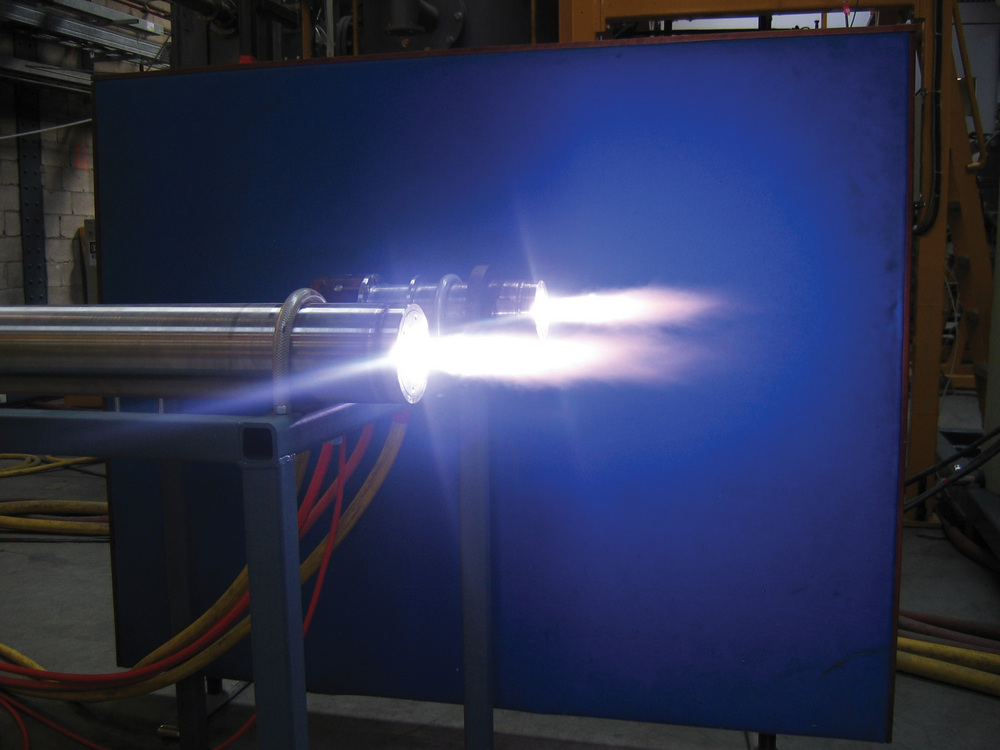

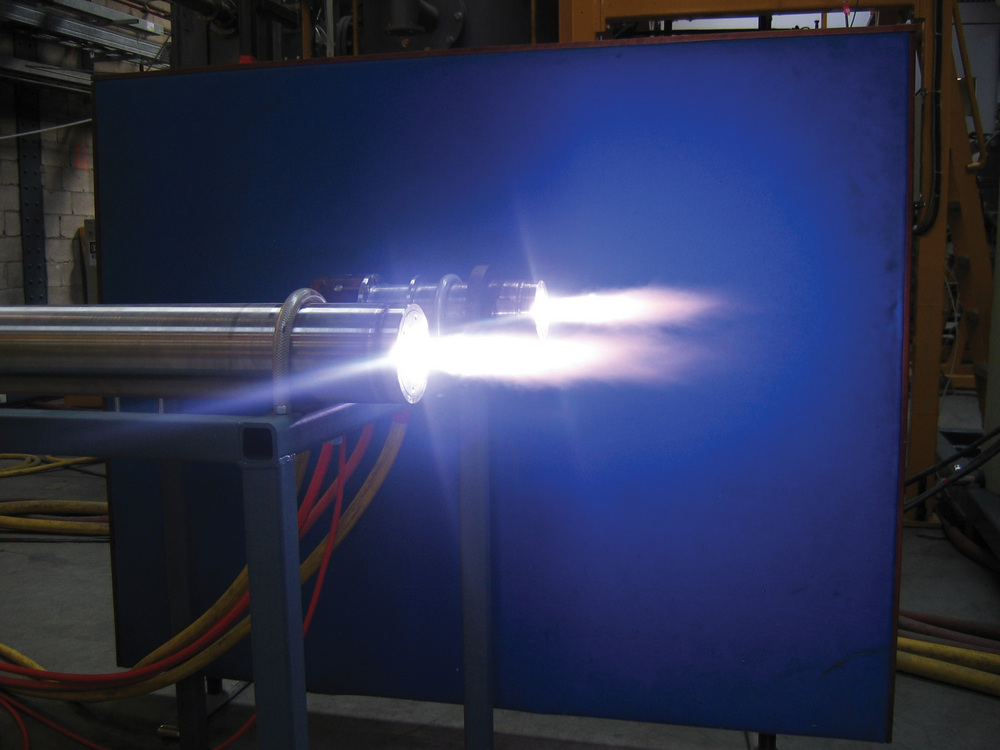

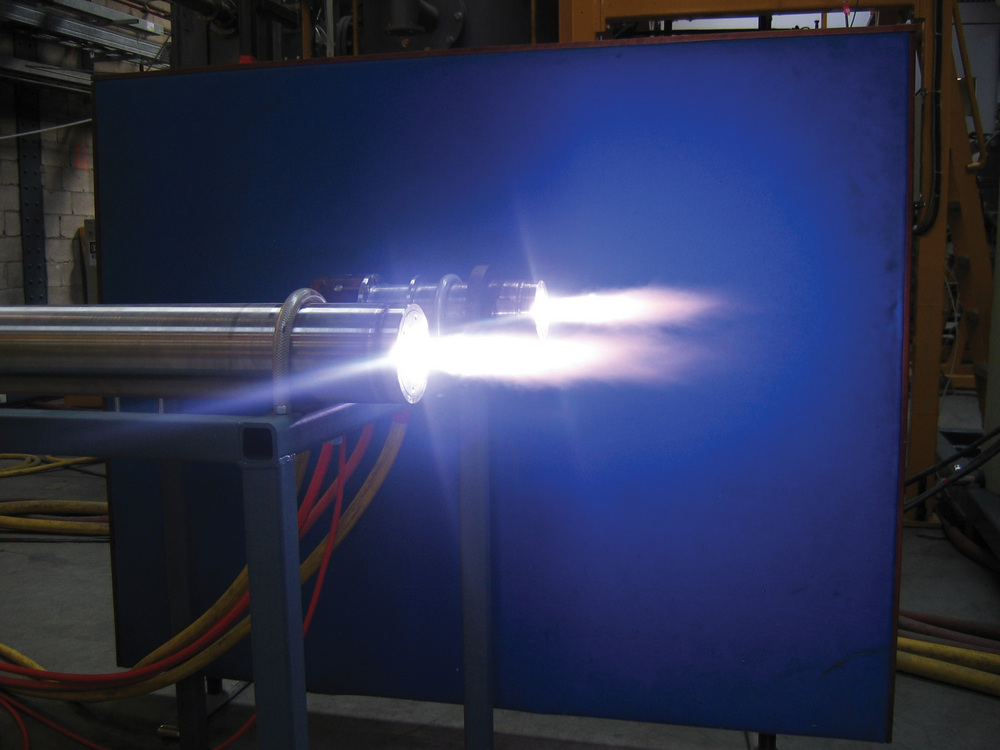

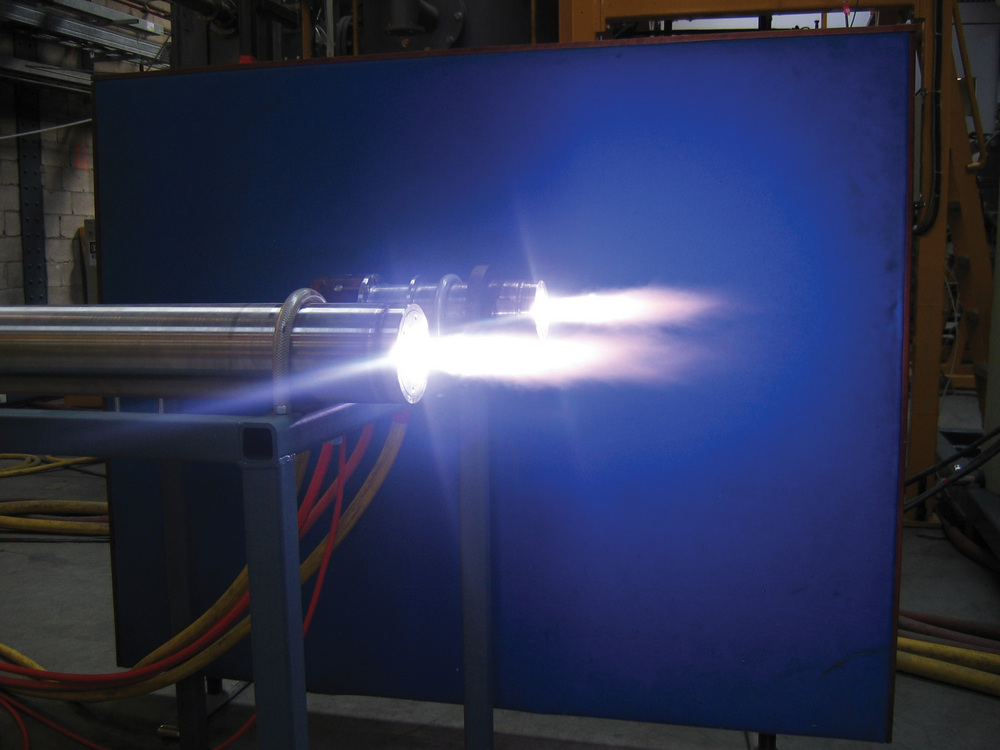

Pyrogenesis Perfecting Plasma

PHOTO: PYROGENESIS CANADA INC.

August 23, 2011

BY Lisa Gibson

Since late last year, the U.S. Air Force Special Operations Command in Hurlburt Field, Fla., has been generating energy from municipal solid waste (MSW) in lieu of landfilling, using a 10.5 metric-ton-per-day plasma gasification process.

The system is small, but represents the first commercial installation of the technology for developer and vendor Quebec-based Pyrogenesis Canada Inc. “It is a showcase for them, as well as a showcase for us,” says Tom Whitton, business development leader for the company.

The MSW feedstock will be sourced from Hurlburt, but the system will also use some industrial, medical and hazardous waste from nearby Eglin Air Force Base, Whitton says. The 400 to 500 kilowatts it will produce is enough to power itself, with no surplus for sale to utilities. Pyrogenesis, does, however, have systems available up to 100 metric tons per day, which would allow for excess power sales.

Advertisement

