BPTS addresses biodiesel history, technology advancements

September 24, 2020

BY Erin Krueger

BBI International’s Biodiesel Production Technology Summit kicked off on Sept. 16 with the star-studded story of Pacific Biodiesel Technologies unique history and a general session panel focused on emerging biodiesel technologies.

Bob King, founder and president of Pacific Biodiesel, opened the event with a keynote address that provided an inside view of his company’s unique 25-year history as a founding member of the U.S. biodiesel industry.

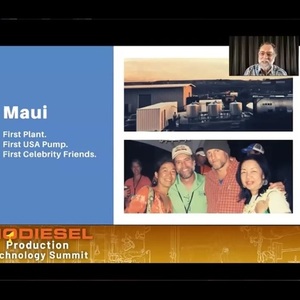

Pacific Biodiesel opened its first facility in Maui back in 1995. That community-scale facility had an annual production capacity of approximately 250,000 gallons per year and provided fuel for local use. Actor Woody Harrelson was among the plant’s early customers.

The company was soon approached to develop a plant in Japan for the 1998 Winter Olympics. King said that facility was developed quickly and began operations before the Olympic games begun. It took in used cooking oil from the area, including KFC restaurants. A portion of the resulting fuel was used to generate heat and power for one restaurant.

Soon Pacific Biodiesel was approached by Willie Nelson and his wife, Annie, early supporters of biodiesel, who asked the Kings to build a biodiesel plant in Texas next to a truck stop. That plant made fuel out of locally sourced cottonseed oil and used cooking oil.

A construction boom soon followed during which the company built half a dozen plants all over the country. Those plants were all community scale plants of 500,000 gallons up to 5 MMgy, King said.

Advertisement

Additional celebrity supporters, including Jack Johnson and Daryl Hannah, started to help tell the biodiesel story. Hannah was among those that helped launch the Sustainable Biodiesel Alliance alon gwith Kelly King and Annie Nelson as a result of growing concerns over sustainability practices.

King noted the first ASTM specification for biodiesel was launched in 2002 and underwent several changes. Around 2008, Pacific Biodiesel decided to expand its facility in Salem, Oregon, to approximately 5 MMgy and upgrade its technology to include more automation and a dry wash process.

The technology of diesel engines continued to change, King said, and the industry had to keep improving the ways in which it was making fuel. This included the adoption of distillation technologies, methanol recycling, and even the addition of a generator facility that allowed its Big Island refinery to use renewables to generate 100 percent of its required heat and electricity. Soon, the company began to focus on ways to use more degraded feedstocks.

Now, 25 years after the company first began operations, Pacific Biodiesel has grown to almost 100 employees. King said the COVID-19 pandemic has again revealed the benefits of community-based fuel projects. Not only do community-based projects provide jobs, they also provide locally produced fuels while traditional worldwide supply chains can prove problematic in times of crisis.

King said his experience in the biodiesel industry has been worth it. “It’s been a wild ride—ups and downs,” he said, noting there were several times he thought his company would go out of business. “We figured a way forward,” he said “It felt good and it continues to drive us,” he added and thanked all the people who have helped build the biodiesel industry. Pacific Biodiesel is looking forward to another 25 years, he said.

King’s keynote was followed by a panel discussion focused on new biodiesel technologies.

Advertisement

Tom Slunecka, CEO at Ag Management Solutions, discussed a new technology being launched by Plasma Blue. He called the technology a revolutionary new way of making biodiesel that uses the transesterification process, but brings in new elements that have not before been used.

While traditional biodiesel production processes require catalyst, heat, mixing and time, he said Plasma Blue’s technology produces fuel without traditional heat or mixing. “We use electricity to excite the molecules into a state of plasma,” he said, noting the process uses the same type of catalyst and same type of oil and methanol relationship as traditional biodiesel production. The process creates plasma in a millisecond, he said, and in a continuous flow.

One advantage of the Plasma Blue process is that it uses electricity to drive the process, not natural gas. As a result, some plants can fully convert to renewable energy using solar and wind. The technology also allows ethanol to be used in the place of methanol. The technology holds particular promise for co-location at ethanol plants, Slunecka said, allowing those facilities to use corn oil and ethanol already onsite to produce a new fuel. The footprint of the required equipment is also small, he added, noting that a 1.5 MMgy unit is roughly the size of a golf cart.

Armin Brandner of Europe-based Air Liquide discussed a supercritical biodiesel technology his company is offering in partnership with Inventure. He said the technology accepts any feedstock without pretreatment, is scalable, needs no catalyst and generates a higher quality of glycerin. The technology also allows producers to switch between feedstock with no buffer.

Rudy Pruszko of Pruszko Consulting provided attendees with an overview of considerations they should make when evaluating any new technology for possible addition to their plants. He said with any technology there is always a trade-off between benefits and drawbacks. It’s important to understand what those trade offs are, he said.

Important considerations when evaluating new technologies include allowable feedstocks and required infrastructure. Pruszko encouraged attendees to review test data, talk to others who are already using the technology, consider the cost of the technology in terms of royalty payments or licensing fees. He also said its important to ask about a technology supplier’s ROI calculations, do your own ROI calculations specific to your plant operations, and ensure that any performance guarantees are tied to your actual feedstock.

Related Stories

Marathon Petroleum Corp. on Aug. 5 released second quarter financial results, reporting improved EBITDA for its renewable diesel segment. The company primarily attributed the improvement to increased utilization and higher margins.

Chevron Corp. on Aug. 1 confirmed the company started production at the Geismar renewable diesel plant in Louisiana during the second quarter after completing work to expand plant capacity from 7,000 to 22,000 barrels per day.

The public comment period on the U.S. EPA’s proposed rule to set 2027 and 2027 RFS RVOs and revise RFS regulations closed Aug. 8. Biofuel groups have largely expressed support for the proposal but also outlined several ways to improve the rulemaking.

In celebration of World Biodiesel Day, MOL Group on Aug. 8 announced SAF was successfully produced for the first time at INA’s Rijeka Refinery during a pilot project to process biocomponent. Renewable diesel was also produced.

Iowa farmers have a new market opportunity for their 2025 soybean crop. Landus is expanding its Clean Fuel Regulation initiative, made possible by recent policy changes expected to increase Canada's demand for liquid biofuel.

Upcoming Events