A Closer Look at Sliding Vane Pump Technology

May 14, 2008

BY Tom Stone

Having been called the "fastest-growing alternative fuel" in the United States by the U.S. DOE, there's no question that biodiesel will continue to play an increasingly significant role in the nation's future motor-fuel supply. In fact, in 2006 the Congressional Budget Office and the USDA confirmed that biodiesel is the lowest-cost alternative fuel option for meeting the Energy Policy Act of 2005's alternative fuel use requirements. Additionally, late last year President George W. Bush signed the Energy Independence and Security Act of 2007, which further expanded the renewable fuels standard and set a mandate of 1 billion gallons of biodiesel use by 2012. Because of its utilization of renewable feedstocks, energy efficiency, compatibility with the existing fuel-distribution infrastructure and ability to reduce greenhouse-gas emissions, biodiesel is the one alternative fuel that truly has the capability to make a difference in the nation's diesel-fuel use patterns today.

B100, sometimes called neat biodiesel, is most often blended with regular diesel fuel at an 80-percent diesel, 20-percent biodiesel ratio to form B20. The B20 blend, if formulated to conform to ASTM D 975, can generally be used interchangeably with diesel fuel for normal usage as long as the biodiesel meets the requirements of ASTM D 6751 and the cold-flow properties of the blend are adequate for the geography and time of year the fuel will be used. It can also be handled with most current technologies that handle petroleum diesel. In fact, in its B20 configuration, biodiesel has been shown to have very little, if any, adverse effects on compression-ignition engines, fuel-oil and heating-oil boilers, and turbines, or the pumps, hoses, seals, gaskets, swivels, loading arms, valves, fittings and other equipment used in its handling, transportation and storage. Users should be aware that the B20 may degrade faster than petroleum diesel if oxidizing metals such as copper, bronze, brass or zinc are present.

The introduction of any new fuel to existing storage and infrastructure requires due diligence of compatibility.

Limiting Causes of Concern

While federal mandates appear to guarantee a boost in the use of alternative fuels now and into the near future, in order to ensure their safe implementation into the motor-fuel pool, the companies that manufacture the equipment used for the processing, handling, transporting and storing of these up-and-coming fuels must first be confident in that equipment's ability to handle any new formulations. Material compatibility, operational reliability, maintenance requirements and energy savings are among the critical areas of concern for any manufacturer when designing and engineering new equipment.

As with any new fuel or chemical formulation, care has to be taken that material compatibility is ensured. With that in mind, studies have shown that although B20 is well suited for use with existing diesel technology, B100 and other higher biodiesel blends require special handling with equipment that has been engineered to be compatible with the fuel.

Specifically, B100 will degrade, soften or seep through some hoses, gaskets, seals, elastomers, glues and plastics with prolonged use. Compounds especially susceptible to degradation include nitrile rubber, polypropylene and polyvinyl materials. Nonmetallic materials that have been shown to be compatible with B100 include polytetrafluoroethene, some flouroelastomer formulations, various fluorinated plastics and nylon. Metals that are compatible with B100 include ductile iron, stainless steel, carbon steel and aluminum, while brass, bronze, copper, lead, tin and zinc are incompatible.

Material compatibility concerns aside, when it comes to the type of pump that is best able to handle biodiesel through its production, transportation and storage phases, pumps that feature sliding vane technology have proven to be efficient, reliable and environmentally safe options, while also providing energy-saving operation and low maintenance costs.

Invented more than 100 years ago, sliding vane technology is featured in positive displacement pumps that are ideal for handling thin liquids. By constantly improving and upgrading its performance, today's sliding vane technology is able to meet the demands of reliability, product-loss prevention, environmental protection and process efficiency in biodiesel production.

Overview of Sliding Vane Technology

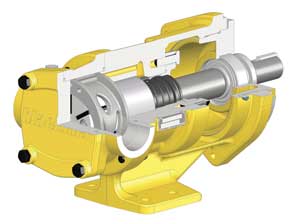

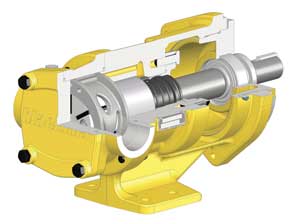

Sliding vane technology offers high efficiency and low maintenance advantages over traditional gear and centrifugal pumps. These are important factors in today's era of rising energy costs, lean personnel staffs and high demand for increased profitability. But these reasons are only part of a much bigger picture. For even greater flexibility, efficiency and productivity, advanced vane pump designs include motor speed technology, "designed in" features such as a hydrodynamic journal bearing and one mechanical seal. These features serve to further improve the fundamental pumping process in the manufacture of biodiesel.