The two-step plasma gasification system includes a furnace with graphite electrodes that operates at 1,600 degrees Celsius (2,912 degrees Fahrenheit) to create the plasma, Whitton explains. In the furnace, all inorganic materials are converted to vitrified slag that can be mixed with cement or asphalt and used in construction, while the organics begin partial gasification. The gas created in the furnace goes directly through the plume of a plasma torch, producing the syngas that is then cleaned. “What we’re doing in Florida is we’re actually feeding that gas, once it’s been completely cleaned up … into an internal combustion engine to produce electricity,” Whitton says.

One of the advantages of using thermal plasma in the gasification process, he adds, is that it can handle a high variation of feedstock with its temperatures in excess of 10,000 degrees Celsius. “Because of the extreme temperatures that plasma operates in, virtually no chemical substances or compounds can survive that.”

The cost to build the plant was $7.4 million, funded by the U.S. Foreign Comparative Testing Office, Air Force Smart Operations for the 21st Century, the Canadian government, the U.S. Air Force Surgeon General's office, and Gulf Power. While Pyrogenesis is a vendor and does not typically operate its technology when installed, the company is operating the Hurlburt Field plant through a contract with the Air Force, Whitton says.

Advertisement

The system is perfectly suited for the Air Force because it is transportable and designed for “plug and play,” Whitton says. It can be disassembled, moved and reassembled easily. “They work as an island,” he says of Air Force bases, adding that self-sufficiency is crucial.

"This is history in the making," Terry Yonkers, assistant secretary of the Air Force for installations, environment and logistics, said at a ribbon-cutting ceremony for the plant in April. "This is the first waste-to-energy project of this technology to go into an air base. It has been a long time in the making." For the base, it will mean diverting nearly 8.3 tons of daily domestic trash from landfills, reducing gas emissions by over 83,000 tons per year and eliminating toxic materials while producing energy.

“It’s much more of a waste management project than an energy project,” Whitton says. “But without the energy recovery, it wouldn’t fly.”

—Lisa Gibson

Upcoming Events