Efficient Ethanol Production

February 9, 2010

BY Karsten Deuringer and Sven Fleischer

Ethanol production is a very old and rather simple process. You just add yeast to a sugar solution and the process begins. But is it really so simple?

Much research to define the correct sugar concentration has been carried out lately. A lot of subsidies have been allocated and a lot of engineering capacity has been employed worldwide to attain the latest and most up-to-date information.

There has also been much discussion recently on the splitting of the base material and the preparation of sugar solutions. The fermentation process and yeast handling is accepted as a given, but is, in fact, the heart of ethanol production.

Efficient ethanol production is crucial for industrial companies if they wish to facilitate a minimum of production costs and at the same time enable a maximum ethanol yield. This is particularly important when ethanol is produced for fuel purposes.

Yeast Conditions

Fermentation is based on yeast, a living fungi. This crucial factor distinguishes ethanol distilleries from other chemical industries. When working with a living organism and relying upon its productivity, it is essential that plant operators ensure a hygienic environment to allow the fungi to thrive.

An important aspect of ethanol production is ensuring byproducts such as glycerol are kept at a minimum.

The yeast variety used for ethanol production is the most productive of the yeast family. The ethanol process requires yeast to adapt rapidly from an aerobic to an anaerobic environment and back. Yeast uses glucose to produce a high yield of ethanol, provided the environment is ideal.

To avoid the yeast being exposed to extreme concentrations of sugar, glucose levels must be kept at an optimal level. Proper nutrition such as an optimal free amino nitrogen level helps to maintain the essential vitality and necessary conditions for optimal ethanol production in a fermenter tank.

As with every living organism, yeast fungi can be affected by external factors. High organic acid and sodium levels, bacteria pollution of the culture medium or pollution with wild yeast varieties impair the yeast. If a solution is polluted for any reason, external stressors start competing for glucose and can cause a reduction in the ethanol yield.

Processing parameters such as pH, temperature and the degradation rate of available sugar need to be monitored to maintain an optimal substrate for fermentation. For example, a too-high or too-low pH will force the yeast to use valuable energy to balance its own internal pH while not maximizing productivity. High operating temperatures will cause the yeast to die. Low temperatures restrain the yeast and can make it inert. Hence, without active yeast, sugars will not be converted into ethanol and the potential for contamination grows as the sugar is available for other organisms.

Proper design of the fermentation process, permanent monitoring and meticulous plant hygiene, careful yeast handling and maintenance as well as efficient cooling equipment are therefore essential for successful ethanol production.

Critical Production Factors

Critical processing issues are slow fermentation and high residual starches that contribute to a low yield. There are several potential sources of error and sources of hygienic problems that have to be considered. For example, it is necessary to distinguish between problems caused by the characteristics of the sugar solution and yeast, physical production conditions and plant maintenance.

The filling of a fermenter must commence at a specific time. A monitored filling cycle and any noted corrections during the cycle help to define mistakes and the time at which they occurred in one charge. Production problems can be caused by solutions having a higher organic acid peak (lactic, acetic or succinic) than others in the same plant (see yeast conditions above). Furthermore, the design of the plant, especially the fermentation unit, is decisive for preventing infections. For example, foam in the fermenting matter can enter by way of the CO2 exhaust pipes and generate a perfect habitat for all kinds of germs, which could then re-infect the next filling of the fermenter. Plant hygiene is vital to avoid contamination by wild yeasts and bacteria. As suggested earlier, infected pipes or vessels allow pathogenic germs to vie with the yeast for sugar.

