CFIs Help Make Biodiesel Fit for Purpose, Price-competitive

PHOTO: EVONIK OIL ADDITIVES USA INC.

August 10, 2017

BY Alex Tsay

Global energy consumption has been growing the past 30 years, except in 2008, due to the economic crisis. Many forecasts call for the increase in demand to continue—and not only for crude oil, but also for gas and coal. With growing concerns about the global warming associated with greenhouse gas (GHG) emissions, however, biofuels are becoming a more significant portion of total global energy consumption.

Futurists also see continued increases in global commerce, the car population, and “dieselization” of vehicle fleets. If they are right, strong growth in demand for diesel fuel will contribute to higher diesel prices and supply issues. The result: A growing portion of the increased demand for diesel will be supplied by renewable fuels such as “acceptable” biodiesel. While the definition of “acceptable” is still evolving, note that the current standards for biodiesel require that the fuel be “fit for purpose” and cost-competitive with petroleum diesel. Additionally, its production and consumption must not compete for, or increase, the cost of the food supply, or cause a net increase in GHG emissions.

Feedstocks, Low-temperature Performance

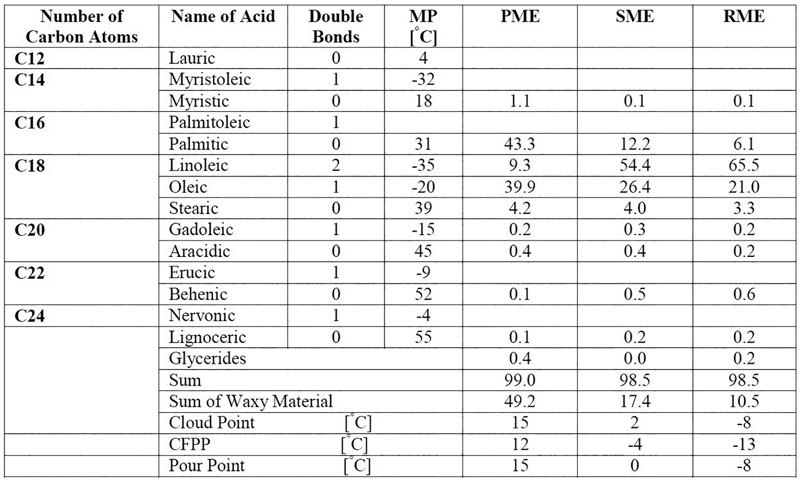

Biodiesel can be a mixture of fatty acid methyl esters (FAMEs) produced from various feedstocks, such as vegetable oil or animal fats. Such a mixture can contain a variety of structures, including both unsaturated and saturated acids, with carbon numbers typically varying between 10 and 24.

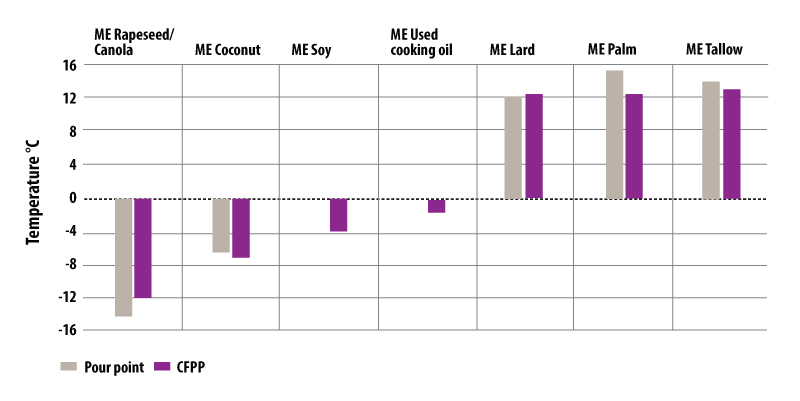

As shown in Figures 1 and 2, the saturated FAME components have such a high cloud point (CP), cold filter plugging point (CFPP), and pour point (PP) that they cannot be used when ambient temperatures are below the respective CPs.

The primary negative influence on biodiesel cold flow properties comes from the crystallization of long-chain, saturated FAMEs at ambient temperature. Failure to address this issue results in the inability to fully utilize these alternative fuels. Consequently, there is a vital need to improve these properties with specific additives to meet the performance standards of current fuel specifications.

FAMEs start as a clear, solids-free liquid at room temperature, such as 20 degrees Celsius. Upon cooling, waxy components begin to crystallize. The temperature at which crystals grow large enough to be seen is defined as the CP and is measured using ASTM D2500 method. Upon further cooling, the waxy crystals continue to grow, eventually becoming large and numerous enough to slow or stop the flow of the FAMEs through a typical vehicle fuel filter. This temperature is determined by the CFPP test, ASTM D6371. As the FAMEs’ temperature continues to decrease, crystals continue to grow in size, forming a network extending throughout the fluid that prevents it from flowing. The temperature at which the fluid ceases to flow is the PP, measured with the ASTM D97 method.

The CP, CFPP and PP are major factors in defining the practical utility of a specific biodiesel, and thus have a significant impact on its value. CP is an early warning sign that waxy material is coming out of solution and might impair flow. CFPP is related to the plugging of the fuel filter by wax crystals whose size matches or exceeds the filter pore size. Filter plugging leads to engine shutdown and immobilized equipment, resulting in loss of time and money. PP is important for FAME producers or transporters who want to avoid frozen biodiesel plugging tanks and lines. Given these operational considerations, FAMEs with better low-temperature performance tend to command a higher value.

