A Wiser Way to Handle Waste

PHOTO: DONG ENERGY

April 20, 2016

BY Ron Kotrba

Early this year, construction began on a unique plant at a 100-plus-year-old brownfield site near the historic blue-collar city of Manchester in the United Kingdom. Project owner Dong Energy calls it a “world’s first.” Using enzymes, the facility will produce biogas from 120,000 tons of unsorted household waste, equivalent to garbage from 110,000 residential homes. The fact that this waste is unsorted, meaning no prior separation of the digestible organics from recyclable inorganics, at the source (i.e., residents placing materials in designated bins) or the plant, is what’s truly unique about this project.

The process to be employed at the new biogas facility in Northwich, Chesire, is Dong Energy’s REnescience technology, which has been proven since 2009 at a demonstration-scale plant in Copenhagen, Denmark, where Dong Energy is based. According to Ulrik Falkenberg Lending, senior commercial manager for Dong Energy’s REnescience commercial division, the 1-ton-per-hour demonstration plant has logged more than 15,000 hours of run time, testing a variety of wastes from European markets, at various settings using different enzymes.

“The REnescience technology started its first development back in 2005, as a spin-off from the Inbicon technology—proprietary technology using enzymes with biomass also developed by Dong Energy,” Lending says. As in any proper scale-up, the REnescience technology was first proven in Dong Energy’s laboratory, followed by pilot-scale production prior to commissioning of the demonstration plant in 2009.

“With the REnescience Northwich Plant, the technology is now taken to a full-scale commercial level,” Lending says. He adds that important knowledge and improvements have been gained from the lab, pilot and demo plants over the past decade. “The decision to build the first plant is a very important step in our roll-out of the REnescience biotechnology,” says Thomas Dalsgaard, executive vice president of Dong Energy. “This is an entirely new way of treating household waste where we very effectively can ensure that we get as many resources as possible from our waste.”

The waste will be supplied by the U.K. waste management company FCC Environment, which already collects household waste in the region. “This is an exciting new technology for the disposal of municipal residual waste, which is potentially set to revolutionize our thinking as an industry of what can be achieved,” says Richard Belfield, group development director with FCC Environment. “Not only does this technology convert waste into energy without the need for the combustion of the waste, it will, for the first time, be able to extract the valuable recyclable materials, which so far have been difficult if not out of reach in traditional municipal residual waste treatment processes.”

Lending says the plan is to subscribe to the U.K.’s Renewable Obligations scheme, “which is a subsidy paid to producers of green energy,” he explains. While much of the feedstock will be ordinary “black bin” household waste containing food, paper, plastics and metal, Lending says some of the areas from where FCC Environment collects have source segregated separate collection in place. In addition to the RO subsidy, Dong Energy will receive a tipping fee from FCC Environment when it receives the waste, as is customary in the U.K.

“The solutions available on source separation have not delivered high recycling targets, even when combined with traditional material recovery facility and mechanical biological treatment technologies,” Lending says. “In addition, the full solutions are overall fairly expensive.” Source separation solutions from high-rises in particular have not given good results, according to Lending. This means untold tons of valuable recyclables from the most dense population centers are potentially headed for landfills, wasting precious resources and degrading the environment. For this reason, the ability for Dong Energy’s REnescience technology to take in unsorted household waste is vital.

