Biodiesel and Feedstock Characteristics Report: A Summary

November 20, 2009

BY Glen Meier

What is the next big thing in biodiesel feedstocks? Will revolutionary new feedstocks be able to pass ASTM specifications for biodiesel? What will their fatty acid profiles look like?

New comparative research data is now available as a free, industry-wide resource to aid developers, suppliers and researchers determine the characteristics of various feedstocks. Armed with 15 years of biodiesel feedstock commercialization expertise and lab-scale pretreatment and production that mimic commercial processes, Renewable Energy Group Inc. has released its "Biodiesel and Feedstock Characteristics Report."

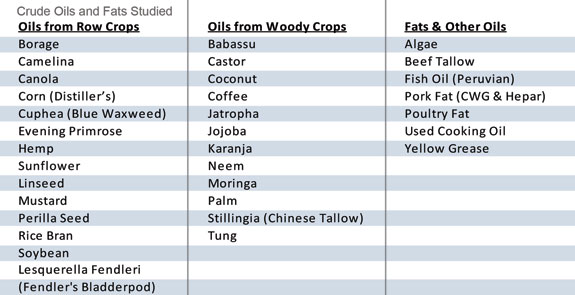

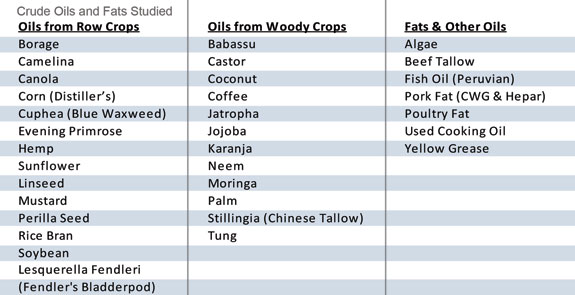

The report showcases benchmarks for traditional and unique oils and fats, as well as resulting biodiesel characteristics for more than 30 different, property-variant feedstocks.

Samples tested in the REG-produced comparison study include oils and fats already used in commercial biodiesel applications, such as soybean and canola oils, used cooking oil, poultry fat, beef tallow and corn oil removed from ethanol plant stillage. Other lesser known feedstocks characterized in this report, many of which are typically difficult to acquire and have not been widely studied or cited in industry literature, include coffee, rice bran, jatropha, algae, jojoba, fish and hemp oils.

With the onset of the revised 2009/2010 renewable fuel standard volume requirements, the biodiesel industry will require more than 1 billion gallons of biodiesel feedstock. As biodiesel production capacity grew drastically in recent years, multi-feedstock manufacturing capabilities improved across the industry.

These advances in biodiesel process technology, paired with increased finished fuel demand, necessitate sound feedstock science. What led REG's Technology and Feedstock Development team to propose this broad feedstock study was the demand for feedstock comparisons in empirical, repeatable studies in order to create an unbiased feedstock commercialization outlook.

Through a grant by the Iowa Power Fund administered through the Iowa Office of Energy Independence, REG completed the biodiesel industry's largest feedstock and B100 characterization study, combining feedstock quality testing and finished biodiesel quality testing results for more than 30 feedstocks. The results of the study are now available online at www.regfuel.com.

Apples-to-Apples Feedstock Comparisons

Each feedstock characterized in this study was obtained as a crude oil or fat; if a crude oil sample was not available, a refined oil sample was used. REG analyzed the oils and fats for components such as sulfur, magnesium, phosphorus, moisture and other characteristics. REG researchers also completed a fatty acid profile on each of the resulting biodiesel samples and have included those results.

Biodiesel was produced from each of the feedstocks and tested for compliance with ASTM D6751 specifications. To produce the biodiesel, REG designed a uniform method for pretreating the crude feedstock, esterifying the free fatty acids, transesterifying the triglycerides and filtering the finished methyl ester. The production method used in the study was based on a literature review and REG's extensive knowledge of biodiesel production techniques. Eliminating the variables of pretreatment and production allowed for a more direct comparison of the feedstocks. Each method is detailed in the published report to allow future research to build upon the data set.

