Decarbonizing Process Heat: The Key to Capturing Once-In-A-Generation Incentives

May 11, 2023

BY Jordan Kearns

The Renewable Fuel Standard led to massive investment across the ethanol industry. Producers seized on the opportunity, built new plants, and saw profits that enabled unprecedented payback periods. Those who acted quickly were able to use the incentive to pay off their assets, putting them in a strong financial position for growth.

Today, the industry has an opportunity at a scale not seen since the RFS passed a generation ago; low-carbon fuel incentives representing hundreds of millions of dollars are on the table through the Clean Fuel Production Tax Credit, commonly known as 45Z.

There’s been significant progress in the industry on carbon capture, driven by 45Q. But there’s now another opportunity that’s just as big: decarbonizing process heat to take advantage of the new 45Z credit. Abundant wind energy throughout the Corn Belt gives producers a low-cost source of clean energy, but its intermittency makes it difficult to put to use. New solutions like thermal energy storage harness this variable resource to fit the round-the-clock heat needs of ethanol producers, unlocking this once-in-a-generation tax credit.

How 45Z Works: Incentives Favor Early Movers

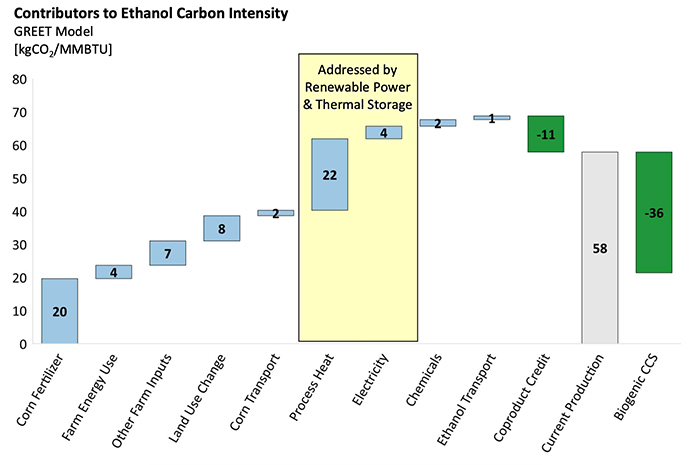

45Z gives producers a tax credit for every gallon of fuel produced, which increases as the carbon intensity (CI) of the fuel decreases. Under the 45Z program, producers begin qualifying for credits at CI scores below 50 kgCO2e/MMBtu—using an accounting mechanism that is more favorable to ethanol producers than California’s LCFS standards.

For every point of CI reduction below this threshold, tax credits increase by $0.02 per gallon, such that zero-carbon fuel would qualify for a credit of $1 per gallon. This incentive represents the equivalent of about $250 per ton of carbon abated—three times the incentive for carbon sequestration in Section 45Q.

This is a massive opportunity for ethanol plants: 25 points of carbon intensity reduction for a 100 MMgy plant would result in $50 million of annual, transferable tax credits from 45Z. But while the opportunity is large, the window is limited: the program is currently only authorized for fuel produced in 2025, 2026 and 2027. An extension is always possible, but as this industry knows, it is never certain.

Just like with the RFS, early movers that invest in decarbonization will reap the benefits, quickly paying off their capital investment within the three years 45Z is currently authorized. And even after the provision sunsets, plants that seized this decarbonization opportunity will continue to benefit from lower energy costs and a differentiated, low-carbon product.

Two Main Paths to Reduce CI of Ethanol Plants

Producers have dozens of levers to reduce the carbon intensity of their product, from partnering with farmers on sustainable growing practices to tapping into efficient supply chains that minimize transportation emissions. But when it comes to moving the needle in a major way, there are only two potential targets: capturing the biogenic carbon from fermentation, and decarbonizing process energy. Carbon capture has the potential to lower the carbon intensity of ethanol plants by 30 points (after accounting for the increased power load), and producers are already seizing upon this reduction potential.

Process energy is an opportunity that’s just as big, but the industry’s current focus on energy efficiency retrofits can only move the needle a little. While energy efficiency is an important tool, its impact is inherently limited—a plant can only be so efficient. Fully decarbonizing process heat has the potential to tackle the entire problem at once, lowering carbon intensity by 20 to 25 points. Decarbonizing power offers another 4 to 5 points of reduction (and even more for plants installing CO2 compressors).

To fully realize the benefit of 45Z, producers will have to change their primary fuel source—eliminating fossil fuel combustion altogether. Fortunately, the ethanol industry has the lowest-cost source of zero-carbon energy on its doorstep: our nation’s growing fleet of wind farms.

The Ethanol Industry's Wind Power Opportunity

Wind power could not be better located for ethanol producers. Two-thirds of ethanol production capacity is located within 25 miles of a wind farm, and almost 90% is within 50 miles.

Wind power is not only affordable, but a potentially lower-cost source of energy than incumbent fuels including natural gas. The law of supply conspires to keep the price of wind power low. Weather formations extend over hundreds of miles, meaning if a wind farm is having a windy, high-production day in Iowa, so too are all the wind farms between Iowa and Kansas. This simultaneous surge of supply sends power prices crashing precisely when the wind is most productive. In the windiest parts of the country, one-third of the energy produced by wind farms can have a market value of zero. Even negatively priced power has become increasingly common.

While this low-cost power is a major problem for wind producers, it opens a major opportunity for energy users. But to harness it, we need to bridge this intermittent resource with continuous ethanol production.

Thermal Energy Storage: Best Path to Decarbonizing Process Energy

Thermal energy storage takes variable clean electricity and converts it into dispatchable process heat. The operation of a “thermal battery” is simple: a safe and stable material is electrically heated in an insulated container, storing that intermittently available, low-value electricity as high-grade heat for hours or even days (our company, Antora Energy, uses carbon blocks, which are cost-effective, domestically produced, and capable of reaching temperatures over 4,000 degrees F—hotter than a natural gas burner). Energy is then extracted from this heat reservoir as steam or hot air when needed, integrating into existing processes as a drop-in replacement or supplement to natural gas boilers or other heating equipment.

Thermal energy storage is a simple, “low-tech” solution that combines decades-old technologies found commonly in other industrial processes to capture the dual opportunities of cheap renewable energy and industrial decarbonization. Companies such as Antora have reconfigured these systems to integrate into existing industrial processes, enabling producers to decarbonize using proven technologies.

A Chance to Set Ethanol Plants Up for the Future

With a limited window to capture the huge upside of 45Z, ethanol producers must move quickly to decarbonize. The potential upside is huge: thermal energy storage projects can achieve full payback within two years. Innovative producers that take advantage of the credit will pay off the capital invested to decarbonize within the 45Z credit period, and then continue to benefit from lower operating costs and lower emissions for the 30-plus year lifespan of these projects. Producers that take a wait-and-see approach, on the other hand, will have to compete with these early adopters that have already paid off their capital and are enjoying the benefits of lower operating costs and the higher margins of a lower-carbon product.

The technologies that will enable producers to reduce the carbon intensity of ethanol production, from carbon capture to process heat, are already here. They’re proven on the ground and easy to integrate into existing facilities. The clock is ticking to deploy them in time to capture every dollar of this once-in-a-generation credit.

Author: Jordan Kearns

Vice President of Project Development

Antora Energy

jordan.kearns@antora.energy

Printed in the 2023 June issue of Ethanol Producer Magazine

Advertisement

CONTRIBUTION: The claims and statements made in this article belong exclusively to the author(s) and do not necessarily reflect the views of Ethanol Producer Magazine or its advertisers. All questions pertaining to this article should be directed to the author(s).

Advertisement

Upcoming Events