Drawing Out More

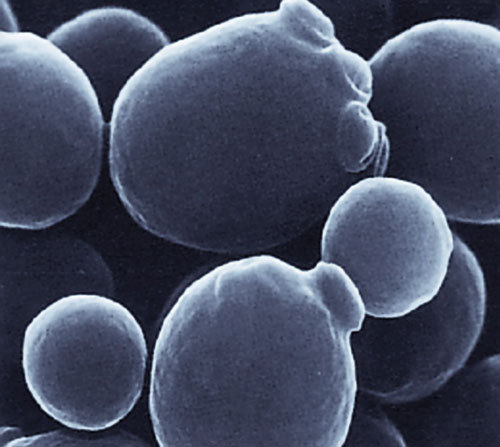

PHOTO: NOVOZYMES

December 14, 2022

BY Luke Geiver

With ethanol producers now wanting yeasts to seemingly do it all—tolerate high heat, drive throughput, offset inputs, reduce costs and lower carbon intensity—it would be understandable if product developers couldn’t meet every ask. But just the opposite seems to be happening. The industry’s top suppliers of bulk yeasts are almost a step ahead of their customers’ requests these days, regularly unveiling new products that improve fermentation times, reduce or eliminate yeast supplement usage and help plants reach new heights of production flexibility and optimization.

In 2022, a team working on developing new and innovative yeasts at Novozymes received results from a customer conversation survey focused on what its producer clients wanted from future products. Brianna Thompson, R&D innovation team leader, and Claudia Geddes, application team leader, along with Kim Bertz, senior manager of product marketing, together explained the survey findings to Ethanol Producer Magazine.

For Geddes, the survey results show an industry that primarily wants four things from yeast products. In no particular order, producers want to make more corn oil; have levers to improve fermentation performance; the ability to convert even more starch and fiber; and strategic opportunities built into their yeast products. Not surprisingly, the research and product development being done by the teams led by Thompson and Geddes has taken significant direction from the survey and other producer input.

“In R&D, we try to take a holistic approach,” Thompson says, explaining how thinking about yeasts in the context of plantwide operational goals helps the company create new lines of “industry-changing” yeast products.

Bertz says Novozymes is always looking at the breadth of its product portfolio. The company wants to provide flexibility to its clients by producing and offering a range of industry-leading products. “We don’t do one-size-fits-all,” she says.

Novozymes’ current portfolio of Innova yeasts includes three main offerings: Apex, Quantum and Turbo. The Innova Apex product allows producers to hit every part of the production curve with confidence, according to Thompson. Apex enables producers to take advantage of market conditions without sacrificing robustness or consistency of bulk production. Apex provides a 2 percent production increase and lower glycerol compared to the company’s previous yeast offerings; and it also ferments up to 36% solids. The strain can tolerate temperature excursions up to 101 degrees Fahrenheit while performing at 0.6 percent lactic acid and 0.4 percent acetic acid present. Innova Apex finishes strong with clean fermentations delivering higher ethanol yields and lower glycerol, all while protecting fermentations with the robustness producers have come to expect from the Innova line. And to help reduce production costs, the product can eliminate yeast nutritional supplements and urea up to 90 percent. Apex is made for fermentation times of 52 to 65 hours.

The Innova Quantum product is designed for longer fermentations, with enhanced robustness and up to 40% lower glycerol. The Quantum product provides yield gains of 2 to 3 percent consistently, tolerates temperatures up to 98 degrees F, can power through lactic acid challenges up to 0.5 percent and also eliminates yeast nutritional supplements and reduces urea up to 90 percent. Quantum is made for fermentation times of 65 hours.

Innova Turbo was created for producers that want to turn up the dial on throughput but, in the past, have had a fear of plant upsets because yeast just weren’t fast enough or capable of tolerating high stress conditions. Turbo pushes up to 36 percent solids for higher ethanol titers, consistently finishes at less than 0.1 percent glucose, tolerates temperatures up to 101 degrees F, performs in 0.6 percent lactic and 0.4 percent acetic acids, and also eliminates nutritional supplements and reduces urea up to 90 percent. Turbo is made for fermentation times less than 52 hours.

