Comparison of Infrared Biodiesel Measurement Methods

September 10, 2012

BY Sandra Rintoul

There are several options for measuring the amount of biodiesel in diesel fuel. Methods EN 14078 and ASTM D7371 are more amenable to laboratory testing although waiting for an off-site laboratory to perform the test can take several hours to several days. For a driver whose truck has just been loaded for a delivery, any wait is too long. Other options for more simplified on-site testing that will track the official methods are available for those who need a quick verification check of the blend accuracy.

Official Biodiesel Methods

As biodiesel’s presence in the marketplace increased over the past 10 years, standards for verifying the amount of biodiesel blended into diesel fuel were needed. The first standard, which came out in November 2003, was EN 14078, developed by the European Committee for Standardization (CEN). ASTM International published a method for biodiesel content in diesel fuel in 2007, method D7371.

Why Infrared?

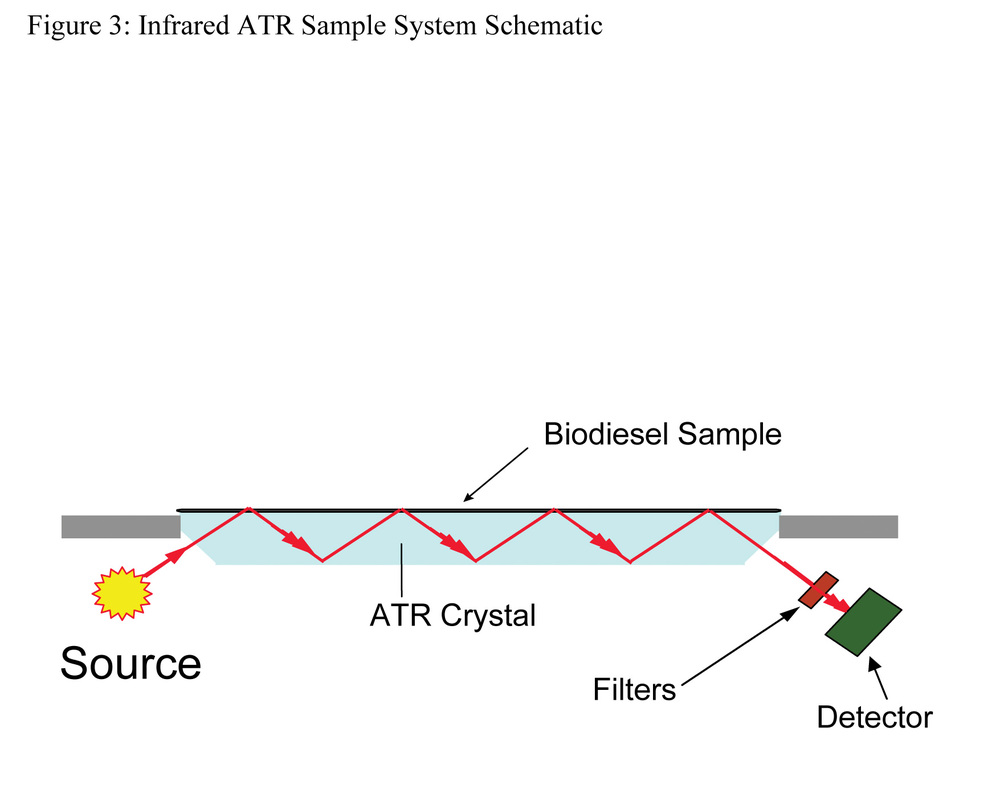

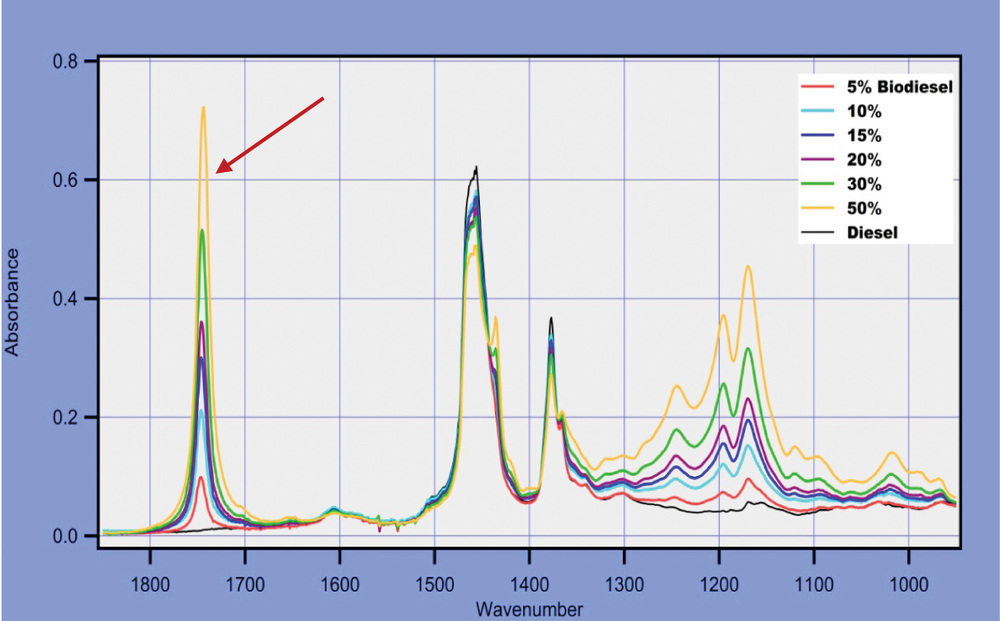

Both of these methods employ mid-infrared (IR) analysis as the measurement technology. Infrared is a common spectroscopic technique used for quantitative and qualitative analysis. In the biodiesel measurement, the fatty acid methyl ester (FAME) has a characteristic absorption at 1745 cm-1 (5.73 micrometers) due to the carbonyl group (see Figure 1). Both the EN and ASTM methods specify this wavelength for the biodiesel measurement.

EN14078 Method

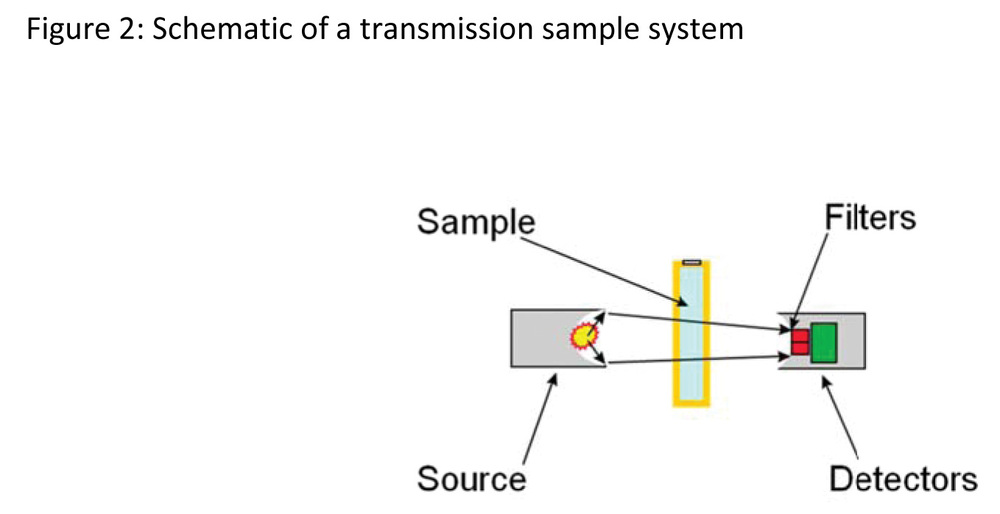