PAMA CFIs’ Mechanism of Action

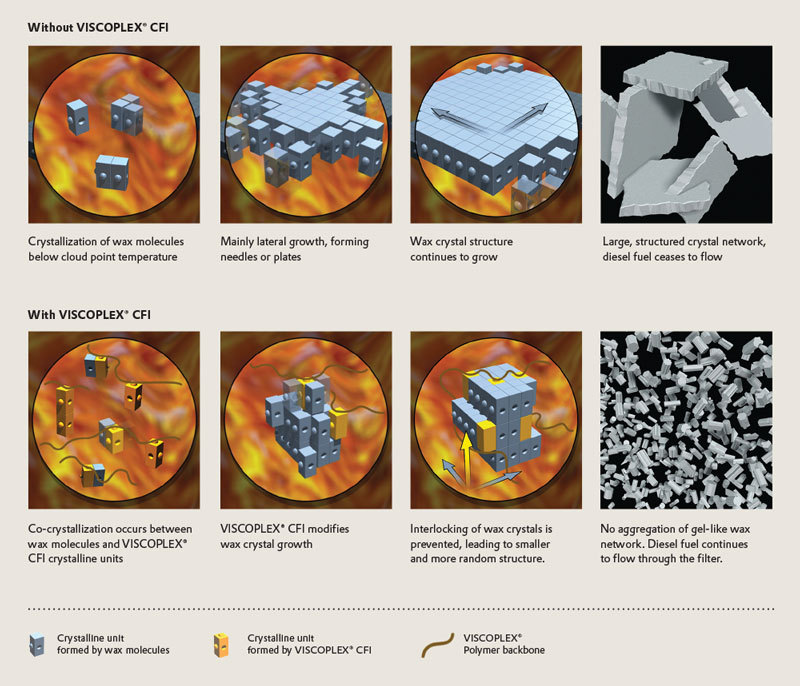

Polyalkylmethacrylates (PAMA) are a widely accepted chemical technology used to make CFI additives. PAMA CFIs can improve the low-temperature properties of FAMEs by controlling the waxy structures formed at low temperatures. This is made possible by their ability to co-crystallize with the biodiesel’s saturated methyl esters crystalizing out of solution as it cools down. See the diagrammatic representation in Figure 3. In the top left drawing, a wax-like crystal has formed with a characteristic needle-like shape. As temperature decreases, the needles grow in size and number, forming a network that impairs the flow of the FAME (Figure 3, top right). PAMA additive alters the rate of crystallization of the waxy components, preventing the formation of large crystals and of a network structure to lower temperatures. The effectiveness of the PAMA depends on the scientists tailoring the distribution of its waxy hydrocarbon side chains that range from 10 to 20 carbon atoms in length along the polymer backbone. When a biodiesel sample containing an appropriate PAMA is cooled, the waxy side chains of the PAMA co-crystallize with the waxy components in the biodiesel (Figure 3, lower drawings). The bulky polymer backbone interferes with the continued growth of the crystals, which are more numerous but also smaller in size.

One area where biodiesel needs improvement in order to be considered fit for purpose lies in its low-temperature properties that are inherently inferior to those of fossil diesel. Biodiesel has a higher CP, CFPP and PP, and it requires specific additive treatment. This has led to the development of new PAMA CFIs engineered to improve the low-temperature performance of a variety of FAMEs to an acceptable level, which greatly increases their market value. Evonik’s Viscoplex CFIs can improve the low-temperature properties of FAMEs by controlling the waxy structures formed at low temperatures. This is made possible by their ability to co-crystallize with the saturated methyl esters in the FAME solution. Since different FAMEs have various waxy components, Evonik has engineered the CFI molecules to improve the low-temperature performance of a variety of FAMEs to substantially increase their market value. See the Viscoplex CFI selection guide (Figure 4).

The oil additives specialists at Evonik are global leaders in the supply of high-performance fuel and lubricant additives for use in automotive, hydraulic and industrial lubricants. State-of-the-art regional technology centers and manufacturing facilities linked through a global supply chain enable Evonik to reliably provide high-quality customized products and solutions to customers worldwide. Evonik’s team of fuel and lubricant specialists is poised to help OEMs, formulators and marketers get an edge and boost efficiency in a range of applications.

Author: Alex Tsay

Global Marketing Manager, Oil and Gas

Evonik Oil Additives USA Inc.

215-706-5808

alex.tsay@evonik.com

Advertisement

Advertisement

Advertisement

Advertisement

Related Stories

Global digital shipbuilder Incat Crowther announced on June 11 the company has been commissioned by Los Angeles operator Catalina Express to design a new low-emission, renewable diesel-powered passenger ferry.

ATR and French SAF aggregator ATOBA Energy on June 19 signed a memorandum of understanding (MOU) to explore ways to facilitate and accelerate sustainable aviation fuel (SAF) adoption for ATR operators.

Argent Fuels, a leading provider of carbon-saving fuels in the UK, is accelerating its efforts to support a greener future. The expansion of its High Blend Biodiesel will supply to bus, coach, HGV fleets and rail in the south of the UK.

Sprague Operating Resources LLC on June 24 announced it has been selected by the New York City Department of Citywide Administrative Services to supply renewable diesel for its marine fleet, including the iconic Staten Island Ferry.

On June 17, the NYC Department of Citywide Administrative Services and the Department of Transportation announced the start of the Staten Island Ferry’s transition to renewable diesel, marked by the delivery of the first barge of fuel.

Upcoming Events