CHS to use Enogen corn at Illinois ethanol plant

Syngenta

January 8, 2018

BY Syngenta

Syngenta has announced an agreement with CHS Inc. to use Enogen corn enzyme technology at its 130-million-gallon ethanol plant in Rochelle, Illinois. CHS is a premier ethanol producer, marketer and trader and one of the nation’s largest suppliers of ethanol-enhanced gasoline.

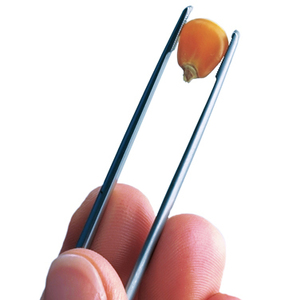

Enogen corn enzyme technology is an in-seed innovation available exclusively from Syngenta and features the first biotech corn output trait designed specifically to enhance ethanol production. Using modern biotechnology to deliver best-in-class alpha amylase enzyme directly in the grain, Enogen corn eliminates the need to add liquid alpha amylase and can help an ethanol plant significantly reduce the viscosity of its corn mash, improving plant performance. And, numerous trials have shown that Enogen hybrids perform equal to or better than other high-performing corn hybrids1.

Advertisement

Advertisement

Enogen corn will provide the CHS Rochelle facility with an industry-leading enzyme for enhanced ethanol production while also supporting local growers and the community. Several million dollars in premiums are expected to be paid annually to growers raising Enogen corn, locally, for the CHS plant in Rochelle.

“CHS is focused on helping its farmer-owners grow,” said Mike Van Houten, CHS Rochelle facility manager. “The Enogen program provides benefits for our plant, but is also a big win for our local community with the premium to be paid on every bushel of Enogen corn brought to us.”

CHS ethanol plants manufacture the alcohol-based renewable fuel via an advanced fermenting and distilling process that efficiently converts corn into simple sugars. The resulting ethanol product is primarily used as a fuel that is commonly blended with gasoline to increase octane and improve emissions quality. The Rochelle plant is an 81-acre, dry mill corn-based operation and was acquired by CHS in June 2014.

Advertisement

Advertisement

“The CHS Rochelle facility is a large, sophisticated ethanol biorefinery,” said Glen Edwards, Enogen account manager for Syngenta. “We are excited to be working with the CHS team in Rochelle to help the facility there operate even more smoothly and efficiently. We are proud to be partnering with CHS help keep enzyme dollars local and invest in the local community. Syngenta is committed to the success of the ethanol industry through helping plants operate more efficiently and growers serve as enzyme suppliers.”

Related Stories

Chevron Lummus Global announced a successful commercial test for coprocessing biogenic feedstocks and fossil feedstocks at INA Group's Rijeka Refinery in Croatia. SAF and renewable diesel were produced during the test.

Phillips 66 on July 25 released Q2 financial results, reporting the company’s Rodeo Renewable Energy Complex in California continues to run at reduced rates due to market conditions. Pre-tax income for the renewables segment was up when compared to Q1.

The EIB and Eni on July 24 signed a €500 million 15-year finance contract to support the conversion of Eni’s Livorno refinery in Tuscany, Italy, into a biorefinery that can produce renewable diesel, renewable naphtha and bio-LPG.

Iowa Secretary of Agriculture Mike Naig announced that the Iowa Renewable Fuels Infrastructure Program Board recently approved an additional 24 applications from Iowa fuel retailers to support new and expanded biofuel infrastructure projects.

CountryMark on July 22 celebrated the completion of more than $100 million in upgrades at its refinery in Indiana, including those related to soybean oil storage. The facility produces renewable diesel via coprocessing technology.

Upcoming Events