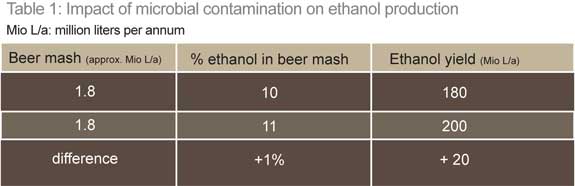

To illustrate the impact of microbial contamination, consider a distillery processing 1.8 million litres (475,000 gallons) of beer mash annually. An increase in ethanol concentration in the beer mash from 10 percent to 11 percent as a result of less contamination is likely to increase the ethanol production by 20 million liters (table 1). At current ethanol prices, this amounts to a potential win of some €10 million ($14.15 million) (FO Licht's World Ethanol Price Report (2010) January 11, 5 (37): 1).

Logical and Systematic Problem Reduction

Proper documentation of operating conditions is essential for troubleshooting. Without precisely documented log sheets and records, it is unlikely that the cause of any problems will be found. Installing reliable measuring equipment in essential places helps avoid and detect errors.

Although the first step is a thorough design and adequate yeast management and fermentation, an exceedingly high level of plant hygiene is absolutely necessary. Even today you can still find blind pipes where cleaning is impossible. Additionally, all surfaces need to be smooth and free of any dents and scratches. One of the undesirables for yeast is lactobacillus bacteria. These bacteria are 0.9 x 2 microns in size. By manufacturing a surface smoothness of less than 1.0 micron variation, possible pockets for bacteria are avoided. Additionally, cleaning is much more efficient and interrupted production cycles are reduced to a minimum.

Ziemann Design and Production Standards

Ziemann has been working in the brewing industry for more than 150 years and has gained a wealth of experience in beer fermentation. As a leading manufacturer of approximately 400 fermenters a year, Ziemann continually incorporates this knowledge into the design of fermenter tanks.

The company uses cold rolled stainless steel at its production sites. It is handled with maximum care and worked to highest standards. Steel sheets are covered with a protective plastic foil before and after grinding and for all transportation. Lifting devices are equipped with suction cups to prevent any scratching and denting. Welding and grinding procedures have been perfected over the years. Ziemann workshops grind with grid 80 to 120 to achieve flawless surfaces employing machinery with adaptable grinding shape and pressure.

High Level of Plant Hygiene

At present, numerous ethanol plants still utilize simple flat tanks with critical surface conditions and rough welds. Settling of pathogenic germs can hardly be avoided inside these tanks. Furthermore, serious hazards emerge from external loops to the heat exchanger for dissipating surplus heat produced by the fermentation process. Two challenges have to be faced: keeping hygiene at a maximum, especially in plate heat exchangers and pumps, and at the same time, maintaining an optimal overall beer mash temperature to ensure maximum production.

Integrating the latest knowledge and scientific results into modern design of ethanol production can keep potential sources of infection at a minimum. At the same time, subtle shapes facilitate easy cleaning of the equipment. A good example is the cooling system of the tank.

Over the past century, the brewing industry has considerably improved cooling systems. Today, Ziemann not only implements this valuable knowledge in the brewing sector but also applies it to other tank systems. The Ziemann Group builds tanks with direct cooling systems inside the tank walls. Additionally, dimpled jackets and segment pipes are used for various cooling media such as water, glycol or ammonia. An ammonia cooling system has proven to be the most efficient system. Inside the tank's shell ammonia evaporates and thus constantly absorbs heat.

Avoiding Agitators

Using agitators to circulate the beer mash is common practice in ethanol production. These types of agitators include centered agitators with counter baffles, two agitators installed at the bottom of the tanks and positioned in an upward angle, agitators without baffles and small stirrers positioned on the wall of the tanks. Ziemann completely avoids using agitators by taking advantage of the physical effect of hot and cold zones in the tank. In a narrow tank with shell cooling it is possible to achieve a natural circulation of the beer mash with the convection center of 33 degrees Celsius rising in the middle of the tank and flowing along the tank walls at a lower temperature—an intelligent design that not only avoids mechanical installations inside the tank but also reduces energy consumption and keeps hygienic hazards to a minimum.

