Are Black Pellets Ready to Compete with White Pellets?

March 1, 2018

BY William Strauss and Laurenz Schmidt

Renewable energy and carbon emissions reduction policies in Japan, South Korea, Canada, Western Europe, and other nations support the use of pellet fuel as a substitute for coal in power stations. To date, investments in pellet conversions have been focused on regular, industrial wood pellets, sometimes called white pellets.

Advanced wood pellets, often called black pellets due to their appearance after thermal treatment, have long been touted as a superior fuel to conventional white wood pellets. Black pellets are supposed to address some of the potential shortcomings associated with white wood pellets for use as a substitute for coal in pulverized coal power plants. Black pellet key advantages that have been put forward over the years include the elimination of the need for dry storage and transportation, better grindability, less dust formation during handling and storage, and higher specific energy density. Black pellets generally refer to two distinct technological approaches to developing an advanced wood pellet: torrefaction and steam explosion (SE).

Torrefaction is a form of pyrolysis that results in partial thermal decomposition in the absence of oxygen. Typically, torrefaction is conducted between 200 degrees Celsius and 300 degrees Celsius to remove volatiles from the wood, and the resultant material is then densified into pellets. FutureMetrics has not analyzed any of the torrefaction technologies, but has analyzed, in detail, the Arbaflame technology for producing SE pellets.

FutureMetrics—not engaged in Arbaflame in any way—was given full access to its intellectual property and its 40,000-metric-ton-per-year SE pellet plant in Norway. The report that this article is based on is an independent analysis of the Arbaflame technology, and the company has granted FutureMetrics permission to publish the information in this article.

What is Steam Explosion?

The SE method of wood fiber pretreatment involves exposing the material to saturated steam. The steam temperature and pressure, and the time in the reaction vessel, determines how much of the hemicellulose degrades, and what fraction of the feedstock matter gets converted into volatiles and biochemical compounds. The subsequent steam explosion is the rapid release of pressure. This explosive expansion of water in the cell walls of lignocellulosic feedstocks causes a breakdown of the wood fibers into very small particles. The severity of the steam treatment is controlled such that the cellulose and lignin are minimally affected, while the hemicellulose is partially degraded. When compared to white pellets, the resulting material, after densification in a pellet press, has a higher specific energy content (gigajoules per cubic meter (GJ/m3), improved grindability, is hard and produces fewer fines, and its affinity to water is changed from hygroscopic to hydrophobic.

The steam explosion process causes the lignin to emerge on the surface of the fine wood fibers in the form of small beads. When the fiber is densified in the pellet press, these beads form a film-like surface coating of the broken-down wood fibers, and results in hard, highly water-resistant pellets that produce almost no fines.

Benefits of SE Pellets

Three major advantages of SE pellets are:

• In contrast to white pellets, SE pellets will not disintegrate when wet.

• SE pellets have a higher volumetric and gravimetric energy density than white pellets (~31 percent more GJ/m3). This means more energy can be stored or transported per unit of volume.

• Power requirements for pulverizing SE pellets at the pulverized coal power station are significantly lower than the power requirements for pulverizing white pellets.

These benefits have been promoted for several years. However, technological constraints and high production costs have prevented large-scale adaptation. In early attempts to manufacture SE pellets, energy consumption, mass and energy content loss, and problems associated with the characteristics of the gasses released from the SE reaction outweighed the advantages of the product. The ability of the SE pellet plant to run reliably has also been a challenge to the development of a competitive SE pellet sector.

