'State of Green' Embraces Pellet Power

June 23, 2014

BY Lennart Ljungblom

The first two ships loaded with U.S. pellets slipped into Denmark’s port this past year. What are the prospects that Denmark’s power industry will join the United Kingdom’s in turning to the United States to fill its growing demand for biomass-based power and heat?

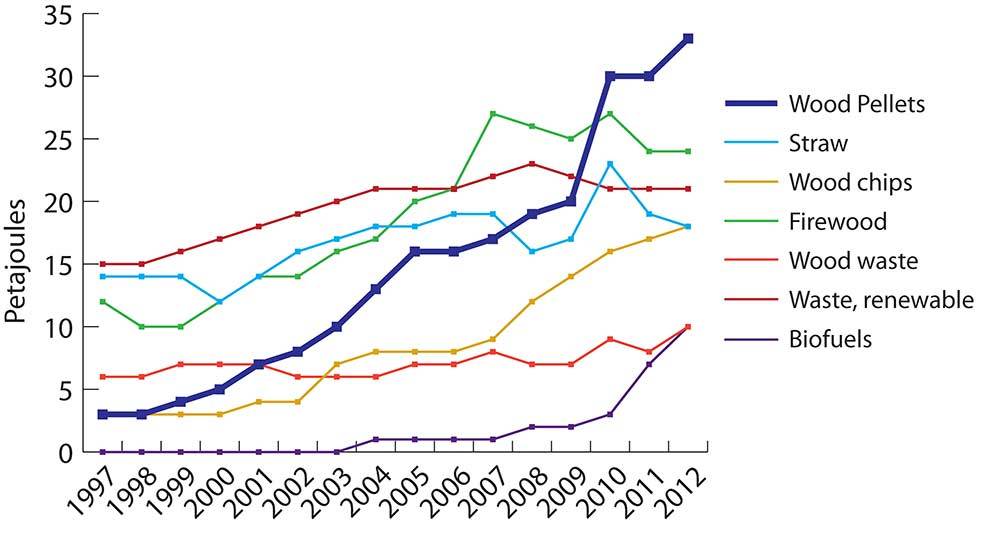

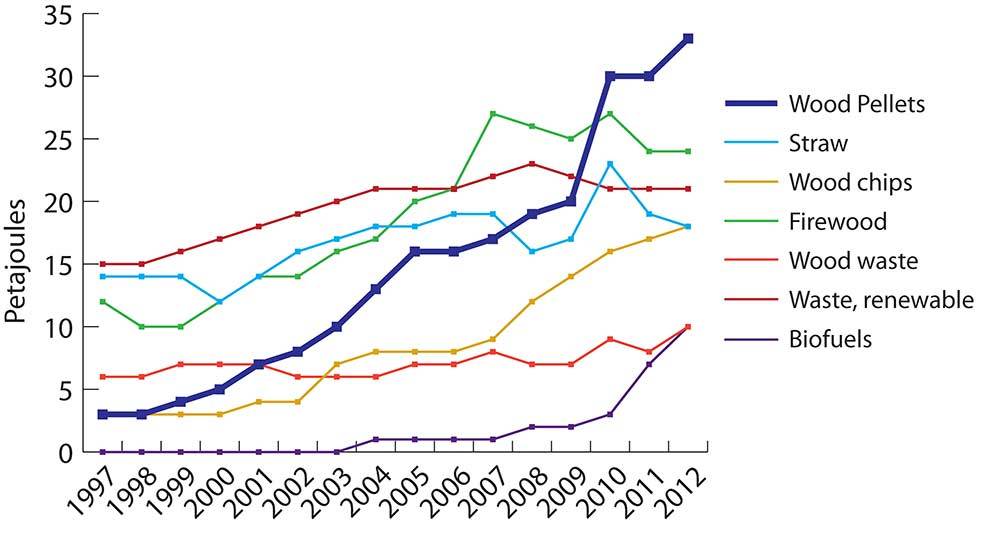

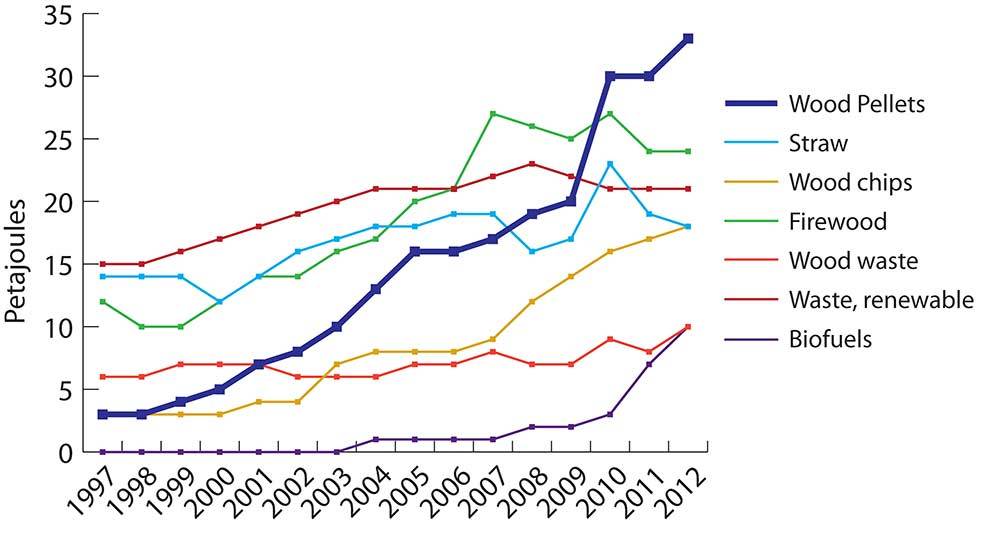

Denmark is moving ahead toward its goal of minimizing fossil fuels. For many years, pellets, wood chips and straw have been used in heat and power plants as well as in medium-sized industrial boilers and private homes. The only large domestic biomass resource is straw and most wood chips and wood pellets are imported. In 2012, Denmark used around 1.9 million metric tons of pellets—a figure expected to increase by another 1 million tons of mostly industrial quality during