The secret behind a sliding vane pump's enviable operational characteristics is the vanes that slide in and out of slots in the pump rotor. The pump's rotation draws liquid in behind each vane, through the inlet port and into the pumping chamber. As the rotor turns, the liquid is transferred between the vanes to the outlet where it is discharged. Each vane provides a positive mechanical and hydraulic displacement of the liquid. Vanes are actuated by three forces: 1) centrifugal force from the rotor's rotation, 2) push rods moving between opposing pairs of vanes, and 3) liquid pressure entering through grooves and acting on the rear of the vanes. Each revolution of a sliding vane pump displaces a constant volume of fluid. Variances in pressure have a negligible effect. Energy-wasting turbulence and slippage in the pump are minimized and high volumetric efficiency is maintained. The sliding vane technology also results in superior priming and suction capabilities, making the pumps suited for line-stripping, the evacuation of heels and pumping from underground or top unloaded storage tanks. Sliding vane pumps for biodiesel applications are available with capacities from 1 gallon per minute to 2,300 gallons per minute.

Recent advancements in sliding vane technology have increased the pumps' operation efficiency and longevity. Sliding vane pumps with hydrodynamic journal bearings eliminate shaft-to-bearing contact, meaning that there is virtually no contact or wear, resulting in superior bearing life and pump efficiency. Advanced sliding vane pumps can also include cavitation/noise-suppression liners that control the wear effects of cavitation and reduce noise levels up to 15 decibels. Compactly designed, motor-speed sliding vane pumps have been created for reliable continuous-duty operation. If need be, sliding vane pumps can be serviced with the piping attached, allowing for quick and easy maintenance. If the vanes become damaged, replacement is accomplished by removing the outboard head assembly, sliding out the old vanes, inserting new ones and reinstalling the head.

Taking note of the cautions that are required for the handling of B100, upgraded elastomer seals in many lines of sliding vane pumps allow for compatibility with all biodiesel blends. Flouroelastomer formulations have been upgraded to high-grade compounds that allow for much broader compatibility with a wider range of fuels. These elastomers are Underwriters Laboratories-listed and approved for all ethanol and biodiesel blends, including B100.

Conclusion

In the past, because of the continent's ready acceptance of diesel fuel and its corresponding technology, Europe represented nearly 90 percent of global biodiesel consumption. Of late, however, there has been a ramping up of biodiesel production in the United States. In fact, according to the National Biodiesel Board, production of the fuel reached approximately 450 million gallons in 2007, up from a scant 2 million gallons as recently as 2000. The NBB also reports that as of late 2007, 165 biodiesel manufacturing plants were on line in the United States with the capacity to produce 1.85 billion gallons of the fuel per year. In addition, another 80 plants were under construction and expected to be completed by mid-2009.

Therefore, with biodiesel production and use continuing to grow in the United States, there is a profound need for materials and equipment that are capable of handling its production, transportation and storage. With a century-old history of efficiently and safely handling thin liquids, sliding vane technology can handle the pumping requirements of a biodiesel plant, tank truck and railcar fleet, or storage facility.

Tom Stone is the director of marketing for Grand Rapids, Mich.-based Blackmer. Reach him at stone@blackmer.com or (616) 248-9252.

B100, sometimes called neat biodiesel, is most often blended with regular diesel fuel at an 80-percent diesel, 20-percent biodiesel ratio to form B20. The B20 blend, if formulated to conform to ASTM D 975, can generally be used interchangeably with diesel fuel for normal usage as long as the biodiesel meets the requirements of ASTM D 6751 and the cold-flow properties of the blend are adequate for the geography and time of year the fuel will be used. It can also be handled with most current technologies that handle petroleum diesel. In fact, in its B20 configuration, biodiesel has been shown to have very little, if any, adverse effects on compression-ignition engines, fuel-oil and heating-oil boilers, and turbines, or the pumps, hoses, seals, gaskets, swivels, loading arms, valves, fittings and other equipment used in its handling, transportation and storage. Users should be aware that the B20 may degrade faster than petroleum diesel if oxidizing metals such as copper, bronze, brass or zinc are present.

The introduction of any new fuel to existing storage and infrastructure requires due diligence of compatibility.

Limiting Causes of Concern

While federal mandates appear to guarantee a boost in the use of alternative fuels now and into the near future, in order to ensure their safe implementation into the motor-fuel pool, the companies that manufacture the equipment used for the processing, handling, transporting and storing of these up-and-coming fuels must first be confident in that equipment's ability to handle any new formulations. Material compatibility, operational reliability, maintenance requirements and energy savings are among the critical areas of concern for any manufacturer when designing and engineering new equipment.

As with any new fuel or chemical formulation, care has to be taken that material compatibility is ensured. With that in mind, studies have shown that although B20 is well suited for use with existing diesel technology, B100 and other higher biodiesel blends require special handling with equipment that has been engineered to be compatible with the fuel.

