Daring to Design the Vehicle of the Future

August 3, 2007

BY Bryan Sims

As a young boy helping his big brother work on cars for a living, Matt Young knew somehow, someway he was destined to get his hands dirty working in the automotive industry. "I've always enjoyed working on vehicles," Young tells Biodiesel Magazine. "My brother was the big mechanic so I learned as much as I could when I was real young."

When he first started college he didn't know exactly what to pursue but he was interested in the engineering aspect of automobiles. So he decided to study computer engineering, which led him into designing automotive controls and eventually into a national vehicle design competition.

Young, a graduate student in electrical engineering at Mississippi State University (MSU), finally received the opportunity to put his childhood aspirations into practice when he joined the MSU Center for Advanced Vehicular Systems (CAVS). CAVS is an interdisciplinary center that allows engineering, research, development and technology transfer teams to focus on complex problems, such as those encountered in the technologies designed to improve human mobility.

At CAVS Young, with his background in computer engineering, learned the fundamentals of automotive controls and would later apply that valuable knowledge by participating in the 2007 Challenge X: Crossover to Sustainable Mobility event that was held at the General Motors Corp. (GM) proving grounds in Milford, Mich., May 30-June 7.

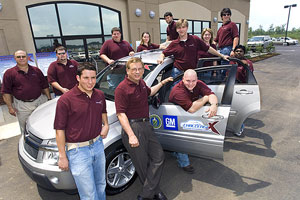

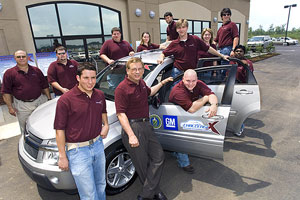

MSU placed first out of 17 schools that participated in the four-year competition that started in 2005 and ends in 2008. The teams were challenged to reengineer a GM-donated 2005 Chevrolet Equinox. The goal was to maximize the vehicle's fuel economy, and reduce emissions and greenhouse gases (GHGs) while maintaining or exceeding the vehicle's stock utility and performance. Co-sponsored by the U.S. DOE and GM along with several others, the groundbreaking national event just completed its third year. The sponsors supplied cutting-edge technology and support, including software and hardware components. The first year of the program focused on vehicle simulation, modeling, and subsystem development and testing. In 2006 and 2007, students were able to physically integrate their advanced powertrains and subsystems into the Equinox where they were judged on various categories which were calculated into a point system.

According to Micky Bly, director of engineering for GM hybrid vehicles and co-executive lead for Challenge X, each team followed a modified version of the GM Global Vehicle Development Process (GVDP) to guide their design and development activities in order to complement the engineering goals of Challenge X. "We gave the students a lot of latitude on what they could do and we also overlaid the competition right on top of GM's GVDP, so we tried to introduce the students to the reality of what it is to design, develop and really almost manufacture a vehicle," Bly says.

In addition to MSU, the other teams participating in the challenge are Michigan Technological University, Ohio State University, Pennsylvania State University, Rose-Hulman Institute of Technology, San Diego State University, Texas Tech University, the University of Akron (Ohio), the University of California, Davis, the University of Michigan, the University of Tennessee, the University of Texas, Austin, the University of Tulsa, the University of Waterloo in Canada, the University of Wisconsin, Madison, Virginia Tech and West Virginia University. MSU tallied 895.5 points out of a 1,000 total points while the runner-up University of Wisconsin, wasn't far behind with 888.3 points. Virginia Tech came in third while Ohio State and Penn State finished fourth and fifth respectively, rounding out the top five.

"The biggest thing I think [the students] get out of it is that they're really given a platform of technologies and support that's pretty much unparalleled," says Forrest Jehlik, Challenge X lead technical coordinator and research engineer for the Advanced Powertrain Research Facility at Argonne National Laboratory which is a competition sponsor. Jehlik, a veteran competitor, took part in the 1997 Propane Vehicle Challenge and the 1998 Ethanol Vehicle Challenge. He was team captain both years for the University of California, Riverside. "They go through a whole series of disciplines to achieve the ultimate goal of putting this vehicle together, and they learned an amazing amount," Jehlik says. "It's just tremendous."