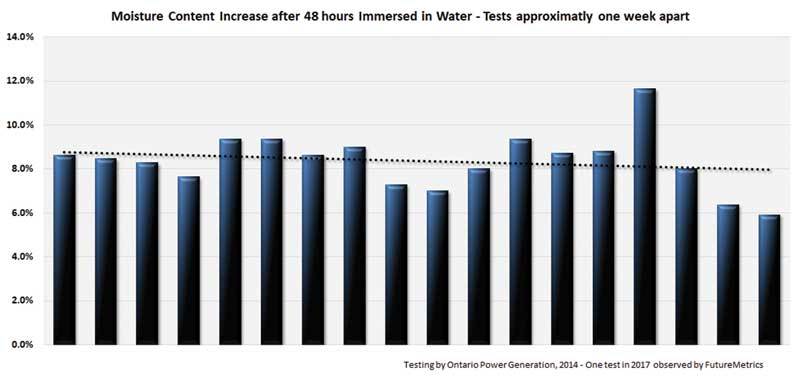

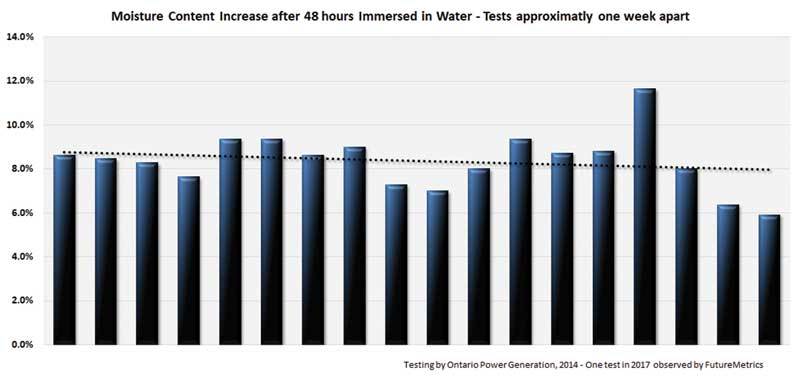

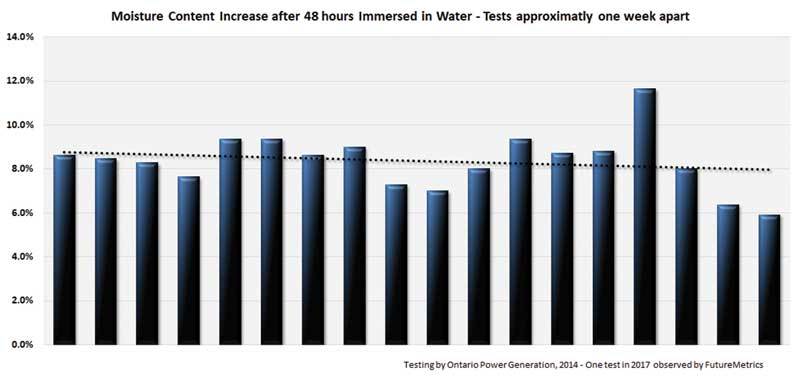

SE pellets absorb some water. As Figure 1 shows, after 48 hours of total immersion in water, the moisture content of the pellets increases from a the average after production of about 6 percent to about 14 percent. The water remains in the surface layer, and evaporates back out of the pellets.

