Diversified Technologies unveils algal oil extraction process

Photo: Diversified Technologies

February 25, 2011

BY Luke Geiver

One of the most promising methods for lipid extraction from algal biomass, electronic pulse technology that essentially ruptures algae cells via electronic pulsation or shockwaves, now has another company developing the process. Diversified Technologies, a Massachusetts-based company that specializes in large-scale power pulse modulators for national laboratories, radar stations, wastewater treatment facilities and food disinfection, has created an algal oil extraction process based on pulsed electronic field technology it calls the PowerMod.

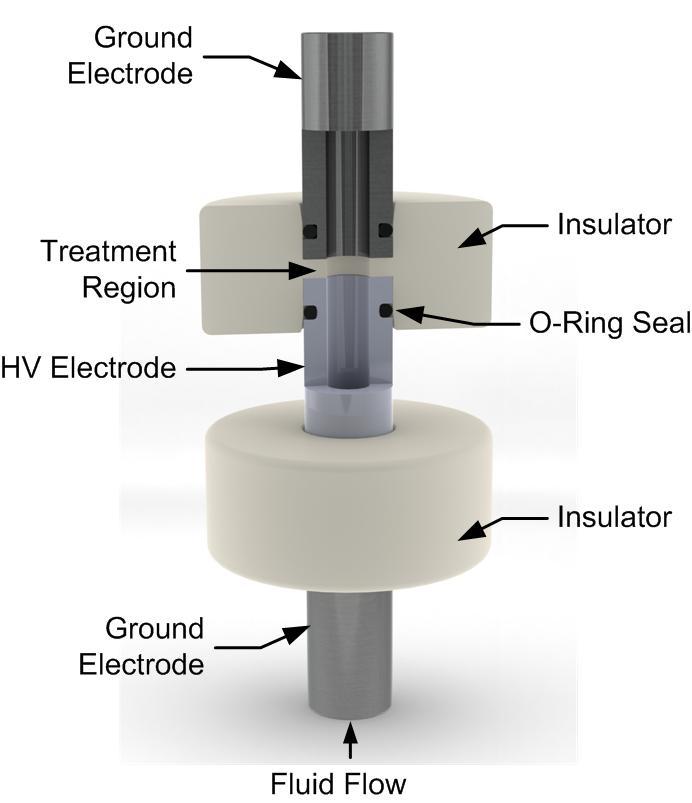

They system uses 10 to 30 kV/cm electric pulses for two to 20 microseconds in an algae slurry that will release the methyl hexadecanoate compounds. The process is based on electroporation, according to Mike Kempkes, vice president of marketing and electrical engineer for the company. The process, which has been known for decades according to Kempkes, applies a short, high-voltage pulse across a cell that opens the cell pores. The process has been used in genetic manipulation to move DNA in or out of a cell he says, and, “if you apply a large enough field for enough time, those pores actually rupture,” and release the compounds of the cell into the surrounding solution.

Nearly 10 years ago, the company started working with Ohio State University on a pasteurization approach that utilized a similar process. In 2001, Diversified Technologies built a large-scale system for OSU’s food science department. “A couple years ago,” Kempkes said, “we were contacted by some folks that were interested in algae biofuels, thinking this would make extracting lipids easier.”

After receiving a grant from the National Science Foundation, Kempkes and his team continued their testing on algae strains like isochrysis, chlorella and others he said he couldn’t name at this time. Now, he says, they are trying to find out what strains work best, how to optimize the system and how the breaking of algae cell membranes will impact downstream extraction processes. “The real objective is to see if you put a few cents per gallon up front in the PEF (pulse electric field) process does it reduce your extraction cost significantly more?” Early estimates show the unit will cost roughly 10 cents per gallon of biofuel made.

Advertisement

The work is currently in phase one of the NSF grant (which will end in June), which Kempkes says was given because the NSF “is looking for technologies and techniques that are going to influence renewable fuels.” The goal for the PEF technology he says is to gather enough data to bring to other parties or research efforts interested in partnering on a phase-two effort. “There is this large range of potential things that could be done, but the challenge is getting a set of data that shows what should be done.”

Advertisement

Upcoming Events