Under the Hood

The teams employed many novel ideas into their designs and technologies that could lead to solutions to reduce well-to-wheel energy consumption, petroleum consumption and tailpipe and GHG emissions, and increase pump-to-wheel fuel economy. All the teams selected hybrid vehicle designs some of which go beyond those being considered by original equipment manufacturers (OEMs). The designs span the scope of parallel through-the-road designs and other hybrid electric vehicle (HEV) series configurations. A parallel through-the-road design is where the biodiesel engine powers the front wheels while the hybrid electric motor powers the back wheels. The electric motor is only used during acceleration periods, and regenerative braking recaptures energy for the electric motor.

During the competition, teams were judged on 19 categories and could earn 1,000 points. The categories ranged from vehicle-handling dynamics to technical presentations where they explain the methodologies they used. The static consumer acceptability event at 90 points, accounted for the most points. "That was probably the one event that put us over the top," Young says. "That was the highest weighted event during the competition."

Twelve of the 17 teams used B20 in their tanks. Three used E85, one used reformulated gasoline and one team used pure hydrogen. "The purpose of the Challenge X competition is to really look at some of the advanced propulsion technologies that can increase fuel efficiency and reduce environmental impact while retaining customer appeal," says Brendan Prebo, manager of OEM outreach education for the National Biodiesel Board (NBB). "If you look at those three things all of those are attributes that biodiesel has."

The MSU team, which took third place in last year's competition, designed a through-the-road parallel electric hybrid Equinox that runs on a 1.9-liter GM direct-injection turbo diesel engine fueled by B20. For the hybrid motor, the team installed a 330-volt Johnson Controls nickel metal hydride battery along with a 45-kilowatt Ballard integrated power transaxle (IPT).

The vehicle achieved a 48 percent increase in fuel economy over the production stock version while attaining a 32 percent reduction in GHG emissions. "All we did was downsize the engine to get better efficiency during a steady driving state and then we supplemented that with an electric drive, which has high efficiencies and very high torques at low speeds and they just complement each other well," says Dave Oglesby, MSU Challenge X team leader and mechanical engineering graduate student. "As a result, you get a vehicle that performs really well. The acceleration and passing capability are really competitive with gas or conventional vehicles, and you have a small engine to propel it down the road in an efficient manner, so you get the best of both worlds."

Seventh-place finisher, the University of Waterloo, which took top honors in the competition's first year, encountered the most daunting task-building a dedicated hydrogen fuel cell for its primary propulsion source. The result was a vehicle with zero emissions from the tailpipe. "I was very impressed with the guys from Waterloo doing a full fuel cell because they took off on a technology that really is in rapid development," Bly says. "They had to implement a system that is not widely available, and they had to engineer a lot of redundancies and safety measures because of the hydrogen on board. They really bit off a ton."

Three teams-Pennsylvania State University, Texas Tech University and the University of Tulsa-used hydrogen as a supplementary or secondary propulsion source. The Penn State team injected hydrogen into their vehicle's diesel engine as an emissions abatement strategy. Texas Tech and Tulsa used hydrogen to power auxiliary systems for their vehicles. The University of California was the only team that used plug-in hybrid technology for an energy source in their Challenge X vehicle.

The University of Michigan team developed a hydraulic hybrid, which stores pressurized fluid in large tanks from which the vehicle can extract or store energy much like an electric hybrid battery stores energy recovered from regenerative braking- a mechanism that reduces vehicle speed by converting some of its kinetic energy into electrical energy. This electrical energy can then be stored for future power demand.

Ohio State and last year's winner, Virginia Tech, used belt alternator/starter technology for an electric performance assist while West Virginia and the University of Akron used ultra-capacitors-electrochemical capacitors that possess high-energy density commonly used in hybrid vehicles-to source high levels of power for short periods of time and still recapture energy from braking. "From a pure refinement point-of-view, I was very impressed with how the teams did with their diesel implementation with the hybrid because they were able to really do a lot of control execution to make it a very pleasing ride," Bly says.

The Future Looks Bright

With results of the third year Challenge X competition in the books, the focus will be directed at preparing for the final event of the competition. In the fourth and final installment of the Challenge X series next year, students will focus on customer acceptability, over-the-road reliability and durability of their advanced propulsion systems with real-world evaluation outside of the laboratory. While some students will remain on the teams, others will take what they learned during the competition and advance their careers in the automotive industry, which will benefit GM and other automotive manufacturers. "I've seen the results of what happens with these students and it's huge," Jehlik says. "The payoff is almost incalculable."

The students who used biodiesel in the competition now know that it is a viable fuel that increases fuel economy and lowers emissions levels. They could go on to establish their unique automotive biodiesel technologies in the automobile industry. "The engineering students that are working on these competitions are absolutely the same students that are going to become the engineers and the program managers for the future technology," Prebo says. "They're learning about diesel engines, hybrid engines and biodiesel now and they're going to take that into their respective employers and really be champions for those technologies. I think that's a real win for biodiesel."