All of the products were designed around what Geddes calls “key care-abouts.” One of the main care-abouts has, and will always be, cutting input costs. The ability of all three yeast offerings to reduce yeast supplements and urea is a big part of answering that ask, Geddes says.

Traditionally, producers have added urea to the fermentation process as a nutrient needed to feed yeast so it can produce a resulting ethanol molecule. Although prices for urea were previously low, that has changed. In addition to price, urea can hamper overall fermentation optimization, reduce corn oil yields and negatively impact downstream operations.

The Novozymes team has created a way to deliver ethanol producers a holistic approach to maximize fermentation performance. By combining the power of advanced yeasts with novel liquefaction enzymes available through the Fortiva product family, they create fermentations where Innova yeast products can optimally create more ethanol, and enable higher corn oil yields without additional feedstock.

Liquefaction proteases break down corn protein into small peptides and amino acids, which are easily utilized by the yeast. This means the yeast has more energy to thrive, enabling it to quickly start up and reach peak performance, Geddes explains. Using Fortiva combined with an advanced Innova product can increase corn oil production by a range of 10 to 15 percent, while reducing the need for urea supplements.

Geddes says some ethanol customers have used a urea supplement in the range of 3,000 pounds per fermentation. Reducing those numbers, for example, Geddes says, can save those customers up to $600,000 or more per year, depending on the size of the plant.

While Thompson and her team have worked hard to create a lineup of flexible and innovative yeast products that will, and have, accomplished things not previously seen in the ethanol production industry, Geddes and her team have kept in stride on the application and manufacturing side. After Thompson’s team tests strains in real-world conditions—and some conditions tougher than those found in the real-world—Geddes and other Novozymes personnel make sure the strains can actually be produced and used at the commercial level. Our goal is to ensure each product presents a real value the producer can trust Geddes says.

All of the work maintains a focus on the customer, Geddes and Thompson say. From the latest industry trends (like thermotolerance and clean fermentations) to the desire for flexibility (just as the survey said), the Novozymes team is always looking for ways to debottleneck the fermentation process so its customers can get better results. All of that happens, at least for a top perennial player in the ethanol industry, by creating a robust portfolio filled with products that are taking the industry to new levels of both optimization and production possibility.

Better, Faster, Stronger

The explainer video for Lallemand’s newest yeast product—Fermacore—features a sprinting cheetah, an illustrated arm flexing a bicep, dollar symbols and a handful of other illustrated images. In total, the video lasts one minute and thirteen seconds and includes informative text displayed on the screen while inspiring, fast-paced music plays in the background. Its production value is top-notch. The combination of the images clearly display that Lallemand values the work its team has done on Fermacore. And, after talking with the team behind Lallemand’s newest innovation in yeast, it would be hard to argue against them.

The sprinting cheetah is in the video to illustrate how fast FermaCore is. According to Matt Richards, the technical lead working on the yeast product, the new FermaCore product is the fastest Lallemand has ever offered. “If margins are high, producers want to get more product out of the plant,” Richards says. The team worked to produce and test a yeast strain for several years that would provide producers with an option for faster fermentation runs.

According to Angus Ballard, president of the biofuels team at Lallemand, the new FermaCore follows up previous yeast innovations created by the company. But Ballard says Fermacore is not merely an incremental improvement on previous strains. It’s a major step change, he explains, one that will rewrite the next chapter of Lallemand’s place in the ethanol industry and help the industry, in turn, do more with yeast.

In addition to faster kinetics for quicker run times, the product has increased robustness (can withstand higher pressures than previous yeast versions commonly used in the industry), maximizes ethanol yield by helping to express more enzymes and in some cases, eliminates the need to run with glucoamylase, a common addition to ethanol fermentation used by producers for years.

A study published in 2021 from Bioresources and Bioprocessing Journal looked at glucoamylase-expressing yeast strains that could potentially be used in commercial-scale ethanol. According to the study, the cost of exogenous addition of glucoamylase is roughly 4 cents per gallon of ethanol produced, or the equivalent of 8.3 percent of the total processing costs. Ballard says that getting clients to understand that the FermaCore lineup of products eliminates the need (and cost) of adding glucoamylase has required some effort, but its main clients have come around.

