Joint venture to commercialize biomass processing technology

SOURCE: BEE

September 15, 2015

BY Anna Simet

Active Energy Group plc, a global supplier of wood fiber products for MDF manufacturing, and processing system supplier Biomass for Energy have announced a joint venture wherein the companies will work with Utah-based Biomass Energy Enhancements LLC on commercializing a pretreatment technology that BEE says enables biomass to be utilized as a direct replacement for coal or for cofiring, without requiring steep investments plant modifications.

Called AEG Coalswitch Ltd, the joint venture will hold global intellectual property rights for the fuel manufacturing process for which sixteen patent applications have been filed, according to a news release issued by majority stakeholder Active Energy Group.

The companies describe the technology as a “groundbreaking biomass fuel processing system” that has been in development for seven years and “has potential to be a game changer for the industry.”

Advertisement

Although it yeilds a product with comparable energy content, the technology is not torrefaction, said BEE Chief Technology Officer Philip Scalzo. "Torrefaction is an entirely thermal process where volatiles are removed either partially or completely through combustion by heating the biomass the biomass in a low oxygen envirnoment. The combustion of the volatiles provides the necessary heat to maintain the process. The end product of torrefaction will have a higher energy content than its parent feedstock because the volatiles removed have lower energy content than the remaining carbon. Torrefaction does not remove ash or mineral/salt contamination. It does remove entrained moisture through evaporation."

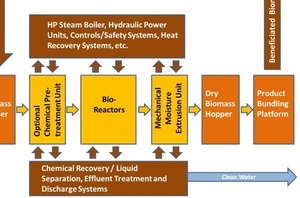

The BEE process, Scalzo said, is a physiochemical process that removes light- and medium-weight volatiles from the parent biomass feedstock along with almost all mineral and salt contamination. "Interstitial and process water is mostly removed through mechanical extrusion rather than through evaporation.

"The BEE process can utilize low quality, inexpensive feedstock to produce a coal substitute because it largely removes contamination. Torrefaction must use higher quality, typically expensive feedstock to produce a coal substitute that can be burned in conventional coal plants."

The finished fuel can be delivered in a range of different compacted formats including pellets, granules, briquettes or bales and contains similar thermal and friability characteristics to coal, according to BEE.

Advertisement

The joint venture said it has already commenced negotiations with leading investment funds to raise the capital required to roll out its ‘build-own-operate-toll’ business model, under which the company intends to construct a network of advanced demountable fuel manufacturing facilities near large-scale biomass raw material sources.

AEG CoalSwitch intends to partner with coal-fired power station owners and operators across the globe and said several have already shown great interest in the concept. In statements announcing the JV, Richard Spinks, CEO of Active Energy Group said the partnership represents a revolution for the industry and for the environment. “And the timing is perfect –just weeks after President Obama’s landmark speech setting stringent emissions reductions targets on U.S. energy producers and piling the pressure on them to clean up or shut down, and just days after the owners of the Eggborough coal-fired power plant in Yorkshire announced that they would be closing the 2,000 MW facility in March 2016 , with the loss of 250 local jobs and 4 percent of the U.K.’s electricity generation capacity, due to the lack of government funding required to convert it from coal to traditional Biomass fuel operation. ”

Spinks added that AEG CoalSwitch is aiming to have a market-ready product by mid-2016.

Upcoming Events