Boiler MACT Impacts Biomass Power

March 4, 2013

BY Brandon Bell

The U.S. EPA’s National Emission Standards for Hazardous Air Pollutants for Major and Minor Sources: Industrial, Commercial, and Institutional Boilers and Process Heaters, or Boiler MACT has been a hotly contested regulation that imposes emission limits on new and existing combustion units with a heat input greater than 10 million Btu per hour. Since mid-May 2012, when the final rule was sent to the White House Office of Management and Budget, the industry has been patiently waiting for the formal release of the rule. On Dec. 20, EPA Administrator Lisa Jackson signed the promulgated rule, which is currently awaiting formal publication in the Federal Register.

Major vs. Area Sources

The amount of pollution generated by a biomass combustion unit will determine the type of pollutants that are regulated along with the level of reduction required. A firm understanding of the classification methods imposed by EPA is needed to determine which limitations will be imposed. Each facility will need to determine if it is, or will be designed to be, at pollutions limits that designate it as a major source or an area source, which is sometimes referred to as a minor source. As defined by 40 CFR 51.166(b)(1)(i)(a), there are three major criteria that are used to evaluate whether a facility is a major or area source. These are:

• Any individual criteria pollutant that exceeds 250 tons per year.

• Any individual hazardous air pollutant (HAP) that exceeds 10 tons per year.

• Combined HAP emissions that exceed 25 tons per year.

Criteria pollutants are contaminants that, when present in significant quantities, cause smog, acid rain, and other health hazards. These pollutants consist of oxides of nitrogen, volatile organic compounds, sulfur dioxide, fine particulate, and carbon monoxide. The Greenhouse Gas Tailoring Rule specifies a further six greenhouse gases that are also considered criteria pollutants. These six pollutants—carbon dioxide, methane, nitrous oxide, hydrofluorocarbons, perfluorocarbons, and sulfur hexafluoride are combined into a single regulated category called greenhouse gases. Currently, biomass facilities have a three-year exemption from this rule and do not have to calculate these emissions.

Hazardous Air Pollutants have been defined by Section 112 of the Clean Air Act and consist of 187 chemicals harmful to human health. If a facility exceeds any of the three thresholds outlined in 40 CFR 51.166(b)(1)(i)(a), then they are classified as a major source by the EPA. For scale, an approximate breaking point between major and area source regulations for a facility using clean virgin wood chips is approximately 25 MW gross. It should be noted that all emission sources from a facility are required to be included in these calculations. As an example, back-up diesel generators or diesel-fire water pumps are required to be operated for short periods of time for maintenance purposes. Emissions from these activities are to be included in the facility’s emission inventory.

Area Source Limits

An area source designation has significant benefits. For all new biomass area sources, the only regulated pollutant is filterable particulate matter (PM). Biomass boilers with a heat input between 10 MMBtu/hr and 30 MMBtu/hr are required to keep filterable particulate emissions below 0.07 lb/MMBtu, while boilers rated 30 MMBtu/hr and greater are limited to 0.03 lb/MMBtu. In addition to restrictions on particulate emissions, new biomass boilers will be required to conduct a biennial tune-up of the boiler.

Existing biomass facilities that have been classified as area sources have more relaxed restrictions than new units. Existing area source biomass units, regardless of heat input, do not have new limitations on filterable PM. These units will be subject to an initial tune-up, however, and will be required to conduct biennial tune-ups.