EN 14078 uses a transmission sampling cell typically with a 0.5 mm pathlength cell. The cell is filled with the biodiesel/diesel mix, then the IR light passes directly through the fluid and the amount of light absorbed by the biodiesel in the sample is measured (see Figure 2). The absorbance increases and decreases with the biodiesel concentration so the IR absorbance can be correlated with a concentration in percent.

Advertisement

Advertisement

Because a sample of biodiesel is completely absorbing with the 0.5 mm transmission cell, the samples need to be diluted with cyclohexane prior to analysis in order to be below the saturation point. For concentrations up to 11.4 percent, it is a 1:10 dilution. From 11.4 to 22.7 percent, it is a 1:20 dilution. Above 22.7 percent, the EN method states “adequate dilution ratios should be used in order to bring the absorption in the specified absorbance range of the calibration.”1

One challenge in this dilution process is the need to know the concentration of the biodiesel before testing the concentration. There is also an added chance for operator error in performing the dilution. Determining the “adequate dilution” for the “specified absorbance range of the calibration” would not be a straightforward task for operators at a fuel loading dock, which would make this method more amenable to a laboratory setting with trained technicians.

The short pathlength cell is also difficult to clean as stated in the EN method, “Because of the viscosity of FAME solutions, cleaning the cells used for measurement is of great importance.”1 Residual fuel in the cell could lead to errors in subsequent analyses.

