Cellerate process technology earns EPA certification for D3 RINs

Syngenta

October 20, 2014

BY Syngenta

Quad County Corn Processors has achieved U.S. EPA certification to generate D3 renewable identification numbers (RINs) for cellulosic ethanol produced with Cellerate process technology. Formerly known as Adding Cellulosic Ethanol, Cellerate is a collaboration between Syngenta and Cellulosic Ethanol Technologies LLC, a wholly owned subsidiary of Quad County Corn Processors.

QCCP earned D3 pathway approval from the EPA on Oct. 7 and Quality Assurance Program certification on Oct. 10. Clearing these hurdles led to production of QCCP’s first QAP D3 RINs on Oct. 16.

To qualify as cellulosic biofuel, a renewable fuel must meet a 60 percent threshold for lifecycle greenhouse gas emissions. RINs are used for compliance with the renewable fuel standard (RFS) program and may be "banked," traded or sold for use by parties (fuel producers and importers) who must comply with the RFS.

According to QCCP Chief Executive Officer Delayne Johnson, as cellulosic D3 RINs become available on the commercial market, biofuels opponents will no longer be able say there are no D3 RINs as a strategy to weaken the RFS.

“The biofuels industry now has the technology available to create 2 billion gallons of cellulosic ethanol – with no more corn,” Johnson said. “QCCP is proud to be one of the first companies to issue D3 RINs. We look forward to higher D3 RIN requirements in 2015 as new production comes on.”

In July 2014, collaboration between Syngenta and Cellulosic Ethanol Technologies produced the first commercial-scale cellulosic ethanol in Iowa. QCCP expects to produce 1 million gallons of cellulosic ethanol in 2014 and 2 million gallons in 2015. Earlier this year, Syngenta announced an agreement with Cellulosic Ethanol Technologies to license Cellerate process technology to ethanol plants.

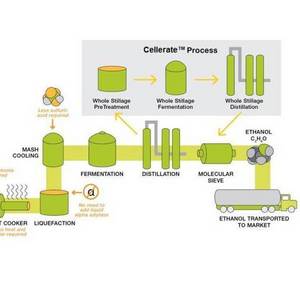

“Cellerate is designed to increase an ethanol plant’s production by allowing the corn kernel fiber to be converted into cellulosic ethanol,” said Jack Bernens, head of marketing and stakeholder relations for Enogen corn enzyme technology. “Ethanol plants can easily integrate Cellerate process technology into their existing production process. Cellerate, in conjunction with Enogen corn, will deliver notable benefits to ethanol plants beyond what can be achieved through either technology alone.”

Advertisement

Advertisement

Related Stories

The U.S. EPA on July 8 hosted virtual public hearing to gather input on the agency’s recently released proposed rule to set 2026 and 2027 RFS RVOs. Members of the biofuel industry were among those to offer testimony during the event.

The USDA’s Risk Management Agency is implementing multiple changes to the Camelina pilot insurance program for the 2026 and succeeding crop years. The changes will expand coverage options and provide greater flexibility for producers.

President Trump on July 4 signed the “One Big Beautiful Bill Act.” The legislation extends and updates the 45Z credit and revives a tax credit benefiting small biodiesel producers but repeals several other bioenergy-related tax incentives.

CARB on June 27 announced amendments to the state’s LCFS regulations will take effect beginning on July 1. The amended regulations were approved by the agency in November 2024, but implementation was delayed due to regulatory clarity issues.

SAF Magazine and the Commercial Aviation Alternative Fuels Initiative announced the preliminary agenda for the North American SAF Conference and Expo, being held Sept. 22-24 at the Minneapolis Convention Center in Minneapolis, Minnesota.

Upcoming Events