storage. The project's next step includes the development of switchgrass varieties that would produce high yields and high sugars, the introduction of new pretreatment technology tailored to regional feedstocks, and the development of value-added markets for integrated coproducts.

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events