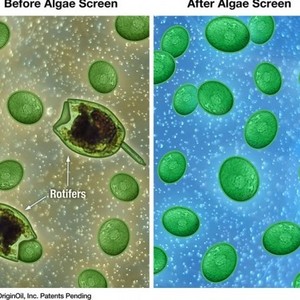

Algae Screen demonstrates 'dramatic drop in contaminant load'

Image: OriginOil

November 25, 2013

BY OriginOil Inc.

OriginOil Inc., developer of Electro Water Separation, the high-speed, chemical-free process to clean up large quantities of water, announced that academic testing has verified its new Algae Screen growth optimizer effectively controls bacteria and microscopic predators in commercial algae production, helping to promote high rates of cultivation of the most valuable species.

“Initial test results saw a dramatic drop in contaminant load while the culture still maintained target cell integrity,” said Matt L. Julius of the Department of Biological Sciences at St. Cloud State University in Minnesota. “This is one technology that will change the industry once it is fully validated.”

Advertisement

The researcher, who intends to publish a peer-reviewed paper on the process, found that the Algae Screen prototype required less than 0.1 watt-hour of electricity per gallon of treated water. This means an Algae Screen Model 60, offering a 60-liter-per-minute capacity, can treat a 40,000-liter pond or bioreactor for less than 10 cents per day, pumping extra.

Microbiological control is one of the major barriers to commercial-scale algae production today. Bacteria, rotifers and ciliates can easily take hold of a culture and induce the “crash” of a commercial algae production system. This is especially true of algae used in high-end commercial products, such as Hematococcus pluvialis, which produces one of the most valuable algae products, Astaxanthin, priced at about $4,000 a kilogram. Other species are even more at risk of bacterial and predator contamination, for instance, Botryococcus braunii.

“B. braunii has tremendous potential in fuels and nutrition due to its very high oil content,” said Thomas Ulrich, previously a group leader and principal scientist at the U.S. DOE’s Idaho National Laboratory and now an OriginOil advisor. “But that same fattiness makes it a prime target for predators, preventing its use in large-scale open ponds. If these promising research numbers continue to hold true, Algae Screen could actually make industrial production of high-oil algae possible, which in turn could make competitive ‘green’ fuel a reality. Cheap, clean fuel could be a real game-changer.”

Advertisement

Algae Screen specifications and product information are available at its product page. The Model 60 is available now. The price of $5,900 plus shipping includes remote consultation with Jose Sanchez Piña, OriginOil’s vice president of quality assurance and services, to adapt the system to the customer’s strain, processing flow and growth conditions. Discounts are available for volume purchases.

The Algae Screen will be offered in multiple sizes from 4 liters per minute for modular and research operations to the multi-thousand-liter scale required for commercial operations.

OriginOil first filed for patent protection on the Algae Screen on March 18, 2011, in a U.S. Patent Office Application entitled “Enhancing Algae Growth By Reducing Competing Microorganisms In A Growth Medium,” describing a method “by which a growth medium is exposed to an electric field of sufficient magnitude to kill competing microorganisms and insufficient magnitude to cause flocculation to an algae population.” The company filed for Patent Cooperation Treaty protection on March 13, 2012.

Related Stories

SAF Magazine and the Commercial Aviation Alternative Fuels Initiative announced the preliminary agenda for the North American SAF Conference and Expo, being held Sept. 22-24 at the Minneapolis Convention Center in Minneapolis, Minnesota.

Scientists at ORNL have developed a first-ever method of detecting ribonucleic acid, or RNA, inside plant cells using a technique that results in a visible fluorescent signal. The technology could help develop hardier bioenergy and food crops.

The 2025 International Fuel Ethanol Workshop & Expo, held in Omaha, Nebraska, concluded with record-breaking participation and industry engagement, reinforcing its role as the largest and most influential gathering in the global ethanol sector.

TotalEnergies and Quatra, the European market leader in the collection and recycling of used cooking oil, have signed a 15-year agreement beginning in 2026, for the supply of 60,000 tons a year of European used cooking oil.

The USDA maintained its forecast for 2025-’26 soybean oil use in biofuel production in its latest World Agricultural Supply and Demand Estimates report, released June 12. The estimate for 2024-’25 soybean use in biofuel production was revised down.

Upcoming Events