Big on Bagasse

August 14, 2023

BY Keith Loria

It was just over two years ago when Jeanerette, Louisiana-based Delta Biofuel and Gov. John Bel Edwards announced that Iberia Parish was under consideration for the site of a first-of-its kind, $70 million renewable fuel plant utilizing bagasse, a byproduct of sugar manufacturing. for fuel pellet production. This past July, the project—which was able to overcome challenges that included inflated project costs—finally broke ground. “Our goal for the past two years was to get the facility designed and financed so we could start construction,” says Delta Biofuel CEO Philip Keating. “On May 16 of this year, we finally got to financial closing, and we have $115 million in financing to build and start up the plant.”

Albeit not unusual in biofuel project development, financing proved to be a bit of a challenge, as the project saw a 43% increase from the original estimated cost. These were large in part due to capital expenditures, higher labor and equipment costs, as well as the company’s decision to boost production capacity to 340,000 metric tons annually from the 300,000 originally announced in 2021, according to Keating.

“It’s really the result of inflation and the tight supply,” he says. “We went back to our customers and said, ‘The plant is more expensive, help us to get it done,’ and we were able to raise the contract price on our sales to help support the price increases of the building. We were lucky that way, and had a lot of support from our customers.”

Now, the wheels are in motion as Delta Biofuel is in the process of purchasing equipment and preparing the project site. An official groundbreaking was held on July 12. When complete, the Iberia Parish facility will use bagasse to manufacture biomass fuel pellets on a commercial scale, offering a low-cost and strong greenhouse gas reduction profile.

In the Beginning

Delta Biofuel’s inception was in 2019, and although Iberia Parish is the company’s first bagasse plant, the team has been involved in various other renewable energy projects, including wind, solar, wood pellets and the bagasse business elsewhere in Louisiana. “This is the first commercial-scale bagasse pellet plant that we know of,” Keating says. “Our vision here is trying to put good use to the waste stream coming out of the sugar mills with respect to the excess fiber associated with the cane harvesting and sugar extraction.”

Millions of tons a year are produced in Louisiana and elsewhere, and it’s become a real problem for the sugar mills in terms of disposal. They use it for fuel for themselves, but they have much more than they can use and it becomes a disposal problem and de facto landfill. “The importance of this is multifaceted,” Keating says. “The first part is that we are solving a problem for the sugar industry, and by default, the communities they are in by getting rid of this material. They become liabilities for the mill owners and farmers.”

Another important thing about the process is bagasse pellets can serve as an alternative to wood pellets, or more importantly, the typical fossil fuels that wood pellets replace. “The power generation industry has been looking for multiple feedstocks for fuel, and bagasse is a good one for them to diversify,” Keating says. “The other thing that happens when you have a landfill is this stuff eventually decomposes and it emits methane, and that’s the worst of all greenhouse gasses. By taking the material and putting it to use, that methane is reduced.”

Ultimately, Delta Biofuel wanted to find a solution to alleviate bagasse disposal problems as much as possible, and came up with the plan for what Keating describes as “a relatively simple project and produce to manufacture and supply to facilities around the world.

“One of the nice things about this project is every group that it touches wants it to happen, which is kind of unusual in the project development world,” he says. “The sugar industry wants it, the state wants it, investors want it and our customers want it.”

The state and local government have been pro-bagasse plant since the beginning and have done their parts to help get the project moving forward. To support the project, the state of Louisiana offered Delta Biofuel an incentive package that includes the comprehensive workforce development solutions of LED FastStart, and a $1 million performance-based grant for infrastructure improvements. The company has also been approved for the state’s Industrial Tax Exemption program and has applied for the Quality Jobs program. “These are all really helpful to us,” Keating says. “In addition, as a project developer, all you can really ask for is timely feedback and turnaround of permits and things related to that, and they have been very responsive. It sounds like it’s not that big a thing, but having agencies responsive to help you move the project forward is huge. We’ve been able to clearly understand what we needed to do and they helped us through the permitting process.”

Combating Challenges

Of course, for a project of Delta Biofuel’s size, most often there are hiccups or complications. While the company was ready to go more than a year ago, Keating says, progress was slowed. “The market turned upside down—supply chain challenges developed and prices went out of control,” he says. “We could not lock in pricing for the equipment we wanted to buy. We had to wait for everything to settle down, and it wasn’t until about [February] when we were able to lock in. When you’re doing project finance and you have lenders and equity investors, it’s very hard to do in high volatile times, and we just couldn’t get it done for a while.”