To achieve maximum ethanol yield, it is essential to provide optimal conditions for yeast combined with impeccable plant hygiene. A smart layout and clever plant design meet these requirements, especially in the design of fermenter tanks and the implementation of monitoring equipment in all essential areas. EP

Karsten Deuringer is in sales, ethanol project planning, and Sven Fleischer is a process engineer at Ziemann Energy Gmbh. Reach them at energy@ziemann.com.

Much research to define the correct sugar concentration has been carried out lately. A lot of subsidies have been allocated and a lot of engineering capacity has been employed worldwide to attain the latest and most up-to-date information.

There has also been much discussion recently on the splitting of the base material and the preparation of sugar solutions. The fermentation process and yeast handling is accepted as a given, but is, in fact, the heart of ethanol production.

Efficient ethanol production is crucial for industrial companies if they wish to facilitate a minimum of production costs and at the same time enable a maximum ethanol yield. This is particularly important when ethanol is produced for fuel purposes.

Yeast Conditions

Fermentation is based on yeast, a living fungi. This crucial factor distinguishes ethanol distilleries from other chemical industries. When working with a living organism and relying upon its productivity, it is essential that plant operators ensure a hygienic environment to allow the fungi to thrive.

An important aspect of ethanol production is ensuring byproducts such as glycerol are kept at a minimum.

The yeast variety used for ethanol production is the most productive of the yeast family. The ethanol process requires yeast to adapt rapidly from an aerobic to an anaerobic environment and back. Yeast uses glucose to produce a high yield of ethanol, provided the environment is ideal.

To avoid the yeast being exposed to extreme concentrations of sugar, glucose levels must be kept at an optimal level. Proper nutrition such as an optimal free amino nitrogen level helps to maintain the essential vitality and necessary conditions for optimal ethanol production in a fermenter tank.

As with every living organism, yeast fungi can be affected by external factors. High organic acid and sodium levels, bacteria pollution of the culture medium or pollution with wild yeast varieties impair the yeast. If a solution is polluted for any reason, external stressors start competing for glucose and can cause a reduction in the ethanol yield.

Processing parameters such as pH, temperature and the degradation rate of available sugar need to be monitored to maintain an optimal substrate for fermentation. For example, a too-high or too-low pH will force the yeast to use valuable energy to balance its own internal pH while not maximizing productivity. High operating temperatures will cause the yeast to die. Low temperatures restrain the yeast and can make it inert. Hence, without active yeast, sugars will not be converted into ethanol and the potential for contamination grows as the sugar is available for other organisms.

Proper design of the fermentation process, permanent monitoring and meticulous plant hygiene, careful yeast handling and maintenance as well as efficient cooling equipment are therefore essential for successful ethanol production.

Critical Production Factors

Critical processing issues are slow fermentation and high residual starches that contribute to a low yield. There are several potential sources of error and sources of hygienic problems that have to be considered. For example, it is necessary to distinguish between problems caused by the characteristics of the sugar solution and yeast, physical production conditions and plant maintenance.

The filling of a fermenter must commence at a specific time. A monitored filling cycle and any noted corrections during the cycle help to define mistakes and the time at which they occurred in one charge. Production problems can be caused by solutions having a higher organic acid peak (lactic, acetic or succinic) than others in the same plant (see yeast conditions above). Furthermore, the design of the plant, especially the fermentation unit, is decisive for preventing infections. For example, foam in the fermenting matter can enter by way of the CO2 exhaust pipes and generate a perfect habitat for all kinds of germs, which could then re-infect the next filling of the fermenter. Plant hygiene is vital to avoid contamination by wild yeasts and bacteria. As suggested earlier, infected pipes or vessels allow pathogenic germs to vie with the yeast for sugar.

To illustrate the impact of microbial contamination, consider a distillery processing 1.8 million litres (475,000 gallons) of beer mash annually. An increase in ethanol concentration in the beer mash from 10 percent to 11 percent as a result of less contamination is likely to increase the ethanol production by 20 million liters (table 1). At current ethanol prices, this amounts to a potential win of some €10 million ($14.15 million) (FO Licht's World Ethanol Price Report (2010) January 11, 5 (37): 1).

