Innovative catalysts open new opportunities in biodiesel market

July 16, 2014

BY William Summers

The current, widely used process for producing biodiesel dates to chemistries extant since the late 19th and early 20th centuries: batch operations, using homogeneous catalysts, batch separations, and the like. As the U.S. biodiesel industry began to expand rapidly in 2005, U.S. producers faced the persistent problems of competing with the food industry for the same feedstock—refined, bleached, and deodorized (RBD) soybean oil—and ever-increasing prices and thinner margins. Along with this came the still-simmering “food vs. fuel” debate over how US agricultural potential should be allocated.

While the opportunity for a new biodiesel technology capable of processing nonfood feedstock was vast, to be commercially viable such a technology had to be better suited to large-volume commodity production, to be largely insensitive to feedstock variability, and to provide a better return on invested capital than existing technologies. For Benefuel (Irving, Texas), the challenge was to surpass the initial entry of Axens (Salindres, France) Esterfip-H catalyst, which entered the US market in 2007.

In working with our partners at the National Chemical Laboratory (NCL; Pune, India), a new solid powder catalyst capable of both esterification and transesterification emerged.

This new catalyst afforded high yields of fatty acid methyl esters (FAME) and glycerin under mild conditions (Sreeprasanth et al., 2006) using a wide variety of available fats and oils.

Free fatty acids (FFA), which are common in less refined and less expensive feedstocks such as poultry fat, yellow grease, and palm oil derivatives, have long posed serious problems in conventional biodiesel processing. Benefuel licensed the exclusive worldwide rights to this NCL technology in 2006 and continued discovery and development work with NCL.

Within the first year after signing the license agreement, Benefuel had developed with NCL a second solid catalyst—more suited to fixed-bed applications and thus large-scale commercial fuel production—to accompany the first powder catalyst, which is highly effective in batch operation. Both catalysts are effective in converting fatty acids (FA), fats or oils, and mixtures of these into methyl esters. Benefuel began work on process scale-up in fixed-bed reactors in 2008.

To us, the path ahead was clear: The biodiesel industry needed a fully continuous, fully integrated production refinery for biodiesel—one that could receive a variety of feedstocks and process them continuously to biodiesel and glycerin. The fixed-bed reactor design and our new catalyst were at the heart of this approach.

Although the wide versatility of our catalysts for esterification and transesterification were well recognized, development of other applications had to wait for process validation in biodiesel.

Benefuel’s Ensel fixed-bed process is quite simple. It employs our second solid catalyst, which was developed in conjunction with Süd-Chemie India Pvt. Ltd. (Kerala) and patented in the U.S. and Japan (US 8,124,801 and JP 5,470,382) with applications in other countries.

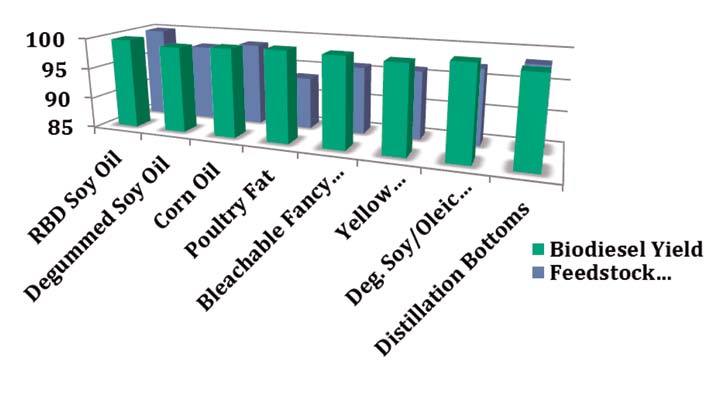

This durable, promoted, metal oxide catalyst is largely insensitive to water and effectively converts every feedstock that has been tested in numerous pilot plant-scale operations.

Advertisement

Advertisement

Examples include degummed soybean oil, cottonseed oil, corn oil from dried distillers’ grains with solubles, yellow grease, beef tallow, crude palm oil, palm fatty acid distillate, and even a mixture of degummed soybean oil and oleic acid (7:3, vol/ vol).

The basic design of Benefuel’s Ensel process for transesterification involves three major components: fixed-bed reactors, an oil–glycerin separation stage, and a pair of distillation columns. Each element of the process operates continuously and can be monitored at critical points with inline sensors for tight control.

The process starts with renewable, inedible feedstock, requiring some minimal pretreatment to remove insolubles and water, which would otherwise displace feedstock. The catalyst is contacted with methanol and feedstock under specific conditions of temperature (190 to 210 degrees Celsius), pressure (40 to 50 bar) , and flow rate (weight hourly space velocity = 0.4–0.6/ hr), followed by recovery and refinement of the excess methanol, product separation, and FAME distillation. Still bottoms can be recycled to increase carbon efficiency, and the glycerin co-product is low in both ash and nonglycerol organic matter.

