Syngenta grows Enogen corn footprint

Syngenta

January 9, 2017

BY Syngenta

Syngenta recently announced that it has reached agreements with ethanol plants, from Arizona to Ohio, with a combined total capacity of nearly 2 billion gallons.

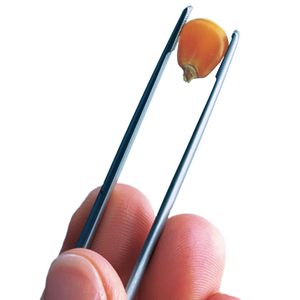

According to Miloud Araba, head of Enogen technical services at Syngenta, the robust alpha amylase enzyme found in Enogen corn hybrids helps an ethanol plant dramatically reduce the viscosity of its corn mash and eliminate the need to add a liquid form of the enzyme.

“This breakthrough viscosity reduction can lead to unprecedented levels of solids loading, enabling increased throughput and yield, as well as significant cost savings from reduced energy, water, natural gas and chemical usage in ethanol plants,” Araba said.

Golden Harvest and NK Corn growers who plant Enogen corn benefit as well—they can earn up to 40 cents per bushel when contracted Enogen grain is delivered to the ethanol plant.

“This is particularly significant given current commodity prices,” said Marcos Castro, Enogen marketing manager at Syngenta. “We expect the total premiums earned by Enogen growers to be approximately $32 million in 2017, creating real advantages for growers and rural economies.”

Advertisement

Improved ROI potential on ethanol acres

Approximately 40 percent of the U.S. corn crop is used to produce ethanol. Syngenta offers the Ethanol Grower Advantage program to help increase potential for a better return on investment on ethanol acres, help increase grower profitability and help plants produce more ethanol per bushel.

“The Ethanol Grower Advantage program incentivizes and rewards agronomic best practices, helping growers to achieve consistently higher yields and earn premiums while delivering higher-quality, locally sourced grain to participating ethanol plants,” Castro added. “Participating growers are eligible to receive up to a 10-cent premium for each bushel of Golden Harvest, NK and/or Enogen corn delivered to a participating ethanol plant. This complements the existing premiums that can be earned by Enogen growers and further demonstrates our commitment to ethanol.”

Growers as enzyme suppliers

Enogen is rapidly gaining popularity because of the value it delivers and the opportunity it provides corn growers to be enzyme suppliers for their participating local ethanol plants. Numerous trials have shown that Enogen hybrids perform equal to or better than other high-performing corn hybrids.

“The agreements we have in place with a steadily increasing number of plants will enable them to source alpha amylase directly from growers and keep enzyme dollars in those local communities,” said Ron Wulfkuhle, head of Enogen at Syngenta. “This is what truly sets Enogen corn apart from other technologies designed to enhance ethanol production. It adds significant incremental value at the local level for communities that rely on their ethanol plant’s success.”

Advertisement

The future of fuel

Looking ahead, Wulfkuhle added that the combination of Cellerate process technology and Enogen corn will help ethanol plants increase efficiency even further. Cellerate converts corn kernel fiber into cellulosic ethanol and can help plants produce more ethanol from the same kernel of corn, increase total yield of distillers corn oil and improve the protein content of feed co-products. Trials at Quad County Corn Processors demonstrated as much as a 26 percent increase in in production when Cellerate process technology and the use of Enogen corn were combined.

“We believe that not only will Cellerate process technology help make advanced and cellulosic ethanol a reality, but the combination of Cellerate and Enogen could represent the next step forward for ethanol production,” Wulfkuhle said.

Related Stories

A planned sustainable aviation fuels (SAF) production facility being developed by SkyNRG Americas in Walla Walla, Washington, has been awarded a new $1.5 million grant from the Washington State Department of Commerce.

Neste MY Renewable Diesel has helped fuel Rio Tinto’s Pilbara iron ore operations for the first time, with the completion of a successful trial of biofuel across its network of Western Australian ports, railways and mines.

The Singapore Airlines Group has signed a memorandum of understanding (MoU) to potentially source neat SAF from Aether Fuels, a climate technology firm that plans to set up SAF production plants in the U.S. and South East Asia.

XCF Global Capital Inc. on Feb. 24 announced that New Rise Renewables LLC has commenced production of neat SAF. The company has also entered into an irrevocable corporate purchase order for the sale of more than 3 million gallons of SAF.

Air Products on Feb. 24 announced its has terminated its agreement with World Energy for the sustainable aviation fuel (SAF) expansion project in Paramount, California. According to World Energy, current operations at the Paramount facility are not affected.

Upcoming Events