“All of our clients want to know who has run it,” he says. “We are lucky to have many customers that have run it because they want to be on the leading edge of the industry.”

Richards and his team are in the process of completing a full lineup of FermaCore products, including an LCI version. The LCI version gets its name from its ability to lower the carbon intensity score at a plant. Because that particular strain can access a greater portion of the corn kernel when compared to previous yeasts. The LCI strain can access more glycerol or liberate more corn oil, Richards explains, which ups the production percentage from the feedstock coming into the plant without upping the amount of feedstock used. That equation, he explains, is a simple way to lower a CI score.

Richards and his team are close to releasing the FermaCore lineup to the open market, but they will also continue to match the unique needs of their industry clients to their lineup of yeast strains. Ballard says the team runs a mobile lab at various ethanol plants so that they can run and test yeast in live mash runs. “That way we can optimize strains for real-world scenarios,” he says.

Overall, the work by Lallemand’s biofuels yeast team is about value creation, Ballard says. FermaCore will help producers make ethanol faster, produce more high-value coproducts and maximize production.

“The rate of innovation regarding yeast is accelerating,” Ballard says. “We are in a competitive market. I would encourage producers to stay aware of innovations that are coming out.”

------------------------------------------------------------------------------------------------------------------

Yeast Innovations for Lignocellulosic Ethanol

Researchers from the Agricultural Research Service at the National Center for Agricultural Utilization Research in Peoria, Illinois, have also looked for, and found, yeast strains that are more hardy, capable, heat tolerant and able to reduce the need for yeast nutritional supplements.

Using a yeast strain found on sweet sorghum, the researchers found what they are calling the “toughest of the tough” strain. The toughness includes heat tolerance, fast growth and an ability to detoxify harmful byproducts like furfural while producing ethanol, ARS says. Z. Lewis Liu, a molecular biologist that previously worked at ARS said the new, “tough” strain also makes its own beta-glucosidase, an enzyme which catalyzes the breakdown of simple sugars like glucose from lignocellulose so they can be fermented into ethanol. This eliminates the need to add beta-glucosidase “and lowers the enzyme cost of cellulosic ethanol production,” he says.

ARS has patented the strain for use in lignocellulosic ethanol production. So far, the strain has outperformed genetically engineered yeast strains already used in industry. Liu said that although the Clavispora yeast doesn't ferment all types of simple sugars available from lignocellulose sources, it still has the potential to reduce the cost of producing ethanol. And, the genetic makeup of the yeast could provide important clues to improving the use of other microbial strains in lignocellulose-based ethanol production systems, ARS explained. “The key,” Liu added, “will be making critical process engineering improvements to the bioreactors now being used, including their ability to stir the cellulosic mix with high loads of fermentable solids.”

------------------------------------------------------------------------------------------------------------------

Author: Luke Geiver

Contact: editor@bbiinternational.com

Advertisement

Advertisement

Related Stories

U.S. fuel ethanol capacity fell slightly in April, while biodiesel and renewable diesel capacity held steady, according to data released by the U.S. EIA on June 30. Feedstock consumption was down when compared to the previous month.

XCF Global Inc. on July 8 provided a production update on its flagship New Rise Reno facility, underscoring that the plant has successfully produced SAF, renewable diesel, and renewable naphtha during its initial ramp-up.

FutureFuel idles biodiesel production amidst regulatory uncertainty, shifts full focus to specialty chemicals growth

FutureFuel Corp. on June 17 announced it will temporarily idle its biodiesel facility upon completion of its remaining contractual obligations, anticipated to occur by the end of June. The company is shifting its focus to specialty chemicals.

The U.S. EPA on June 18 announced 1.75 billion RINs were generated under the RFS in May, down from 2.07 billion that were generated during the same period of last year. Total RIN generation for the first five months of 2025 reached 9.06 billion.

TotalEnergies has announced the company expects its facilities will be able to produce more than half a million tons of SAF a year by 2028 to cover the increase in the European SAF blending mandate, set at 6% for 2030.

Upcoming Events