Logical and Systematic Problem Reduction

Proper documentation of operating conditions is essential for troubleshooting. Without precisely documented log sheets and records, it is unlikely that the cause of any problems will be found. Installing reliable measuring equipment in essential places helps avoid and detect errors.

Although the first step is a thorough design and adequate yeast management and fermentation, an exceedingly high level of plant hygiene is absolutely necessary. Even today you can still find blind pipes where cleaning is impossible. Additionally, all surfaces need to be smooth and free of any dents and scratches. One of the undesirables for yeast is lactobacillus bacteria. These bacteria are 0.9 x 2 microns in size. By manufacturing a surface smoothness of less than 1.0 micron variation, possible pockets for bacteria are avoided. Additionally, cleaning is much more efficient and interrupted production cycles are reduced to a minimum.

Ziemann Design and Production Standards

Ziemann has been working in the brewing industry for more than 150 years and has gained a wealth of experience in beer fermentation. As a leading manufacturer of approximately 400 fermenters a year, Ziemann continually incorporates this knowledge into the design of fermenter tanks.

The company uses cold rolled stainless steel at its production sites. It is handled with maximum care and worked to highest standards. Steel sheets are covered with a protective plastic foil before and after grinding and for all transportation. Lifting devices are equipped with suction cups to prevent any scratching and denting. Welding and grinding procedures have been perfected over the years. Ziemann workshops grind with grid 80 to 120 to achieve flawless surfaces employing machinery with adaptable grinding shape and pressure.

High Level of Plant Hygiene

At present, numerous ethanol plants still utilize simple flat tanks with critical surface conditions and rough welds. Settling of pathogenic germs can hardly be avoided inside these tanks. Furthermore, serious hazards emerge from external loops to the heat exchanger for dissipating surplus heat produced by the fermentation process. Two challenges have to be faced: keeping hygiene at a maximum, especially in plate heat exchangers and pumps, and at the same time, maintaining an optimal overall beer mash temperature to ensure maximum production.

Integrating the latest knowledge and scientific results into modern design of ethanol production can keep potential sources of infection at a minimum. At the same time, subtle shapes facilitate easy cleaning of the equipment. A good example is the cooling system of the tank.

Over the past century, the brewing industry has considerably improved cooling systems. Today, Ziemann not only implements this valuable knowledge in the brewing sector but also applies it to other tank systems. The Ziemann Group builds tanks with direct cooling systems inside the tank walls. Additionally, dimpled jackets and segment pipes are used for various cooling media such as water, glycol or ammonia. An ammonia cooling system has proven to be the most efficient system. Inside the tank's shell ammonia evaporates and thus constantly absorbs heat.

Avoiding Agitators

Using agitators to circulate the beer mash is common practice in ethanol production. These types of agitators include centered agitators with counter baffles, two agitators installed at the bottom of the tanks and positioned in an upward angle, agitators without baffles and small stirrers positioned on the wall of the tanks. Ziemann completely avoids using agitators by taking advantage of the physical effect of hot and cold zones in the tank. In a narrow tank with shell cooling it is possible to achieve a natural circulation of the beer mash with the convection center of 33 degrees Celsius rising in the middle of the tank and flowing along the tank walls at a lower temperature—an intelligent design that not only avoids mechanical installations inside the tank but also reduces energy consumption and keeps hygienic hazards to a minimum.

To achieve maximum ethanol yield, it is essential to provide optimal conditions for yeast combined with impeccable plant hygiene. A smart layout and clever plant design meet these requirements, especially in the design of fermenter tanks and the implementation of monitoring equipment in all essential areas. EP

Karsten Deuringer is in sales, ethanol project planning, and Sven Fleischer is a process engineer at Ziemann Energy Gmbh. Reach them at energy@ziemann.com.

Advertisement

Advertisement

Advertisement

Advertisement

Upcoming Events