Canada's Environmentally Sustainable Biodiesel Feedstock

January 12, 2011

BY Debbie Belanger

In increasing numbers, consumers have turned to canola oil as one of the world’s healthiest cooking oils. Livestock producers are choosing canola meal for its nutritional value as a feed additive; in dairy cows it can increase production by one liter of milk per cow per day. And, canola is being recognized as the best feedstock for biodiesel in cold weather climates.

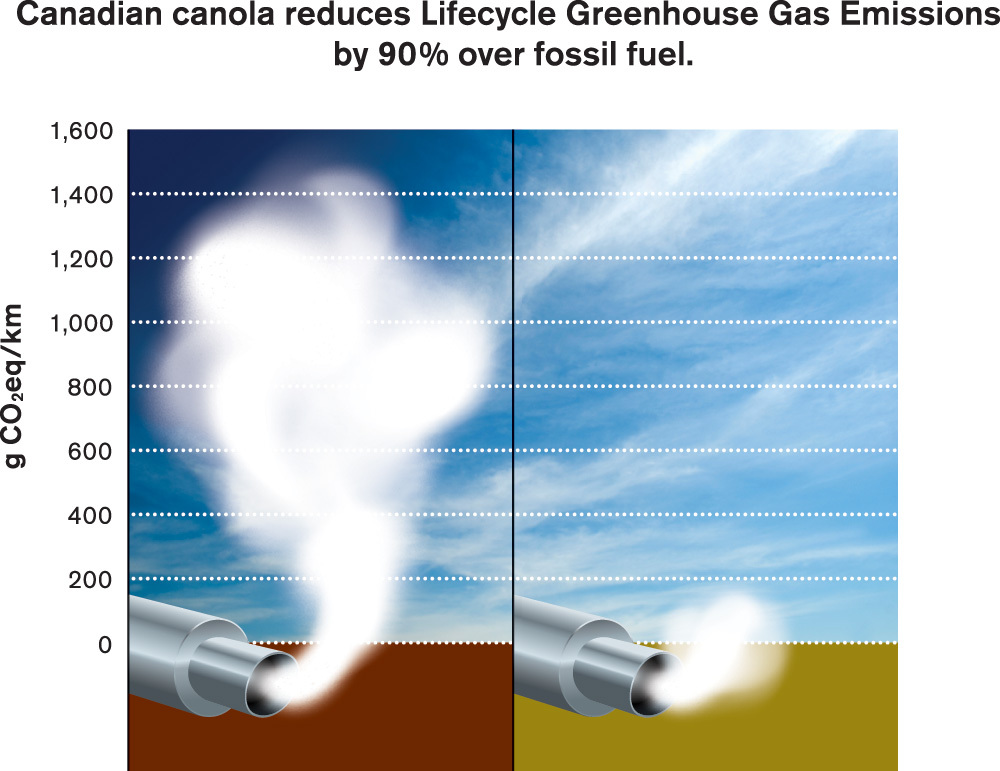

Now comes new information fuelling the case that biodiesel produced from Canadian canola is a green marketing advantage. The recently released study, “Life-Cycle Analysis (LCA) Canola Biodiesel,” demonstrates that canola biodiesel reduces life-cycle greenhouse gas (GHG) emissions by 90 percent compared to fossil diesel.

Authored by one of the world’s foremost experts on LCA, Don O'Connor, the study shows that Canadian canola biodiesel has substantially lower emissions for both the production and combustion stages compared to fossil fuels.

“This is a great story that not a lot of people have picked up on,” says O’Connor. “Canola grown in Western Canada, because of the relatively dry conditions, creates lower nitrous oxide (N2O) emissions, which are a big part of the emissions for any biodiesel feedstock. That, combined with efficient production practices such as conservation tillage, accounts for much of the reason that Canadian canola biodiesel reduces GHG emissions by so much.”

JoAnne Buth, president of the Canola Council of Canada, which commissioned the report, says, “It’s amazing when you think about it. Many countries, including the U.S., are establishing biofuel policies, and now we have clear data that shows Canadian canola can be a leader in meeting government policy goals on reducing greenhouse gases.”