the coming three years. Some of the announced big coal-to-gas conversion projects will not choose pellets, but are expected to go for wood chips.

Denmark is a small country, the size of West Virginia, with 5.5 million people, a population much like Maryland. The Copenhagen metropolitan area holds around 2 million inhabitants. By tradition, agriculture is important in Denmark, but the country also holds an important position in the renewable industry with several leading manufacturers.

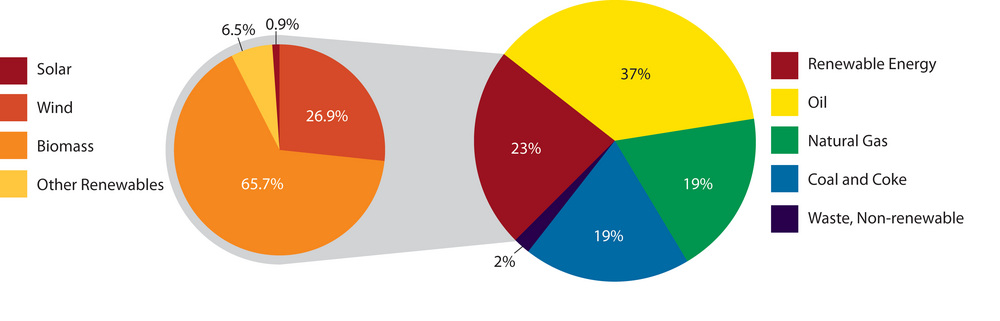

The country’s highly developed and efficient energy sector is based on combined-heat-and-power (CHP) systems wherever possible, plus about 60 percent of the population is served by district heat. One must remember, however, that Denmark also is a gas- and oil- producing country. Every day, 100,000 barrels of oil-equivalent gas and oil production from the North Sea are landed, and natural gas is used for heat.