But as 2023 broke, things began to settle down and Delta Biofuel was able to place orders with locked-in pricing and delivery times. “We’re finally past all of that,” Keating says.

Vendor Relationships

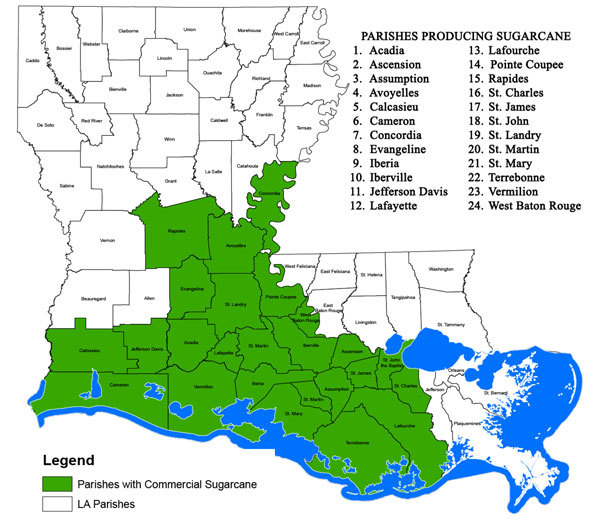

With the contracts in effect, Delta Biofuel has secured almost half the state’s sugarcane bagasse production. He notes than when viewing Louisiana on Google Earth, one can see two big tracks of cane land that come down either side of the Atchafalaya Basin, and the majority of the west side is contracted with the Iberia Parish plant. Delta Biofuel has secured exclusive long-term agreements to acquire bagasse feedstock from five nearby sugar mills to provide enough sugarcane waste for low-emissions energy generation. “We’re building the site at a sugar mill known as Enterprise Sugar Factory, owned by MA Patout, which is the largest sugar mill in Louisiana,” Keating says. “The facility will be located on leased acreage next to the sugar mill. Then, we’ve got other sugar mills from which we have contracted supply, where we will take their bagasse as it comes out of their facilities and manage it for them, and ultimately take it back to our facility to make pellets.”

The typical moisture content of the bagasse collected by Delta is between 50 and 70%, according to Keating. “Our drying system is a typical rotary drum dryer system much like you would see at a wood pellet plant,” he says. “It has been modified to handle the bagasse, and the dryer burners are fueled by bagasse dust.”

Much of the remaining equipment is also standard wood pellet process equipment, and like the dryer, has been modified as needed to handle the bagasse, including the hammermills and pelletizers. “It’s all from the wood industry,” Keating says. “But we do have a proprietary process for getting the dirt, ash and rocks out of the fiber, which is not typically in wood.”

Bagasse will be stored in a large pile in the existing area that the Enterprise sugar mill uses. “But we’ll have around-the-clock trucking in from other mills, which will be used as it's received, and not stored,” he says.

As for the final product, the energy content is around 16.8 megajoules (MJ), he adds—just slightly below the wood pellet standard of 17 MJ.

The company has entered into long-term contracts, primarily with power utility companies in Europe, for the sale of more than 1.8 million metric tons of pellets over the next several years. “The way we’re sending the material over, we’re partnering a port on the Mississippi—Impala Burnside Terminal—and they are constructing a 35,000-ton-capacity storage dome for us exclusively, which we will be sending our material to, and ultimately enough for large cargo ships to take across to Europe or anywhere else,” Keating says. “That’s another important part of the logistics.”

Final Steps

With the groundbreaking complete, it’s projected that it will take about 12 months for the plant to be constructed, with June 2024 slated for completion. “Once it’s up, we will immediately commission and begin start-up mode,” Keating adds. “And during startup and ramp-up, we will be producing pellets. Not full capacity, but we will be accumulating inventory to send to Europe. Full production is expected in September or October.”

Contact: Anna Simet

asimet@bbiinternational.com

-----------------------------------------------------------------------------------------------

Louisiana’s Sugar Cane Economy

Louisiana’s sugar industry has an annual economic impact of more than $2 billion to cane growers and raw sugar factories, while also generating an overall economic value of $3 billion. Sugarcane is produced on more than 480,000 acres of land, processed at 11 mills across the state.

The 2022 Louisiana sugarcane crop totaled a record-setting 17.1 million tons. Approximately 45% of total U.S. sugarcane production occurs in Louisiana, which trails only Florida in annual production.

Advertisement

Advertisement

Upcoming Events