The reactor is generally columnar in shape, suited for medium-pressure service at moderate temperatures in flooded mode. In this vessel, the reagents—triglycerides (TG) and an excess of methanol in the liquid phase—come in contact with the active catalyst’s surface, which accelerates the transformation of the glycerides to methyl esters.

As the liquid stream exits the reactor, the pressure is reduced on the stream of crude biodiesel, and methanol and the volatile methanol (and water if the feedstock contains FFA) quickly flash to vapor and are carried directly to the methanol refining distillation unit.

The separation can be a simple decanter, in which the product crude biodiesel (the oil layer) and glycerin mixture separates because of the difference in density. Benefuel also holds exclusive rights in a novel electrostatically enhanced separation system, which can dramatically shorten the residence time compared to conventional decanters.

The recovered glycerin can be pumped to a small vacuum distillation column to remove any volatiles (3 to 4 percent of total glycerin volume) and then to coproduct storage. The volatiles, consisting mostly of water and methanol, are pumped to the methanol recovery system.

Distillation of the recovered oil phase is the last stage of the process. This two-step distillation removes any residual volatiles (first stage: residual methanol, water, and volatile unsaponifiables) and refines the methyl esters from any higherboiling impurities (second stage: unconverted glycerides and high-boiling unsaponifiables). The recovered methyl esters are continuously analyzed against ASTM specifications for B100 validation.

Distillation of the crude biodiesel ensures continuous, high-quality output and minimal risk of cold flow issues caused by residual glycerides. As specifications continue to tighten, even conventionally designed biodiesel plants are adding a final stage distillation.

In 2009, as work on the biodiesel process scale-up shifted from NCL’s labs to Benefuel’s domestic and Japanese pilot plants, work at NCL refocused to develop other reaction modes with these same catalysts. Among these are the conversion of TG or fatty acids into alkyl fatty acid esters with higher-boiling alcohols and of FAME and acyl glycerides into polyol esters, for which we now have three separate process modes: batch (stirred tank reactor) and continuous (fixed bed reactor or catalytic reactive distillation).

These processes leading to biodegradable lubricant base oil and other oleochemicals await pilot-scale testing for commercial applications.

Advertisement

Advertisement

The solid catalyst advantage

The advantages of solid catalytic processing are simply economic—continuous production at commercial scale without reference to periodic changes of feedstock or feedstock blends; a catalyst life of several years instead of “catalyst as reagent,” as in conventional biodiesel production; and an ability to blend feedstocks to achieve optimal cold-flow properties in the final product at a low raw material cost.

When compared on the basis of production, Benefuel estimates that the Ensel process has the lowest cost producer advantage in the market. This competitive advantage offers ENSEL producers a strong economic edge over conventional biodiesel production processes in their numerous variations. Except for “green” diesel, which requires a source of hydrogen and affords no glycerin coproduct, Ensel can be adapted to existing and greenfield operations. Benefuel is currently partnered with Flint Hills Resources LLC (Wichita, Kan.) in the retrofitting of the former Axens’ biodiesel plant in Beatrice, Neb., to operate with the Ensel process and is engaged in one other U.S. greenfield biodiesel project, while pursuing other opportunities in Southeast Asia and Canada.

Author: William Summers

Chief Science Officer, Benefuel Inc.

wsummers@benefuel.net

This article originally appeared in the July/August 2014 issue of Inform magazine. It has been reprinted in Biodiesel Magazine with permission from AOCS (www.aocs.org).

Works cited

-Sreeprasanth, P.S., R. Srivastava, D. Srinivas, and P. Ratnasamy, Hydrophobic, solid acid catalysts for production of biofuels and lubricants, Appl. Catal. A: General 314:148–159, 2006.

-Srinivas, D., P. Rattnassamy, S.A. Pardhy, T. Raja, S.S. Deshpande, et al., Process of manufacturing of fatty acid alkyl esters, US Patent 8124801 and Japanese Patent 5470382, Benefuel Inc., February 28, 2012.

Related Stories

Biodiesel capacity in the U.S. and Canada dipped slightly stable in 2024, with several renewable diesel producers reporting headwinds and lower margins alongside a drove of SAF projects in various stages of development.

The IEA’s Task 39 group has new research regarding the development and status of the sustainable aviation fuel industry.

The U.S. EPA on Nov. 16 released updated RIN data, reporting that nearly 2.11 billion RINs were generated under the RFS in October, up from 1.81 billion generated during the same month of last year.

Conestoga to host SAFFiRE cellulosic ethanol pilot plant

Conestoga Energy and SAFFiRE Renewables LLC announced on Nov. 16 their agreement for Conestoga to host SAFFiRE’s cellulosic ethanol pilot plant at Conestoga’s Arkalon Energy ethanol facility in Liberal, Kansas.

Officials at Calumet Specialty Products Partners L.P. discussed the company’s proposed plans to boost sustainable aviation fuel (SAF) production at its Montana Renewables biorefinery during third quarter earnings call, held Nov. 9.

Upcoming Events