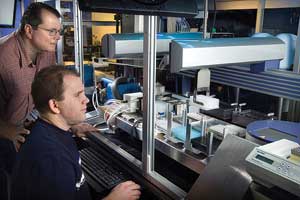

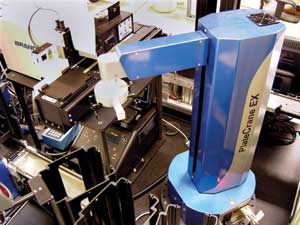

ARS robot allows for high-throughput screening

June 5, 2007

BY Nicholas Zeman

Ethanol science is a high-tech world of supercomputers, intense chemistry problems, and now robots that have automated crucial laboratory procedures for genetically engineering enzymes and yeasts traditionally performed tediously by hand. "You can tell a technician to transform 5,000 genes, but it's a very unhappy technician," said Stephen Hughes, a USDA Agricultural Research Service (ARS) molecular biologist who works at the National Center for Agricultural Utilization Research (NCAUR) in Peoria, Ill.

The aim of this research, which is powered by robotics, is to build genes from scratch and mutate them for superior ethanol-making characteristics. One example would be designing enzymes with higher temperature stability, but the ARS said particular emphasis is being placed on developing genetically engineered yeasts that can thrive in conditions that exist in industrial-sized vats where corn fibers like xylose are fermented into ethanol.

With the Saccharomyces yeasts used today, the ARS said 2.8 gallons of ethanol can be made from a bushel of corn. However, developing fiber-hydrolyzing strains could realistically help to squeeze 10 percent more ethanol from the grain crop by 2013, Hughes said. "We are using high-throughput robotic screening to transform the yeast so that ideally it would simultaneously express enzymes to break down the cellulose, as well as ferment the sugars once they become available," Hughes told EPM. "Traditionally in ethanol processing, enzyme pretreatment and fermentation have been separated." In addition, the ARS said that with genetically engineered yeasts, the goal is to make them perform several different functions, including making different products, while fermenting the sugars into alcohol.

The aim of this research, which is powered by robotics, is to build genes from scratch and mutate them for superior ethanol-making characteristics. One example would be designing enzymes with higher temperature stability, but the ARS said particular emphasis is being placed on developing genetically engineered yeasts that can thrive in conditions that exist in industrial-sized vats where corn fibers like xylose are fermented into ethanol.

With the Saccharomyces yeasts used today, the ARS said 2.8 gallons of ethanol can be made from a bushel of corn. However, developing fiber-hydrolyzing strains could realistically help to squeeze 10 percent more ethanol from the grain crop by 2013, Hughes said. "We are using high-throughput robotic screening to transform the yeast so that ideally it would simultaneously express enzymes to break down the cellulose, as well as ferment the sugars once they become available," Hughes told EPM. "Traditionally in ethanol processing, enzyme pretreatment and fermentation have been separated." In addition, the ARS said that with genetically engineered yeasts, the goal is to make them perform several different functions, including making different products, while fermenting the sugars into alcohol.

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events