New Process Uses SCP Technology

January 12, 2011

BY Rahul Bobbili

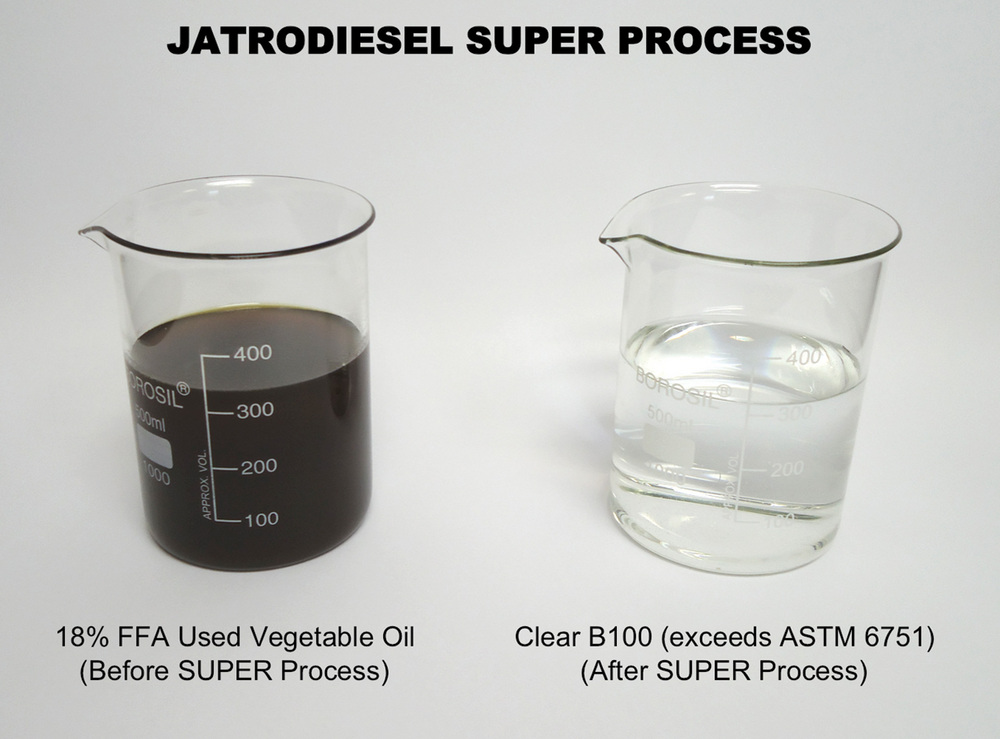

Ohio-based Jatrodiesel Inc. has launched its next-generation technology for biodiesel production. Trademarked Jatro Super, the biodiesel refining technique utilizes proprietary and patent-pending Solid Catalyst Process technology that has been under development for more than two years, and is lab- and pilot-tested at Jatrodiesel’s facilities in Dayton, Ohio.

The traditional biodiesel production process involves esterification for processing free fatty acids (FFA) into esters; and transesterification for processing low-FFA oils into biodiesel. The conventional process involves using sulfuric acid for esterification and sodium or potassium methylate catalysts for the transesterification process. These processes work very well and have decades of production experience behind them. Jatrodiesel has used these processes in six turnkey biodiesel plants it has built through the years. Virtually all functioning biodiesel plants in the U.S. use a form of these two technologies with similar, or exactly the same, catalysts.

The drawbacks of these traditional processing methods are formation of soaps and loss of yield, both due to high FFA processing (the higher the FFA, the greater the soap formation and yield losses); usage of fairly expensive catalyst; and, since multiple processes that are contaminant-sensitive require sundry pieces of equipment, high capital costs. Apart from these, another major drawback of the traditional process is the amount of training required for a new operator with no prior background to familiarize themselves enough to proficiently and safely run plant operations independently.

To address the above issues, Jatrodiesel developed a next-generation technology for biodiesel production trademarked Jatro Super, or SCP technology.