The Process

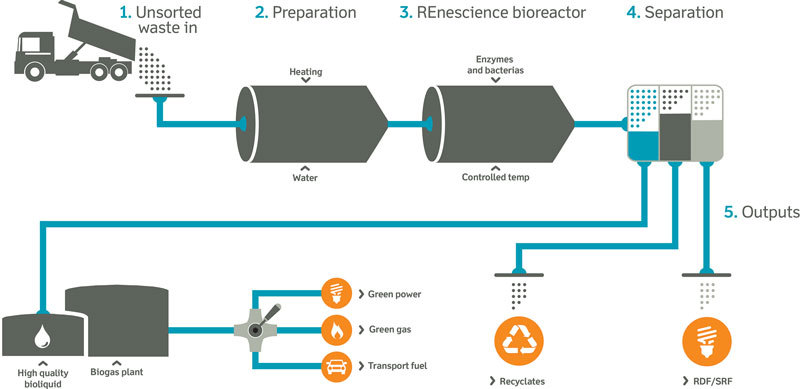

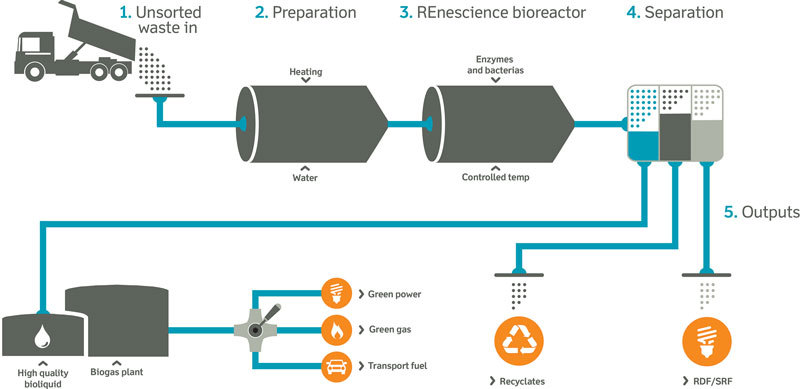

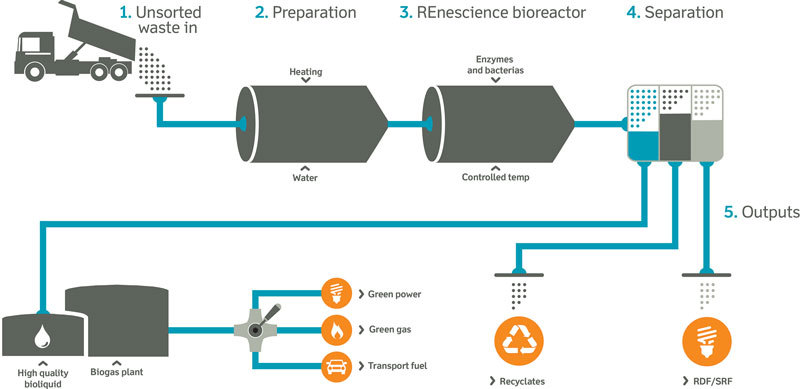

While no prior sorting is required, big, bulky items such as “white goods”—refrigerators, washers, dryers, air conditioners—are screened out and will not be put into the system. Sorting of other recyclable material will eventually take place on-site, but only after the waste has been through the bioreactors. “Only big, bulky items are screened out prior to the waste being mixed with waste and enzymes,” Lending says. “All the remaining mixed organic and inorganic wastes go into the bioreactors.”

Here’s how the process works. The REnescience Northwich Plant will take in unsorted household waste and treat the mixed materials gently with water, enzymes and enough heat for enzymatic hydrolysis. “No shredding or cutting of the waste is performed, and there is only slow, gentle movements in the bioreactors,” Lending explains. This enables the solid fraction—the plastics and metals, for instance—to be separated from the nonsolid or liquid fractions at the end of the bioreactors, where Lending says all of the nonrecalcitrant biodegradables are converted into a homogenous bioliquid. “This has two important results,” Lending says. “First, all the biodegradables can be used to create green power and heat, or the biogas can be upgraded by washing out the carbon dioxide and injected into the gas grid. And second, the plastics and metals come out very clean, now ready and easily separated.”

In the ballistic separation process, the treated waste is separated into three components—a bioliquid fraction and two-dimensional (2D) and three-dimensional (3D) solid fractions. The 2D fractions are mostly materials such as plastic wraps, tin foil and cloth or textiles. The 3D items are plastic cartons, cans, bottles and the like. The 3D fraction is transported to a washing drum, where surface residues are cleaned using recycled wash water.

After the ballistic separator, the 2D fraction is transported to a press, where liquid with organic fibers and residues is separated and mixed into the bioliquid stream. The 2D fraction is washed to improve storage stability and retain as much biomaterial as possible. After washing, a second pressing takes place to increase dry matter content. When the bioliquid exits the ballistic separator, it is mixed with bioliquid from the first pressing of the 2D fraction.

Lending says that compared to other types of mechanical biological treatment technologies and biogas processes, the steps taken in the REnescience plant are essentially reversed. “Instead of trying to separate the organics from the inorganics by tearing up the waste to sort it and then prepare the organics for anaerobic digestion, the REnescience technology dissolves and makes the organics ready for anaerobic digestion and then the inorganics can be separated,” he says. This reversal of the process, so to speak, provides two main benefits in terms of recycling, according to Lending. “The biogas yield is high,” he says, “and the capture of recyclates is high, and they come out very clean providing for an attractive market value.” Inert materials recovered from the process will be funneled to the secondary aggregates markets as road filling, for instance, and residual items of no value will undergo a thermal process such as incineration or cement kilning.

Global Applications

The REnescience Northwich Plant is designed, financed, owned and operated by Dong Energy. Lending says capital expenditures to build the plant will be approximately $90 million for this first-of-a-kind endeavor. The company would not disclose operational costs. On a cost-comparison basis to other biogas processes, the REnescience Northwich Plant is competitive, according to Lending, not only in the U.K. waste market where it will increase recycling performance compared to alternative solutions for household waste and contribute to the nation’s landfill diversion ambitions, but also globally. “We see the business being robust in different markets with different fundamental drivers and economic conditions,” Lending tells Biomass Magazine. “The application of the REnescience technology can be structured and configured to meet different needs, depending on what the particular market interests are.”

He says Dong Energy is in the process of rolling out more REnescience plants globally. “The board of directors for Dong Energy sees the investment as an attractive investment, both standalone and for its potential to unlock a pipeline of coming REnescience plants in the U.K. as well as on a global basis.”

The plant is expected to produce enough biogas to generate 5 MW of electrical energy. Dong Energy is on track, according to Lending, to begin commissioning early next year.

“REnescience is a brilliant new technology and generates as many resources as possible from everyday household waste,” says Brent Cheshire, Dong Energy’s U.K. country chairman. “This new bio plant will see us handling waste in a much smarter way.”

Author: Ron Kotrba

Senior Editor, Biomass Magazine

218-745-8347

rkotrba@bbiinternational.com

Advertisement

Advertisement

Upcoming Events