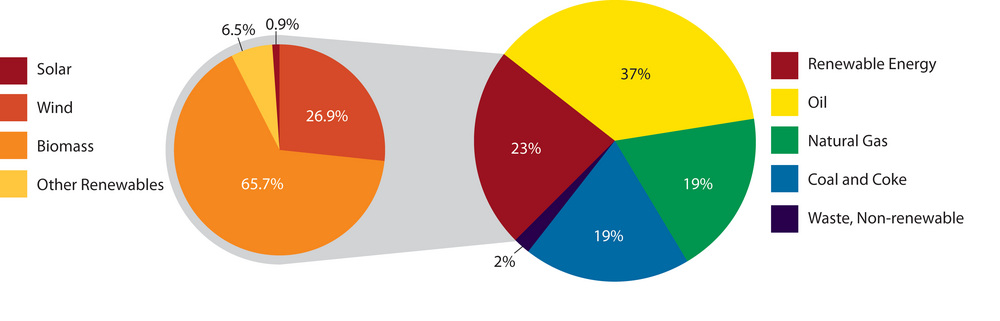

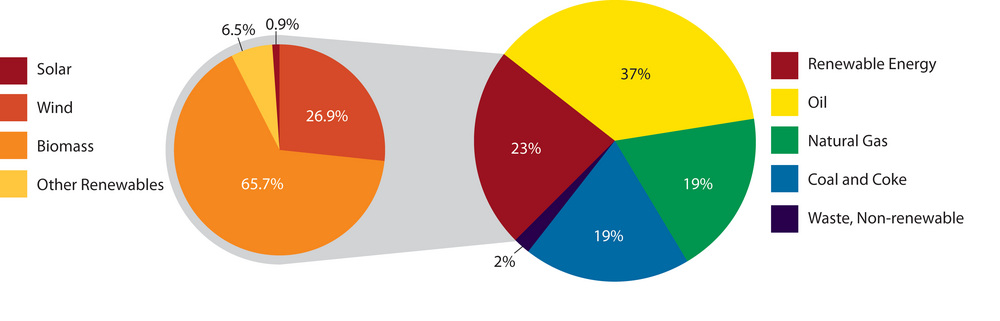

Denmark has accepted the goal of limiting global heating to 2 degrees Celsius, and despite its own oil production, is replacing oil, coal and gas with biomass, adopting the slogan “State of Green.” In 2012, 52 percent of Danish district heat was supplied by woody biomass, with the goal of reaching 100 percent by 2035.

Sustainability is very important in Denmark, with an ongoing debate about the degree of sustainability of imported wood pellets. When the attempt to develop a common biomass standard for the European Union was not successful, industry adopted its own. Several large EU importers formed the Sustainable Biomass Partnership, including Dong, Vattenfall and Drax. All large utilities are not within the SBP, however, and Eon, GDF Suez, Eggborough and RWE, say they will launch a sustainable biomass standard and certificate in 2014. Parts of the emerging sustainability standards are not controversial, including the approach to ensure full transparency and the use of existing global forest management schemes from the Forest Stewardship Council and the Program for the Endorsement of Forest Certification. Regulations regarding the use of different types of forest land and virgin forests, however, are most controversial.

The energy market in Denmark is regulated. Development is driven by a framework of CO2 quotas, taxes and pricing structures for heat and electricity. At present, all political bits and pieces are not fully in place, so some of the announced big biomass conversion projects are still in limbo, waiting for the final go-ahead. A suggested new tax on biomass was dropped as late as April 4, indicating a solution may be on the way.

Roughly 4 percent of Denmark’s total energy consumption is supplied in wood pellets. The market is well-developed and wood pellets are widely used, in everything from small boilers and stoves in private homes to large CHP plants. Consumption of wood pellets increased five-fold between 2001 and 2012, bringing total Danish consumption above 1.9 million metric tons in 2012. The rise is largely attributed to increased use in large facilities, which in 2012 used approximately 1.3 million metric tons of wood pellets, replacing nearly 1 million metric tons of coal.

Advertisement

Advertisement

Power And Heat Today

Two existing power plants and one under construction provide heat for the Copenhagen district heat system and electricity to the Nordic grid. The largest Danish wood pellet user is Dong Energy. Its Avedoere Unit 2 CHP plant uses around 800,000 tons annually, of which 700,000 tons are used during the seven-month long winter season. Dong is now installing a fourth hammermill to expand the pellet-burning capacity in Unit 2 by 80 to 100 percent. A new biomass crane was installed in the plant’s port facility last summer, speeding up pellet unloading to 800 tons per hour. This, together with a new conveyor belt, will make it possible to increase pellet use during the next winter season to almost 900,000 tons. A long-term heat supply agreement with the local district heating companies is running until 2027. For the time being, Avedoere Unit 1 will continue burning coal.

The second big user of pellets in Copenhagen is the Amager plant, sold last year by the Swedish utility Vattenfall to Hofor (formerly Copenhagen Energy). Unit 1 of this plant reopened after retrofitting in 2009, using around 380,000 tons of wood and straw pellets annually. The Amager power station includes two CHP units with a combined electric generation capacity of 314 MW and a combined heat capacity of 583 MW. This spring, Hofor announced plans to replace coal with wood chips at the second Amager unit in 2020.

Pellets to the Avedoere and Amager plants are supplied by bulk ships and barges to the plants’ port facilities. Amager’s east harbor port has 10 berths. Denmark’s two big power producers initially built pellet facilities in Koege. Dong closed its 160,000 ton-per-year plant in 2007 in favor of buying pellets on the market. Vattenfall sold its 110,000 ton-per-year plant to Blue Point Pellets A/S last year, which has said it will continue production at the mill.