The new biodiesel technology is a single-stage process that eliminates esterification and transesterification, and puts no limit on feedstock FFA levels. The process requires an extremely small footprint and very low capital expenses compared to conventional methods. In addition, Jatro Super completely eliminates the need for traditional homogenous catalysts. In short, it cuts the cost of traditional biodiesel refining by a third. And, it requires little time for operators with no background in biodiesel processing to learn how to run the process.

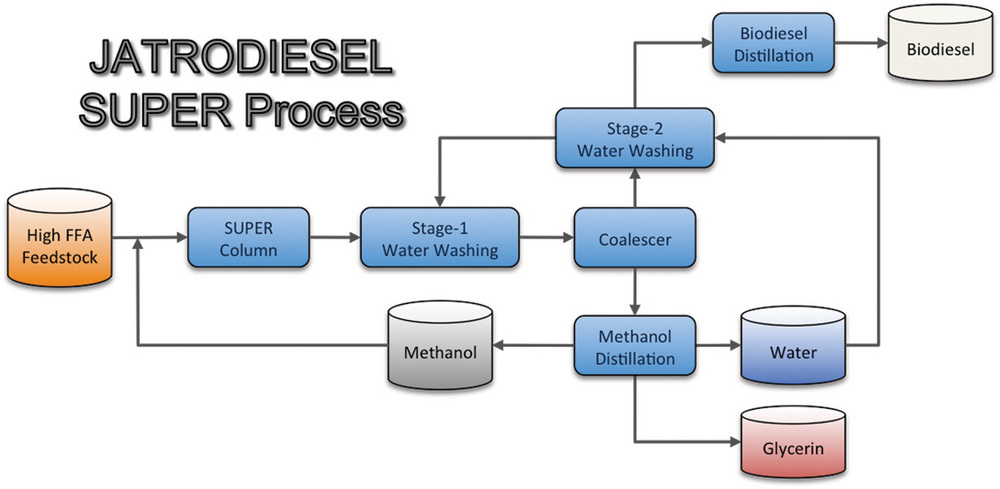

In the newly developed processing method, the feedstock is mixed with methanol and is introduced into the Super column, which employs a solid metal catalyst in a supercritical environment. The temperature and pressure is maintained in such as way in the process that the feedstock completely converts to biodiesel in a few minutes, with minimal or no loss in yield. Also, the water content of the feedstock has no effect on the process.

Advertisement

The mixture coming from the Super column is then sent through a separation process to isolate biodiesel from glycerin, and the excess methanol is recovered. The biodiesel is then either washed with water or through a waterless approach with magnesium silicate, to get rid of any excess glycerin.

The biodiesel coming out of this process meets ASTM D6751 specifications, and it can then be distilled to further clarify the properties.

The metal catalyst employed in the Super column should be switched out once a year at a minimal cost, which comes out to about one and a half cents per gallon of plant capacity per annum.

The advantages of the new process include:

• Lower production costs.

• No perceivable yield loss.

• No more ongoing catalyst consumption.

Advertisement

• No acid number issues for higher FFA feedstock.

• Higher glycerin purity due to no bleeding of homogenous catalyst.

• A number of processes are cut in half, thereby minimizing downtime and training required by operators.

• The area required for the process is cut by 60 percent.

• Low capital expenses.

For a typical 10 MMgy plant, the production cost using the Jatro Super process is 30 cents a gallon. That includes the cost of chemicals, energy, maintenance and payroll. For a comparable traditional plant, the cost is 45 to 48 cents a gallon. Coupled with lower production costs is the capability to process higher FFA feedstocks, up to 15 percent, and elimination of yield losses of 2 to 5 percent found in traditional processing methods.

Author: Rahul Bobbili

Vice President of Technology, JatroDiesel Inc.

(937) 847-8050 ext. 203

rbobbili@jatrodiesel.com

Upcoming Events