Specifically, B100 will degrade, soften or seep through some hoses, gaskets, seals, elastomers, glues and plastics with prolonged use. Compounds especially susceptible to degradation include nitrile rubber, polypropylene and polyvinyl materials. Nonmetallic materials that have been shown to be compatible with B100 include polytetrafluoroethene, some flouroelastomer formulations, various fluorinated plastics and nylon. Metals that are compatible with B100 include ductile iron, stainless steel, carbon steel and aluminum, while brass, bronze, copper, lead, tin and zinc are incompatible.

Material compatibility concerns aside, when it comes to the type of pump that is best able to handle biodiesel through its production, transportation and storage phases, pumps that feature sliding vane technology have proven to be efficient, reliable and environmentally safe options, while also providing energy-saving operation and low maintenance costs.

Invented more than 100 years ago, sliding vane technology is featured in positive displacement pumps that are ideal for handling thin liquids. By constantly improving and upgrading its performance, today's sliding vane technology is able to meet the demands of reliability, product-loss prevention, environmental protection and process efficiency in biodiesel production.

Overview of Sliding Vane Technology

Sliding vane technology offers high efficiency and low maintenance advantages over traditional gear and centrifugal pumps. These are important factors in today's era of rising energy costs, lean personnel staffs and high demand for increased profitability. But these reasons are only part of a much bigger picture. For even greater flexibility, efficiency and productivity, advanced vane pump designs include motor speed technology, "designed in" features such as a hydrodynamic journal bearing and one mechanical seal. These features serve to further improve the fundamental pumping process in the manufacture of biodiesel.

The secret behind a sliding vane pump's enviable operational characteristics is the vanes that slide in and out of slots in the pump rotor. The pump's rotation draws liquid in behind each vane, through the inlet port and into the pumping chamber. As the rotor turns, the liquid is transferred between the vanes to the outlet where it is discharged. Each vane provides a positive mechanical and hydraulic displacement of the liquid. Vanes are actuated by three forces: 1) centrifugal force from the rotor's rotation, 2) push rods moving between opposing pairs of vanes, and 3) liquid pressure entering through grooves and acting on the rear of the vanes. Each revolution of a sliding vane pump displaces a constant volume of fluid. Variances in pressure have a negligible effect. Energy-wasting turbulence and slippage in the pump are minimized and high volumetric efficiency is maintained. The sliding vane technology also results in superior priming and suction capabilities, making the pumps suited for line-stripping, the evacuation of heels and pumping from underground or top unloaded storage tanks. Sliding vane pumps for biodiesel applications are available with capacities from 1 gallon per minute to 2,300 gallons per minute.

Recent advancements in sliding vane technology have increased the pumps' operation efficiency and longevity. Sliding vane pumps with hydrodynamic journal bearings eliminate shaft-to-bearing contact, meaning that there is virtually no contact or wear, resulting in superior bearing life and pump efficiency. Advanced sliding vane pumps can also include cavitation/noise-suppression liners that control the wear effects of cavitation and reduce noise levels up to 15 decibels. Compactly designed, motor-speed sliding vane pumps have been created for reliable continuous-duty operation. If need be, sliding vane pumps can be serviced with the piping attached, allowing for quick and easy maintenance. If the vanes become damaged, replacement is accomplished by removing the outboard head assembly, sliding out the old vanes, inserting new ones and reinstalling the head.

Taking note of the cautions that are required for the handling of B100, upgraded elastomer seals in many lines of sliding vane pumps allow for compatibility with all biodiesel blends. Flouroelastomer formulations have been upgraded to high-grade compounds that allow for much broader compatibility with a wider range of fuels. These elastomers are Underwriters Laboratories-listed and approved for all ethanol and biodiesel blends, including B100.

Conclusion

In the past, because of the continent's ready acceptance of diesel fuel and its corresponding technology, Europe represented nearly 90 percent of global biodiesel consumption. Of late, however, there has been a ramping up of biodiesel production in the United States. In fact, according to the National Biodiesel Board, production of the fuel reached approximately 450 million gallons in 2007, up from a scant 2 million gallons as recently as 2000. The NBB also reports that as of late 2007, 165 biodiesel manufacturing plants were on line in the United States with the capacity to produce 1.85 billion gallons of the fuel per year. In addition, another 80 plants were under construction and expected to be completed by mid-2009.

Therefore, with biodiesel production and use continuing to grow in the United States, there is a profound need for materials and equipment that are capable of handling its production, transportation and storage. With a century-old history of efficiently and safely handling thin liquids, sliding vane technology can handle the pumping requirements of a biodiesel plant, tank truck and railcar fleet, or storage facility.

Tom Stone is the director of marketing for Grand Rapids, Mich.-based Blackmer. Reach him at stone@blackmer.com or (616) 248-9252.

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events