Battelle, Biobent get soyboard funding for bioplastic development

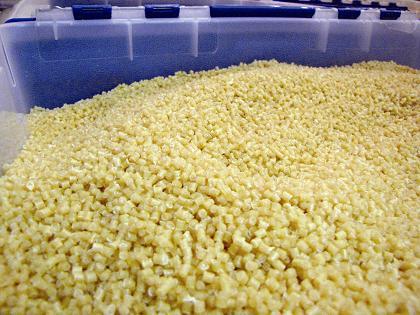

Photo: BioBent Polymers

February 21, 2012

BY Bryan Sims

The United Soybean Board has awarded Battelle funding specifically targeted to accelerate Marysville, Ohio-based bioplastics developer Biobent Polymers, a division of global plastics manufacturer Univenture Inc., in the commercialization of its novel biobased polymer resins using a Battelle-developed process derived from inedible soy meal, which can used as a replacement for virtually all petroleum-based polypropylene and polyethylene.

While well into its commercialization phase, the undisclosed amount of funding provided by the USB will enable Biobent Polymers to accelerate solutions dedicated to assessing and solving several key technical challenges, provide production capacity refinements and significantly expand the markets for its new family of soy-based biopolymers.

Advertisement

Advertisement

Funded by the Ohio Soybean Council, researchers at Battelle developed a patent-pending process to combine soybean meal with off-the-shelf plastic resins. The resulting biocomposite replaces 10 to 40 percent of petroleum-based resins. Created in 2011, Biobent has done most of its testing specifically around injection-molded products but, according to Keith Masavage, chief of strategy and operations for Biobent Polymers, there’s a huge market for film-related applications, sheets applications with vacuum forming and nonwoven materials for its soybased biopolymer resins.

“Part of the research that Battelle is looking into with this money is to find out what kind of requirements are there to enter into those markets,” Masavage told Biodiesel Magazine. “A lot of people have done a lot of work with bioplastic fillers, but what Biobent and Battelle are doing is that we aren’t making just simple fillers but rather we’re actually bonding the soy to the carbon chain of the polymer at the molecular level.”

Other technical and performance-enhancing objectives expected to be worked on as part of the USB funding, according to Masavage, include improving color, odor, performance and understanding protein and carbohydrate composition of the biopolymer.

Advertisement

Advertisement

“One of the things that Biobent is still committed to doing is being the first company out there that’s absolutely going to deliver the performance that people want, but do it at a price that’s competitive with petroleum-based plastics,” Masavage said. “Every time you add a step into your biorefining…the minute you touch them you increase your cost. We’re paying close attention to exactly what can be done, how efficiently it can be done and at what cost.”

Upcoming Events