The calibration procedure for EN 14078 is a relatively simple one that uses five standards of biodiesel blended in cyclohexane for a linear regression calibration. One concern with this calibration method is some diesel fuels have infrared absorbance in the region used for the biodiesel measurement that could offset the reading and is not accounted for in the calibration.

ASTM D7371 Method

As previously mentioned, with any IR analysis the diesel fuel formulation can have some interference in the reading. This is clearly stated in the interferences section of D7371, “The hydrocarbon composition of diesel fuel has a significant impact on the calibration model. Therefore, for a robust calibration model, it is important that the diesel fuel in the biodiesel fuel blend is represented in the calibration set.” 2

Advertisement

Advertisement

D7371 utilizes a chemometric partial least squares (PLS) calibration to try to reduce the baseline offset that could come from different diesel fuels. To avoid an unwieldy number of samples, the reasonable decision uses three diesels with varying aromatic contents to span the potential variation. The calibration requires 70 calibration standards. In addition to the carbonyl band, this method uses a second infrared absorption region (1371-1060 cm-1) for blend concentrations above 10 percent that has a less intense absorption from biodiesel.

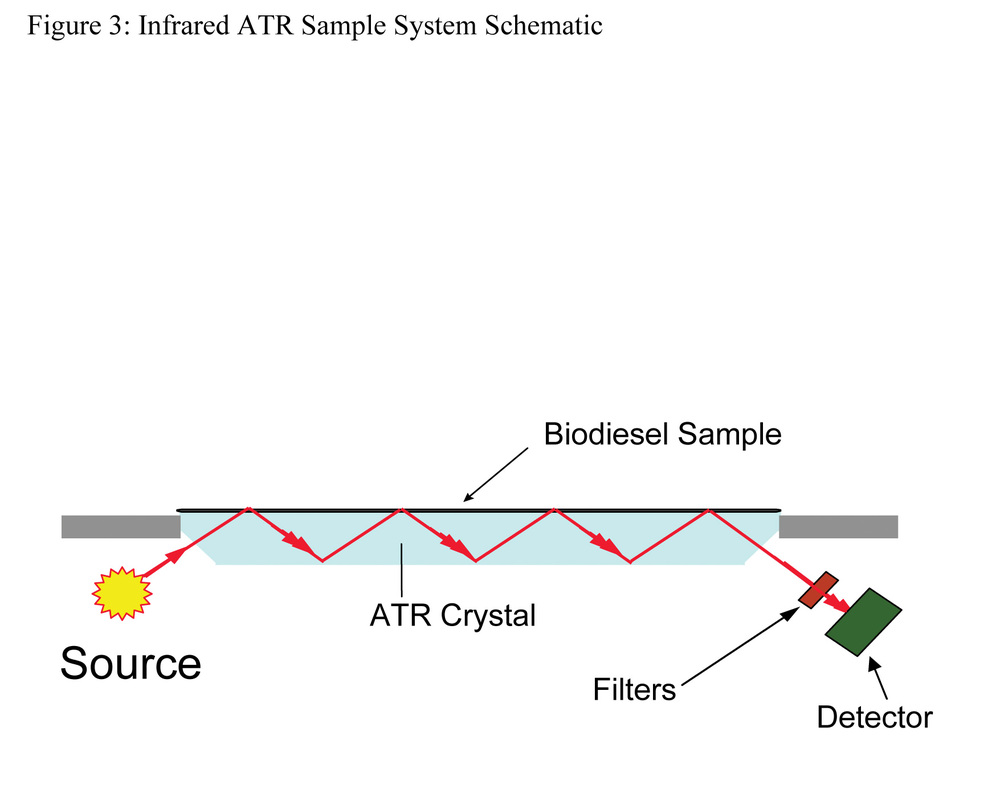

ASTM D7371 uses an attenuated total reflection (ATR) sample system to overcome the limited measurement range of a transmission sample system. With ATR, infrared light is focused onto one end of a crystal (such as zinc selenide or diamond) and the light bounces through the crystal penetrating about 1 micrometer into the sample that is placed on the ATR crystal. The light reflects back into the crystal and is focused back onto a detector for the absorbance measurement (see Figure 3). The short effective pathlength of the ATR crystal allows for a sampling range as low as 0.2 percent up to 100 percent biodiesel. The exposed ATR crystal is easy to clean, reducing the possibility of contamination in future samples.