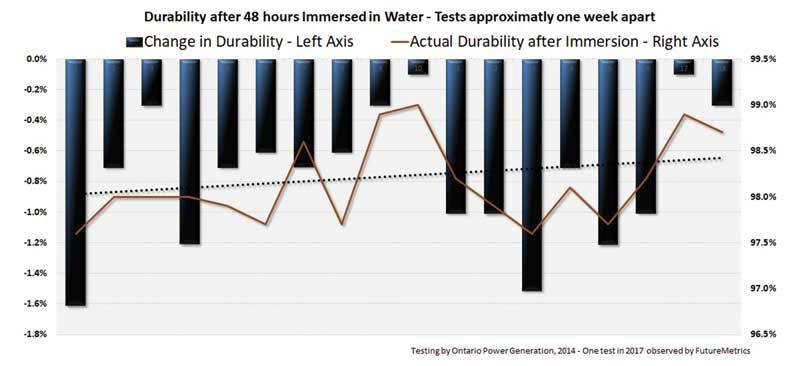

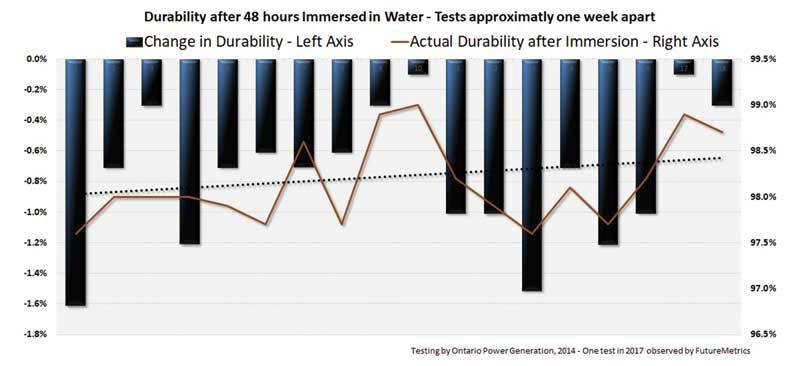

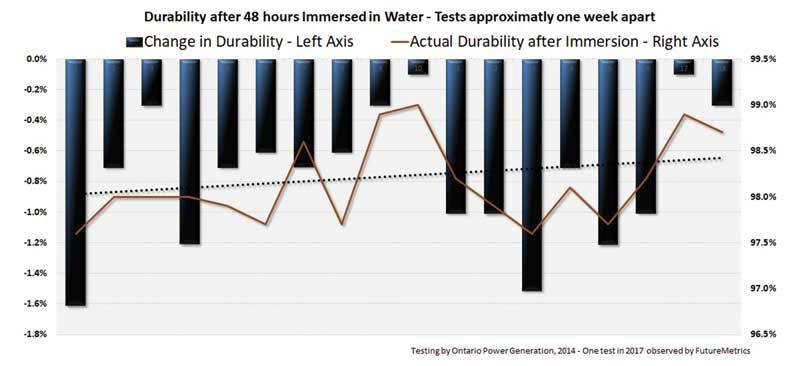

SE pellets do not lose their mechanical characteristics after exposure to water. The durability of Arbaflame SE pellets before water immersion averages 98.8 percent. As Figure 2 shows, after 48 hours of total immersion, the durability is between 97.5 and 98.5 percent. The ability to store SE pellets outdoors eliminates the need for costly dry storage domes, silos, sheds, or covered rail cars. It also allows ship loading and unloading during rain and/or snow events. SE pellets can be stored and handled under the same conditions, and in the same storage yards as coal, without detrimental impact on their functionality.

The impact of higher specific energy content (about 19.5 GJ/MT for SE and about 17.5 GJ/MT for white) and bulk density (about 790 kg/m3 for SE versus about 650 kg/m3 for white) on transportation costs per GJ delivered is another characteristic of SE pellets that gives them an advantage over white pellets. A fully loaded, 60,000-cubic-meter vessel (handymax size) will carry about 682,000 GJ of energy with white pellets, and about 924,000 GJ of energy with SE pellets.

Savings in the energy required to run the pulverizing mills in the coal power station can be significant. It takes about 45 kWh to pulverize one MT of white pellets. It takes about 11 kWh to pulverize one MT of SE pellets. This cost saving is particularly significant if applied to a Japanese independent power producer (IPP) project that is running under the feed-in-tariff. An IPP using 200,000 of SE pellets would consume enough fuel to fully fire a 60-MW unit for one year, and lower that plant’s annual pulverizer power costs by almost half a million dollars per year, versus what its cost would be to pulverize the same energy with white pellets.

Are SE Pellets Cost Effective?

Arbaflame, after more than a decade of R&D, has optimized the production process so that no energy is wasted. That optimization, plus the addition of a biochemical reclaim system to capture the valuable organic chemicals produced during the steam reaction process, allows the production of SE pellets that can compete with white pellets.

Recent developments in SE pellet technology by Arbaflame have substantially improved the competitiveness of SE pellets. The most relevant recent process improvement that lowered the cost of the previously noncompetitive process is the recycling of energy for use in feedstock drying and the recovery of valuable organic chemicals that are created as gaseous byproducts of the SE process. Many years of R&D by Arbaflame at its plant in Norway have also resulted in a pellet plant that operates reliably and consistently.

The Arbaflame SE pellet manufacturing process in operation at the Arbaflame 40,000-ton-per-year plant is robust and energy efficient. The plant runs reliably and consistently. The balancing of the moisture levels between the predryer output, the steam reactor, and the post dryer allows for nearly full utilization of process and post-dryer energy for the predrying process. This highly efficient use of energy is critical to the economics of the operation.

The mass loss due to steam treatment and the additional energy cost to run the reactor is offset by the value of the reclaimed biochemical compounds. SE fiber densifies more easily than white wood fiber. The lower operating cost of the pellet press (about 30 percent lower power per MT) and the elimination of the dry hammer mill (the SE process achieves the fiber size reduction needed for making pellets) further contributes to offsetting the higher wood cost per MT produced.

The ability to provide fuel delivery security to newly built power plants and co-firing power plants is critical. The white pellet sector has multiple production plants in numerous locations. If there is a problem at one plant or at a shipping terminal, there is redundancy across the supply chain. The SE pellet sector does not yet have that supply chain redundancy.

Based on our analysis, the only impediment to rapid growth in the SE pellet sector is that of overcoming the lack of redundancy in the fuel supply chain.

Authors: William Strauss

President, FutureMetrics

Laurenz Schmidt

Senior Engineer, FutureMetrics

www.futuremetrics.com

207-824-6702

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events