The third contributor to the heat and power for the Copenhagen metropolitan area is under construction—a spectacular waste-fed CHP plant. The futuristic Amager Bakke facility will burn waste materials for heat and power, while providing new recreational features—a year-round open ski slope built on the roof of the plant and a climbing wall.

Pellet Suppliers

Denmark relies upon imported biomass to fuel its power and heat systems. Domestic production of wood pellets constitutes only about 100,000 tons, or 5 percent of total supply, with little indication of greater domestic production in the future. The lack of supply and expensive raw materials are the biggest limiting factors. The main countries currently supplying Denmark include Latvia, Estonia, Lithuania and Russia. Import statistics are unclear, however, and information is often mixed and thus to be treated with care.

A number of companies are competing for the mid- and small-scale markets. Swedish Ekman Group is a leading supplier, having overtaken Vapo A/S and Statoil’s distribution nets in Denmark. In October, Ekman received 39,500 tons of pellets from the U.S. on the bulk carrier Orient Tiger and early this year, another 57,500 tons arrived on a ship from the United States. The Fredericia Bulk Terminal handles Panamax ships and with five cranes, can unload 30,000 tons in 72 hours. They are also equipped with a screening unit and bagging service. Other companies actively supplying pellets to Denmark are German Pellets, Graanul Invest, Neova and Verdo/Flexheat and Copenhagen Merchants.

Advertisement

Advertisement

Future Projects

Dong Energy has two biomass conversion projects in development in Denmark, one at Skaerbaek Heat and Power Station in Kolding and one at Studstrup Heat and Power station in Aarhus. Negotiations regarding heat contracts are ongoing and final decisions have yet to be made. “We expect that Studstrup will start in the autumn 2016 and Skaerbaeck in 2017,” reports Carsten Birkeland Kjaer, communication manager at Dong Energy.

The 389 MW Unit 3 in Studstrup is using coal today with a blend of up to 15 percent straw, running until 2015 under a prolonged offset heat agreement with Affald Varme Aarhus. The plant will be converted to 100 percent pellets with a yearly expected consumption of 525,000 to 600,000 tons. Studstrup has its own port facilities with a depth of 11.2 meters.

In Skaerbaek, a new wood chip-fed CHP unit will be built to replace the existing gas CHP plant. But first, a new agreement must be signed with a local energy distributing company. Additional investments will be required for a harbor upgrade, storage buildings, a new boiler and integration with the existing units. A decision for the investment is expected in June.

In Odense, Denmark’s third-largest city, Vattenfall operates the coal-based CHP plant, Fynsverket. Unit 8, with an electric capacity of 35 MW and heating at 110 MW, is replacing 100,000 tons of coal per year with straw. But, the main Unit 7 still uses 650,000 tons of coal annually. Vattenfall has said it does not currently find further biomass conversions to be economical, but that will be re-evaluated in 2018.

The CHP plants in Aalborg and Esbjerg owned by Vattenfall and Dong, respectively, have not been tapped for conversion to biomass.

Not far away from Fynsverket, in Aabenraa close to the German border, Vattenfall acquired Dong’s remaining share in April to become the sole owner of the Ensted transit coal port. With a water depth of 18 meters, the port can receive the largest ocean freighters. Dong has activated a transit port located in Stigsnaes, where ocean freighters with coal or pellets can be transloaded to barges for further transport.

Wood pellets are also used in smaller plants in cities such as Herning (70,000 tons per year), Lemvig and Skive. Since 2009 in Skive, pellets fuel a fluidized-bed gasifier to be converted to electricity and heat in three gas engines, producing 11 MW thermal heat and 3.2 MW electrical power. In the city of Randers, Verdo Energi has a CHP plant, importing wood chips produced from old rubber trees in West Africa via the Aarhus port. The company also runs two pellet production mills in the UK.

Biomass CHP isn’t the only renewable energy development gaining steam in Denmark. The Maabjerg energy concept is integrating big-scale biogas with CHP and second-generation cellulosic ethanol. So far, the biogas and CHP units have been built and negotiations are underway for financing the ethanol plant. Dong Energy is part owner of Inbicon, which has a biorefinery at Kalundborg demonstrating its cellulosic ethanol process. In addition, Dong announced in February a new collaboration with Finnish Neste Oil to produce renewable diesel and aviation fuel from agricultural residues.

Author: Lennart Ljungblom

Bioenergy Writer, Stockholm, Sweden

lennart.ljungblom@mac.com

+ 46 - 70 739 01 05

Upcoming Events