JM Davy earns prestigious award for reactive distillation process

Photo: Johnson Matthey

December 1, 2014

BY Ron Kotrba

The team at Johnson Matthey Davy Technologies was recognized at the prestigious annual Institution of Chemical Engineers (IChemE) Awards last month by winning the IChemE Sustainable Technology Award for its development of a reactive distillation process for biodiesel production. The technology is geared toward converting low-quality feedstocks to market-ready biodiesel efficiently and economically, the company says.

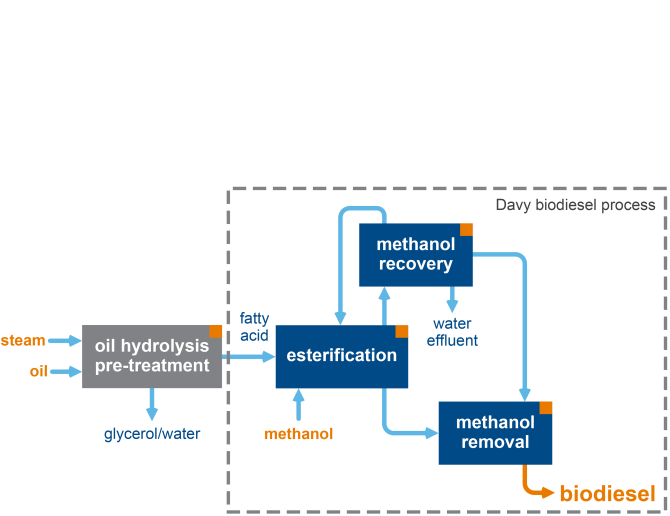

The Johnson Matthey Davy Technologies website explains the process, which begins with conventional oil hydrolysis to produce fatty acids plus a clean water/glycerol stream. “The molten fatty acid then passes to the esterification reaction column,” the website states. “The preheated liquid fatty acids feed to the top of the esterification reaction column, in which they react with methanol vapor to form their equivalent methyl fatty esters. The reaction proceeds in the presence of a proprietary solid catalyst, achieving complete conversion to the methyl ester product. The water produced in the esterification reaction is stripped out of the methyl esters by excess methanol. This methanol/water mixture leaves the reactor as overheads and moves to a methanol column for separation, with the resulting dry methanol recycling back to the esterification reaction column. The crude liquid methyl esters exit from the bottom of the column then proceed to purification. A two-stage flash system removes any small amounts of methanol from the crude methyl ester product. Following preheating, the product stream enters flash pot no. 1, which, operating at atmospheric pressure, removes most of the methanol present. Flash pot no. 2, operating under vacuum, removes any final methanol, leaving market-quality biodiesel which is sent to storage. The flashed methanol recycles back into the process.”

Michael Winter, technology manager at Johnson Matthey Davy Technologies, said the technology is a valuable, attractive and sustainable option for its customers, “and being recognized in this way is a great achievement for everyone involved.”

Advertisement

Advertisement

Advertisement

Advertisement

Related Stories

Biodiesel capacity in the U.S. and Canada dipped slightly stable in 2024, with several renewable diesel producers reporting headwinds and lower margins alongside a drove of SAF projects in various stages of development.

The IEA’s Task 39 group has new research regarding the development and status of the sustainable aviation fuel industry.

The U.S. EPA on Nov. 16 released updated RIN data, reporting that nearly 2.11 billion RINs were generated under the RFS in October, up from 1.81 billion generated during the same month of last year.

Conestoga to host SAFFiRE cellulosic ethanol pilot plant

Conestoga Energy and SAFFiRE Renewables LLC announced on Nov. 16 their agreement for Conestoga to host SAFFiRE’s cellulosic ethanol pilot plant at Conestoga’s Arkalon Energy ethanol facility in Liberal, Kansas.

Officials at Calumet Specialty Products Partners L.P. discussed the company’s proposed plans to boost sustainable aviation fuel (SAF) production at its Montana Renewables biorefinery during third quarter earnings call, held Nov. 9.

Upcoming Events