From Seed to Tailpipe

Advertisement

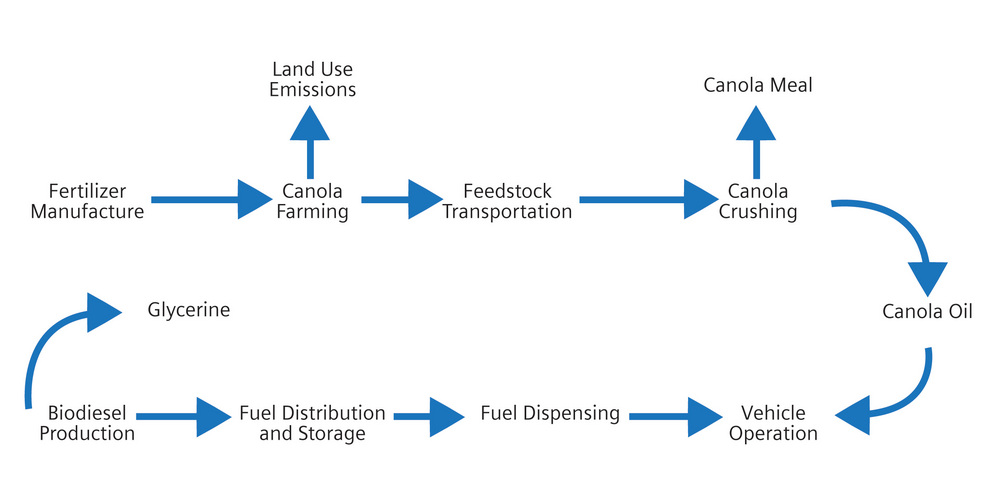

To understand the significance of the report, it is important to understand LCA. The term refers to the major activities in the course of a product’s life span from seed to tailpipe—that is, from the gathering of raw materials from the earth to create a product, to the point when all materials are returned to the earth. O’Connor’s report uses a highly credible LCA model developed by the Canadian government called GHGenius. GHGenius is capable of estimating the life-cycle emissions of the primary GHG emissions, and the criteria pollutants from combustion and process sources. It is also capable of analyzing emissions from conventional and alternatively fueled internal combustion engines and fuel cells for a wide variety of vehicles. The model can forecast emissions for past, present and future years considering several fuel-cycle segments.

These include fertilizer manufacture, land use emissions, feedstock transportation, canola crushing, biodiesel production, fuel distribution and storage, fuel dispensing and vehicle operation.

“Based on the results of using this model,” says Buth, “we have data demonstrating the environmental sustainability of canola as a feedstock for biodiesel.” Imagine that an agricultural crop had such a positive impact on producing carbon in the soil that it had the same effect as growing trees for carbon credits. Think yellow flowers, because the modern production methods for Canadian canola have resulted in Western Canadian agriculture now being a carbon sink. In fact, Canada is one of the few countries in the world building carbon in its soils. Here’s why.

Canola is the product of conventional plant breeding in the 1960s, which removed the antinutritional components from rapeseed, making it safe for human consumption. When canola came on the scene, the old crop rotation method was wheat to summerfallow, with plenty of tillage needed to keep down weeds. This caused soil erosion, high energy use, moisture on fallow land lost to evaporation, and poor economics for farmers having to leave their land fallow so much of the time.

Enter the canola producer and a new approach to rotation between wheat and canola and pulses, with crops seeded directly into stubble. Summerfallow has been replaced by productive land where moisture is conserved, and where disease management is achieved more through rotation and less through chemical means. With a reduction in tillage comes lower energy use, increased carbon stock maintenance in soil, a decreased rate of crop residue decomposition, and reductions in the amount of carbon released into the atmosphere.

Fueling U.S. Biodiesel Plants

Over the years, new hybrids and crop rotation practices have made Canadian canola a highly resiliant crop and a reliable supplier around the world. In fact, Canadian canola exports represent 80 percent of global canola trade. It is a $14 billion industry in Canada, and Canada-U.S. cross-border trade in canola and canola products was worth $1 billion in 2009, including 1.5 million metric tons valued at $600 million of canola seed and oil for U.S. biodiesel plants.

Advertisement

Canola from Canada supplies two major biodiesel plants in the U.S.: the Imperium Renewables Inc. Grays Harbor refinery in Hoquiam, Wash., and Archer Daniels Midland in Velva, N.D. They produce biodiesel for Canadian and U.S. markets and their capacity is 25 percent of the 2010 biodiesel mandate under the U.S. EPA’s renewable fuel standard of 650 million gallons (not the 2009-’10 combined volume of 1.15 billion gallons).

“We are very excited to see O’Connor’s report come out,” says Imperium President and CEO John Plaza. “This corroborates our own data that shows canola has an important role to play in reducing greenhouse gases.”

Imperium Renewable’s Grays Harbor refinery is capable of producing up to 100 million gallons per year of pure, unblended biodiesel refined from a variety of oils—canola grown in the Pacific Northwest and Canada, soy, and many other crops. Because British Columbia, Canada, is an important market for Imperium Renewables, the company also commissioned an earlier study by O’Connor to demonstrate its products meet the province’s low carbon fuel standards. The standards set thresholds for the carbon intensity of fuel, so the Imperium Renewables study analyzed both carbon in gasoline and diesel, and the carbon footprint of extracting, refining and transporting fuel to filling-station pumps.

“For the future of biofuels, life-cycle analysis is a critical component of our success,” says Plaza. “This new LCA report can be part of an education process for the public, customers and regulators to understand that canola significantly lowers GHG emissions. In fact, LCAs should be applied across all forms of energy.”

The future of canola biodiesel rests largely on the willingness of governments to set mandates for the inclusion of biofuels in gasoline and diesel. While the U.S. has done so through the EPA’s RFS2 and state mandates, the government of Canada implemented a 5 percent mandate for renewable fuels in December, based on the gasoline pool. A renewable fuels standard specifically for biodiesel is expected early this year. In Canada, the provinces of Manitoba, British Columbia and Alberta all have biodiesel mandates.

In the end, canola biodiesel, indeed the entire canola industry, depends on farmers’ willingness to grow canola.

Manitoba producer Brian Chorney says, “This report confirms the positive impact a renewable fuel standard for diesel fuel would have on the environment. It also confirms you get far more energy out of canola biodiesel than the energy put into producing it, compared to fossil fuel. We have a drum to beat here. From a grower perspective, we need to continue to develop more markets for our product. Increased demand from stable markets allows farmers the opportunity to increase supply while maintaining the return on investment farmers need to justify their investment in growing canola.”

Author: Debbie Belanger

Program Manager, Communications, Canola Council

(204) 982-2108

belangerd@canolacouncil.org

Upcoming Events