For more information on the Challenge X, visit www.challengex.org.

Bryan Sims is a Biodiesel Magazine staff writer. Reach him at bsims@bbibiofuels.com or (701) 746-8385.

When he first started college he didn't know exactly what to pursue but he was interested in the engineering aspect of automobiles. So he decided to study computer engineering, which led him into designing automotive controls and eventually into a national vehicle design competition.

Young, a graduate student in electrical engineering at Mississippi State University (MSU), finally received the opportunity to put his childhood aspirations into practice when he joined the MSU Center for Advanced Vehicular Systems (CAVS). CAVS is an interdisciplinary center that allows engineering, research, development and technology transfer teams to focus on complex problems, such as those encountered in the technologies designed to improve human mobility.

At CAVS Young, with his background in computer engineering, learned the fundamentals of automotive controls and would later apply that valuable knowledge by participating in the 2007 Challenge X: Crossover to Sustainable Mobility event that was held at the General Motors Corp. (GM) proving grounds in Milford, Mich., May 30-June 7.

MSU placed first out of 17 schools that participated in the four-year competition that started in 2005 and ends in 2008. The teams were challenged to reengineer a GM-donated 2005 Chevrolet Equinox. The goal was to maximize the vehicle's fuel economy, and reduce emissions and greenhouse gases (GHGs) while maintaining or exceeding the vehicle's stock utility and performance. Co-sponsored by the U.S. DOE and GM along with several others, the groundbreaking national event just completed its third year. The sponsors supplied cutting-edge technology and support, including software and hardware components. The first year of the program focused on vehicle simulation, modeling, and subsystem development and testing. In 2006 and 2007, students were able to physically integrate their advanced powertrains and subsystems into the Equinox where they were judged on various categories which were calculated into a point system.

According to Micky Bly, director of engineering for GM hybrid vehicles and co-executive lead for Challenge X, each team followed a modified version of the GM Global Vehicle Development Process (GVDP) to guide their design and development activities in order to complement the engineering goals of Challenge X. "We gave the students a lot of latitude on what they could do and we also overlaid the competition right on top of GM's GVDP, so we tried to introduce the students to the reality of what it is to design, develop and really almost manufacture a vehicle," Bly says.

In addition to MSU, the other teams participating in the challenge are Michigan Technological University, Ohio State University, Pennsylvania State University, Rose-Hulman Institute of Technology, San Diego State University, Texas Tech University, the University of Akron (Ohio), the University of California, Davis, the University of Michigan, the University of Tennessee, the University of Texas, Austin, the University of Tulsa, the University of Waterloo in Canada, the University of Wisconsin, Madison, Virginia Tech and West Virginia University. MSU tallied 895.5 points out of a 1,000 total points while the runner-up University of Wisconsin, wasn't far behind with 888.3 points. Virginia Tech came in third while Ohio State and Penn State finished fourth and fifth respectively, rounding out the top five.

"The biggest thing I think [the students] get out of it is that they're really given a platform of technologies and support that's pretty much unparalleled," says Forrest Jehlik, Challenge X lead technical coordinator and research engineer for the Advanced Powertrain Research Facility at Argonne National Laboratory which is a competition sponsor. Jehlik, a veteran competitor, took part in the 1997 Propane Vehicle Challenge and the 1998 Ethanol Vehicle Challenge. He was team captain both years for the University of California, Riverside. "They go through a whole series of disciplines to achieve the ultimate goal of putting this vehicle together, and they learned an amazing amount," Jehlik says. "It's just tremendous."

Under the Hood

The teams employed many novel ideas into their designs and technologies that could lead to solutions to reduce well-to-wheel energy consumption, petroleum consumption and tailpipe and GHG emissions, and increase pump-to-wheel fuel economy. All the teams selected hybrid vehicle designs some of which go beyond those being considered by original equipment manufacturers (OEMs). The designs span the scope of parallel through-the-road designs and other hybrid electric vehicle (HEV) series configurations. A parallel through-the-road design is where the biodiesel engine powers the front wheels while the hybrid electric motor powers the back wheels. The electric motor is only used during acceleration periods, and regenerative braking recaptures energy for the electric motor.