Major Source Limits

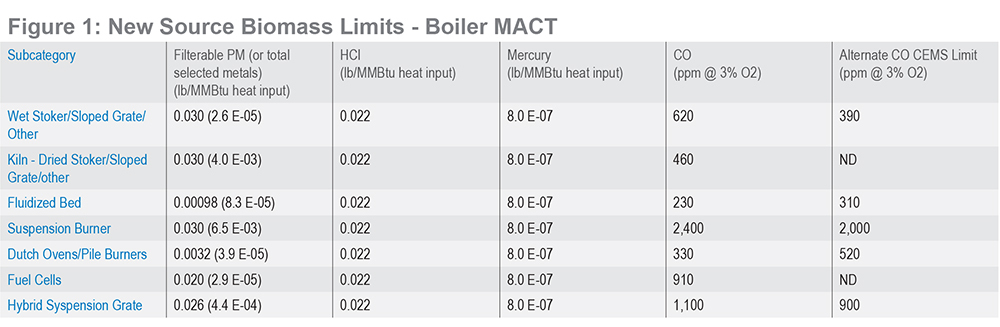

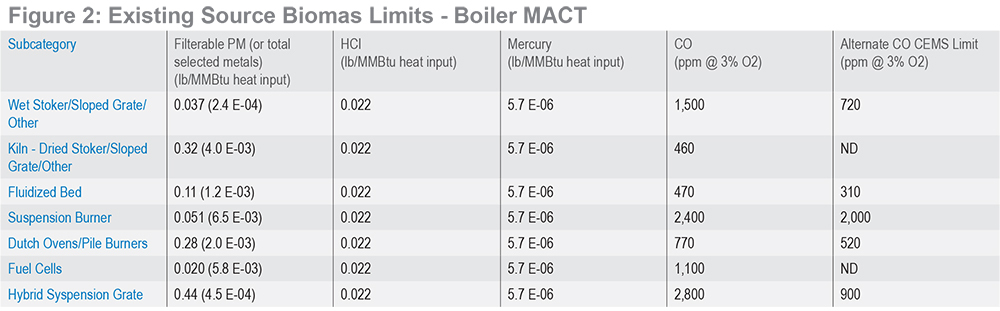

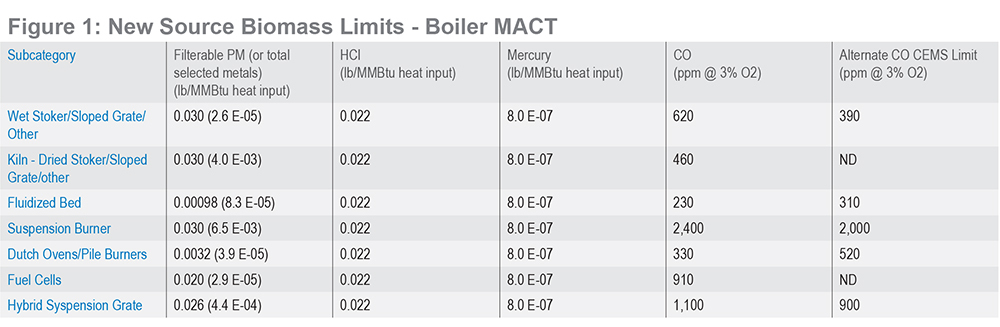

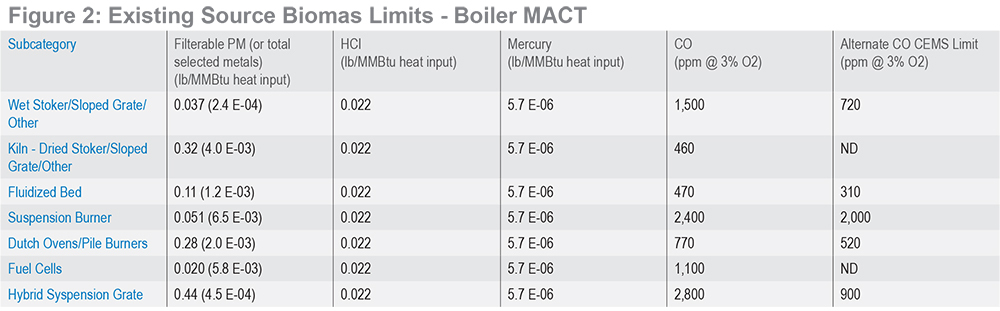

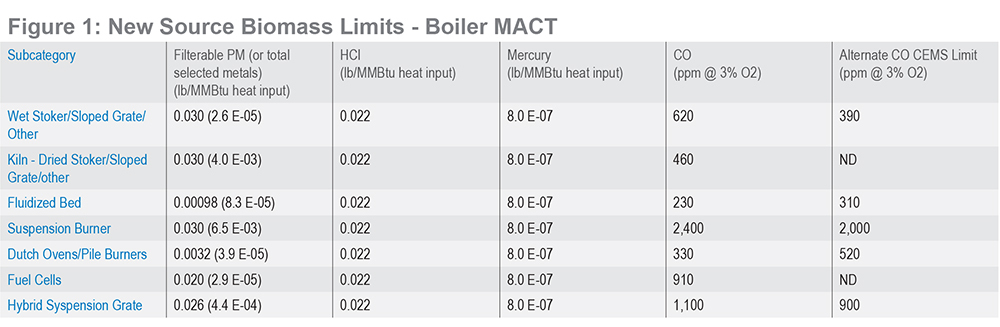

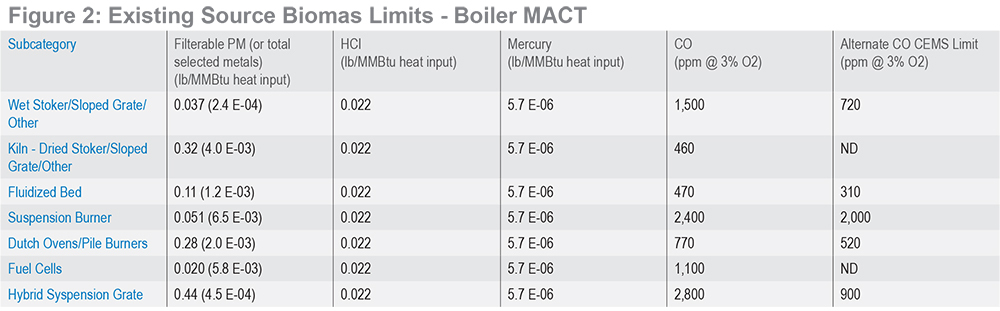

If a facility is classified as a major source under the EPA definitions, the Boiler MACT regulations impose further limits. The limitations outlined by Boiler MACT are divided into new and existing units, and then further detailed by the combustion technology utilized. The regulation also offers some flexibility when selecting which limitations will be imposed. Major source facilities must choose between a limit imposed on filterable particulate matter or on total selected metals. For the total selected metals category, the limitation is comprised of the summation of eight metals classified as hazardous air pollutants. These metals consist of arsenic, beryllium, cadmium, chromium, lead, manganese, nickel and selenium.

Unlike area source regulations, biomass facilities classified as major sources also have new limitations placed on carbon monoxide emissions. Some flexibility is also granted for these emissions. Compliance may be demonstrated through a three-run average or a 10-day rolling average monitored by a Continuous Emission Monitoring System.

Hydrogen Chloride, Mercury Back In

The proposed changes to the Boiler MACT regulation in December 2011 exempted biomass units, both new and existing, from limitations on mercury and hydrogen chloride (HCl) emissions. Unfortunately, the promulgated rule removed this exemption and now requires the control of HCl and mercury. The control of mercury is especially challenging for biomass units.

After the biomass combustion process, mercury present in the fuel will take one of three forms in the flue gas. These are elemental mercury (Hg0), divalent mercury (Hg++), or as a particulate. Mercury in a particulate form will be captured by particulate control devices, but mercury in an elemental or divalent state will pass through all emission control systems. Activated carbon will adsorb mercury and can be injected into the exit flues of a boiler at a particular temperature regime, but this process requires the mercury to be in a divalent state. To promote the capture of elemental mercury, it must first be forcibly ionized, typically through halogenation. With the mercury adsorbed onto the activated carbon particles, it can then be removed in a particulate control device.