Most feedstocks produced biodiesel that meet the ASTM specification, albeit with a wide variety of performance characteristics. Operational parameters such as cloud point, viscosity, density and cold filter plugging point produced a wide range of results in the study.

Two of the more technically interesting feedstocks in the study were castor oil, a woody crop oil, and Lesquerella, a row crop oil. Both oils had impressively low cloud points, however further evaluation found higher than expected cold filter plugging point (CFPP) temperatures. This was an interesting finding because CFPP is typically below cloud point.

Biodiesel made from castor oil was analyzed to have a cloud point temperature of minus 13.4 degrees Celsius but the CFPP was 7 C. Because fatty acid profiles were compiled for each feedstock, the REG team was able to attribute the very low cloud point of castor oil methyl ester to the presence of about 90 percent ricinoleic acid. Biodiesel made from Lesquerella oil also has a low cloud point temperature, minus 11.6 C. The methyl ester of Lesquerella contains about 66 percent of lesquerolic acid, which is similar to ricinoleic acid, leading to the low cloud point of methyl esters made from Lesquerella oil.

Although castor oil and Lesquerella oil boast low cloud points, their physical characteristics include higher than usual viscosities. Specifically, biodiesel from castor oil had a viscosity of 15.25 square millimeters per second (mm2/s) and Lesquerella had a viscosity of 10.02 mm2/s. The ASTM D6751 limit is 1.9-6.0 mm2/s. These explain the high CFPP values because CFPP depends on viscosity while cloud point does not. The fatty acid profile also explains the higher viscosity values.

This provides a good example of the value of the combination of fatty acid profile data paired with feedstock and finished fuel characteristics found in the final publication.

Oct. 1 marked the first day the Internal Revenue Service required B100 to pass cold soak filtration testing in order to qualify for tax credits. The REG study shows biodiesel with higher cloud points, such as the 16 C cloud point temperature of beef tallow, can still show very good cold soak results (76 seconds), and some with low cloud points such as tung biodiesel (minus 10 C) were unable to pass.

Full Study Results Available

Nowhere in the industry have this many feedstocks been compared in an apples-to-apples research format. This research provides current and potential biodiesel feedstock suppliers and producers with key information on the physical and chemical characteristics of both feedstock and finished fuel. The publication of these feedstock benchmarks and finished methyl ester characteristics represents a major advancement in answering market viability and commercialization questions for the biodiesel industry.

More than 100 pages of methodology and testing results are available free of charge to the industry. To learn more about the study, please contact Glen Meier. To download a copy of "Biodiesel and Feedstock Characteristics Report," click here.

Glen Meier is the director of technology and feedstock development for Renewable Energy Group Inc. Reach him at (515) 239-8035 or glen.meier@regfuel.com.

New comparative research data is now available as a free, industry-wide resource to aid developers, suppliers and researchers determine the characteristics of various feedstocks. Armed with 15 years of biodiesel feedstock commercialization expertise and lab-scale pretreatment and production that mimic commercial processes, Renewable Energy Group Inc. has released its "Biodiesel and Feedstock Characteristics Report."

The report showcases benchmarks for traditional and unique oils and fats, as well as resulting biodiesel characteristics for more than 30 different, property-variant feedstocks.

Samples tested in the REG-produced comparison study include oils and fats already used in commercial biodiesel applications, such as soybean and canola oils, used cooking oil, poultry fat, beef tallow and corn oil removed from ethanol plant stillage. Other lesser known feedstocks characterized in this report, many of which are typically difficult to acquire and have not been widely studied or cited in industry literature, include coffee, rice bran, jatropha, algae, jojoba, fish and hemp oils.

With the onset of the revised 2009/2010 renewable fuel standard volume requirements, the biodiesel industry will require more than 1 billion gallons of biodiesel feedstock. As biodiesel production capacity grew drastically in recent years, multi-feedstock manufacturing capabilities improved across the industry.

These advances in biodiesel process technology, paired with increased finished fuel demand, necessitate sound feedstock science. What led REG's Technology and Feedstock Development team to propose this broad feedstock study was the demand for feedstock comparisons in empirical, repeatable studies in order to create an unbiased feedstock commercialization outlook.