During the competition, teams were judged on 19 categories and could earn 1,000 points. The categories ranged from vehicle-handling dynamics to technical presentations where they explain the methodologies they used. The static consumer acceptability event at 90 points, accounted for the most points. "That was probably the one event that put us over the top," Young says. "That was the highest weighted event during the competition."

Twelve of the 17 teams used B20 in their tanks. Three used E85, one used reformulated gasoline and one team used pure hydrogen. "The purpose of the Challenge X competition is to really look at some of the advanced propulsion technologies that can increase fuel efficiency and reduce environmental impact while retaining customer appeal," says Brendan Prebo, manager of OEM outreach education for the National Biodiesel Board (NBB). "If you look at those three things all of those are attributes that biodiesel has."

The MSU team, which took third place in last year's competition, designed a through-the-road parallel electric hybrid Equinox that runs on a 1.9-liter GM direct-injection turbo diesel engine fueled by B20. For the hybrid motor, the team installed a 330-volt Johnson Controls nickel metal hydride battery along with a 45-kilowatt Ballard integrated power transaxle (IPT).

The vehicle achieved a 48 percent increase in fuel economy over the production stock version while attaining a 32 percent reduction in GHG emissions. "All we did was downsize the engine to get better efficiency during a steady driving state and then we supplemented that with an electric drive, which has high efficiencies and very high torques at low speeds and they just complement each other well," says Dave Oglesby, MSU Challenge X team leader and mechanical engineering graduate student. "As a result, you get a vehicle that performs really well. The acceleration and passing capability are really competitive with gas or conventional vehicles, and you have a small engine to propel it down the road in an efficient manner, so you get the best of both worlds."

Seventh-place finisher, the University of Waterloo, which took top honors in the competition's first year, encountered the most daunting task-building a dedicated hydrogen fuel cell for its primary propulsion source. The result was a vehicle with zero emissions from the tailpipe. "I was very impressed with the guys from Waterloo doing a full fuel cell because they took off on a technology that really is in rapid development," Bly says. "They had to implement a system that is not widely available, and they had to engineer a lot of redundancies and safety measures because of the hydrogen on board. They really bit off a ton."

Three teams-Pennsylvania State University, Texas Tech University and the University of Tulsa-used hydrogen as a supplementary or secondary propulsion source. The Penn State team injected hydrogen into their vehicle's diesel engine as an emissions abatement strategy. Texas Tech and Tulsa used hydrogen to power auxiliary systems for their vehicles. The University of California was the only team that used plug-in hybrid technology for an energy source in their Challenge X vehicle.

The University of Michigan team developed a hydraulic hybrid, which stores pressurized fluid in large tanks from which the vehicle can extract or store energy much like an electric hybrid battery stores energy recovered from regenerative braking- a mechanism that reduces vehicle speed by converting some of its kinetic energy into electrical energy. This electrical energy can then be stored for future power demand.

Ohio State and last year's winner, Virginia Tech, used belt alternator/starter technology for an electric performance assist while West Virginia and the University of Akron used ultra-capacitors-electrochemical capacitors that possess high-energy density commonly used in hybrid vehicles-to source high levels of power for short periods of time and still recapture energy from braking. "From a pure refinement point-of-view, I was very impressed with how the teams did with their diesel implementation with the hybrid because they were able to really do a lot of control execution to make it a very pleasing ride," Bly says.

The Future Looks Bright

With results of the third year Challenge X competition in the books, the focus will be directed at preparing for the final event of the competition. In the fourth and final installment of the Challenge X series next year, students will focus on customer acceptability, over-the-road reliability and durability of their advanced propulsion systems with real-world evaluation outside of the laboratory. While some students will remain on the teams, others will take what they learned during the competition and advance their careers in the automotive industry, which will benefit GM and other automotive manufacturers. "I've seen the results of what happens with these students and it's huge," Jehlik says. "The payoff is almost incalculable."

The students who used biodiesel in the competition now know that it is a viable fuel that increases fuel economy and lowers emissions levels. They could go on to establish their unique automotive biodiesel technologies in the automobile industry. "The engineering students that are working on these competitions are absolutely the same students that are going to become the engineers and the program managers for the future technology," Prebo says. "They're learning about diesel engines, hybrid engines and biodiesel now and they're going to take that into their respective employers and really be champions for those technologies. I think that's a real win for biodiesel."

For more information on the Challenge X, visit www.challengex.org.

Bryan Sims is a Biodiesel Magazine staff writer. Reach him at bsims@bbibiofuels.com or (701) 746-8385.

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events