Hydrogen chloride emissions can be controlled by either calcium or sodium-based sorbents. With this approach, calcium sorbents such as limestone or hydrated lime are injected directly into the upper furnace or other high-temperature region, and reduce the hydrogen chloride to calcium chloride. Sodium sorbents, such as trona or sodium bicarbonate, require an intermediate step prior to control of HCl emissions. Both trona and sodium bicarbonate require the process of calcination to form sodium carbonate. The sodium carbonate then reacts with hydrogen chloride in a suitable temperature regime to form sodium chloride.

Lasting Effect

It is estimated that, for all fuels, Boiler MACT will affect 14,136 boilers and process heaters classified as major sources and 180,000 boilers currently classified as area sources. Over the next three years, it is anticipated that 1,844 new major source boilers and 6,800 new area source boilers will be affected by this regulation. Deadlines to meet emission limitations are tight and must be addressed immediately, or facilities face noncompliance with the regulation. New area sources—those with a startup date after May 20, 2011—must meet emission regulations immediately, while existing area sources will have until March 21, 2014 to comply. New major sources—those which began operation on or after June 4, 2010—and existing sources will have three years from the publication date of Boiler MACT to meet the outlined limitations.

Capital expenditures for pollution mitigation equipment can be significant. Costs for sorbent injection systems and activated carbon systems can range from $21 to $65/kW depending on the size of the facility. Maintenance and operating costs will also increase substantially as activated carbon for the removal of mercury can cost upwards of $1,500 to $2,000 per ton and will add to fly ash quantities and disposal costs. All in all, operators should immediately start developing and implementing an action plan to meet compliance dates. Legal challenges to this regulation can be expected, but at best can only be expected to briefly delay implementation. They will not relieve industrial users of the obligation of meeting the current rule.

Author: Brandon Bell, P.E.

Principal Mechanical Engineer, KBR Power & Industrial

Brandon.Bell@kbr.com

312-846-7492

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events