Alternative Measurements

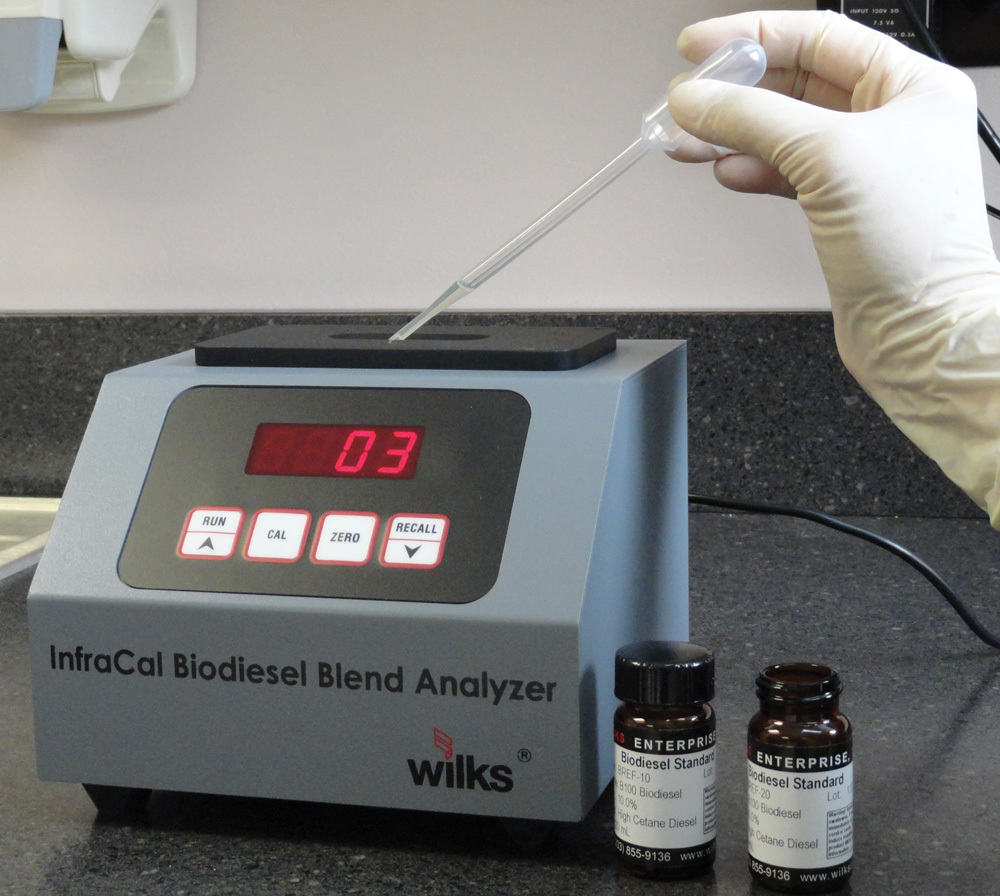

The apparatus specified in both ASTM D7371 and EN 14078 is either an FTIR (Fourier transform IR spectrometer) or dispersive mid-IR spectrometer. FTIR spectrometers are relatively expensive and usually operated in a laboratory by technicians who have had some formal training. For those individuals needing a quick blend check for distribution operations or blending audits, filter-based mid-IR systems (like the one pictured on page 32) are an option. These analyzers typically have no moving parts, making them rugged enough to be located at the loading rack at a fuel terminal or for operation out of a truck for testing at a fuel pump. Presently, there are no approved methods for filter-based infrared analyzers although two methods are currently in the ASTM process and could be approved by the beginning of next year.

One proposed method incorporates the most trouble-free portions of the current methods. It includes a calibration similar to the EN 14078 and uses the exposed ATR crystal from D7371. The ATR system allows for easy introduction and cleaning of the sample, as well as the extended measurement range from 0.2 to 100 percent without the need for sample dilution.

Conclusion

The method and analysis equipment you select will depend on regulations, possible concentration ranges for the biodiesel and where the measurement is needed. FTIR spectrometers have the analysis capability to do much more than a simple biodiesel blend and can comply with either the EN or current ASTM methods. Along with the increased capabilities, however, is added cost and complexity for the user. Filter-based infrared analyzers offer a simplified test method that allows for on-site biodiesel measurements by nontechnical personnel and is well-suited for applications that require a quick routine blend check. Whether you need a laboratory measurement or an on-site test, there is an infrared analysis method to suit your needs.

1. European Standard EN 14078: Liquid petroleum products–Determination of fatty acid methyl esters (FAME) in middle distillates

2. ASTM International D7371-07: Standard Test Method for Determination of Biodiesel (Fatty Acid Methyl

Esters) Content in Diesel Fuel Oil Using Mid InfraredSpectroscopy

Author: Sandra Rintoul

President, Wilks Enterprise Inc.

srintoul@wilksir.com

Upcoming Events