Through a grant by the Iowa Power Fund administered through the Iowa Office of Energy Independence, REG completed the biodiesel industry's largest feedstock and B100 characterization study, combining feedstock quality testing and finished biodiesel quality testing results for more than 30 feedstocks. The results of the study are now available online at www.regfuel.com.

Apples-to-Apples Feedstock Comparisons

Each feedstock characterized in this study was obtained as a crude oil or fat; if a crude oil sample was not available, a refined oil sample was used. REG analyzed the oils and fats for components such as sulfur, magnesium, phosphorus, moisture and other characteristics. REG researchers also completed a fatty acid profile on each of the resulting biodiesel samples and have included those results.

Biodiesel was produced from each of the feedstocks and tested for compliance with ASTM D6751 specifications. To produce the biodiesel, REG designed a uniform method for pretreating the crude feedstock, esterifying the free fatty acids, transesterifying the triglycerides and filtering the finished methyl ester. The production method used in the study was based on a literature review and REG's extensive knowledge of biodiesel production techniques. Eliminating the variables of pretreatment and production allowed for a more direct comparison of the feedstocks. Each method is detailed in the published report to allow future research to build upon the data set.

Most feedstocks produced biodiesel that meet the ASTM specification, albeit with a wide variety of performance characteristics. Operational parameters such as cloud point, viscosity, density and cold filter plugging point produced a wide range of results in the study.

Two of the more technically interesting feedstocks in the study were castor oil, a woody crop oil, and Lesquerella, a row crop oil. Both oils had impressively low cloud points, however further evaluation found higher than expected cold filter plugging point (CFPP) temperatures. This was an interesting finding because CFPP is typically below cloud point.

Biodiesel made from castor oil was analyzed to have a cloud point temperature of minus 13.4 degrees Celsius but the CFPP was 7 C. Because fatty acid profiles were compiled for each feedstock, the REG team was able to attribute the very low cloud point of castor oil methyl ester to the presence of about 90 percent ricinoleic acid. Biodiesel made from Lesquerella oil also has a low cloud point temperature, minus 11.6 C. The methyl ester of Lesquerella contains about 66 percent of lesquerolic acid, which is similar to ricinoleic acid, leading to the low cloud point of methyl esters made from Lesquerella oil.

Although castor oil and Lesquerella oil boast low cloud points, their physical characteristics include higher than usual viscosities. Specifically, biodiesel from castor oil had a viscosity of 15.25 square millimeters per second (mm2/s) and Lesquerella had a viscosity of 10.02 mm2/s. The ASTM D6751 limit is 1.9-6.0 mm2/s. These explain the high CFPP values because CFPP depends on viscosity while cloud point does not. The fatty acid profile also explains the higher viscosity values.

This provides a good example of the value of the combination of fatty acid profile data paired with feedstock and finished fuel characteristics found in the final publication.

Oct. 1 marked the first day the Internal Revenue Service required B100 to pass cold soak filtration testing in order to qualify for tax credits. The REG study shows biodiesel with higher cloud points, such as the 16 C cloud point temperature of beef tallow, can still show very good cold soak results (76 seconds), and some with low cloud points such as tung biodiesel (minus 10 C) were unable to pass.

Full Study Results Available

Nowhere in the industry have this many feedstocks been compared in an apples-to-apples research format. This research provides current and potential biodiesel feedstock suppliers and producers with key information on the physical and chemical characteristics of both feedstock and finished fuel. The publication of these feedstock benchmarks and finished methyl ester characteristics represents a major advancement in answering market viability and commercialization questions for the biodiesel industry.

More than 100 pages of methodology and testing results are available free of charge to the industry. To learn more about the study, please contact Glen Meier. To download a copy of "Biodiesel and Feedstock Characteristics Report," click here.

Glen Meier is the director of technology and feedstock development for Renewable Energy Group Inc. Reach him at (515) 239-8035 or glen.meier@regfuel.com.

Advertisement

Advertisement

Upcoming Events