FEW Online

October 27, 2020

BY Lisa Gibson

“What a year we’ve had,” Emily Skor, CEO of Growth Energy, said in her keynote address at the 2020 International Fuel Ethanol Workshop & Expo. It’s hard to imagine life before COVID-19, she said, adding that the goals she laid out for the industry in February at Growth Energy’s Executive Leadership Conference remain intact. “My vision for this industry hasn’t changed.”

Skor, of course, focused largely on the change the pandemic has brought, saying that while the ethanol industry has never experienced such an unprecedented fall in demand, there is reason for optimism. In managing the crisis, the industry is showing ingenuity, she said. It has faced daunting challenges, but it’s moving faster and more efficiently in surmounting them.

For the first time, FEW was delivered as a virtual event this year, with speakers logging in for live Q&As, sending recorded presentations, and featuring a completely virtual trade show. As the industry has been forced to evolve through COVID-19, FEW has, too. The event was held Sept. 15-17, drawing over 1,000 attendees and 85 exhibitors.

Sept. 15 featured pre-conference seminars: The Low Carbon Fuel Production Workshop and the Biofuels Environmental Health & Safety Forum. Breakout sessions in three tracks followed on Sept. 16 and 17, focusing on production and operations; leadership and financial management; and coproducts and product diversification. FEW was also co-located with the Biodiesel Production Technology Summit and the 2020 American Coalition for Ethanol Conference.

Feedback from speakers and attendees was largely positive, grateful for a safe, virtual platform and for the organized and efficient delivery of the content. The event seemed to be a bright spot for an industry working to get back on its feet after a pandemic.

An Industry Upended

The ethanol industry faced large battles even before the pandemic, Skor said in her FEW keynote. Trade wars, threats to the integrity of the Renewable Fuel Standard and unkept promises, are among them.

“Our losses have been huge,” Skor said of the pandemic downturn. “At one point, as much as half the industry was offline.”

Growth Energy worked with plants to secure small business protection, and is still working with lawmakers to craft relief packages, Skor said.

But the pandemic also highlighted ethanol’s many contributions to industry in its coproducts. “Keep in mind, we are responsible for over 40% of the nation’s industrial carbon dioxide,” Skor said. Ethanol production also provides nearly 40 million metric tons of feed for livestock. “And when there was a shortage of hand sanitizer, the biofuels industry rose to the occasion.

“We showed Washington that ethanol is not only essential, but an unsung hero in the effort to eradicate the virus.

“No other industry is in the same position to revitalize rural America.”

Skor called out President Donald Trump by name, imploring him to stand with U.S. biofuels producers, citing the small refinery exemptions that have dulled demand throughout his presidency. And in June, “Refiners tried to turn their favorite loophole into a time machine,” she said, referring to gap year waivers, which were announced to be denied Sept. 14, two days before Skor’s keynote.

Skor also discussed promising exports and the ongoing work in E15 growth. As the industry and world recovers, she said, Growth Energy is still on task.

Annual Accolades

The FEW general session also featured the presentation of the Award of Excellence and High Octane Award, historical accolades announced each year at the event. This year’s High Octane Award winner is Clean Fuels Development Coalition founder and Executive Director Doug Durante. In addition to producing the Ethanol Across America campaign, The Ethanol Fact Book, The Ethanol Minute radio program and more, he has been involved in almost every federal ethanol policy development over the past 40 years. His full story is highlighted in the August issue of Ethanol Producer Magazine.

“The people I’ve met over 40 years, I’ve developed friendships as close as family—people who follow their convictions and their beliefs,” Durante said in his acceptance speech.

Advertisement

Advertisement

He focused on the benefits of ethanol he has touted for the past 40 years, and the partners he’s worked with. “I don’t believe there is a single, credible, legitimate argument against ethanol. … I’ll debate anyone on that issue.

“I’m honored to have received this award,” he said.

And this year’s Award of Excellence winner is University of Minnesota Department of Bioproducts and Biosystems Engineering research fellow Douglas Tiffany. As a research fellow within the University of Minnesota’s Department of Bioproducts and Biosystems Engineering, he has worked on an array of ethanol-related projects ranging from biomass power, cogeneration and coproduct innovation to feedstocks, grain shipping patterns and new products and markets. His career profile is highlighted in the October issue of Ethanol Producer Magazine.

Tiffany also touted collaborators and graduate students who helped in his research.

“Thank you for this award,” he said, as he concluded his speech.

General Session Discussion

FEW general session panelists dialed in live Sept. 16 for a robust discussion. Chris Bliley, senior vice president of regulatory affairs for Growth Energy; Robert White, vice president of industry relations for the Renewable Fuels Association; and Brian Jennings, CEO of the American Coalition for Ethanol, discussed the biggest industry issues with moderator Tim Portz, program developer for BBI International.

Jennings said the gap waiver denial, announced two days before, is a win, but there’s more work to do. Take a moment to rejoice, he said, but, “We’ve got to get right back to work.”

The denial of the gap year waivers boosted RIN prices slightly, to about 50 cents. It’s a good price for a normal marketplace, Jennings said. “But we’re not in a normal marketplace.”

Jennings also pointed out that the biggest win ethanol has seen was the U.S. 10th Circuit Court of Appeals decision earlier this year. “Having EPA deny 54 of these gap year requests is not a gigantic win. The victory was the court case back in January.” The 10th Circuit found that the U.S. EPA went above its authority in granting certain small refinery exemptions.

EPA still has not applied that 10th Circuit decision nationwide, Jennings added. “So we’ve got an enormous amount of work to do with EPA.”

Discussion also touched on the pandemic and the derecho that whipped through Iowa in August. Bliley said Growth Energy’s members were still recovering and dealing with the effects of that disaster.

Jennings and White agreed, and White said the industry is still in dire times and has to continue to push politically and in the marketplace. As far as the pandemic, the industry is not looking to be back at full steam this year or even next year, White said.

The panel addressed the political climate and the presidential candidates. White said neither is a rubber stamp for ethanol, but it’s interesting ethanol has taken a position in the election as a talking point.

On Production

Three of Ethanol Producer Magazine’s editorial board members followed up the policy panel and kicked off discussion by talking about their experiences with COVID-19. Mick Henderson, general manager of Commonwealth AgriEnergy in Hopkinsville, Kentucky, said the plant implemented temperature checks for employees and learned how to deal with infections. As a small employer, it was a bit nerve-racking, as more than one employee out sick could mean the plant can’t run, he said. “The worry was you could lose your business. Shoot, we didn’t know if those that got infected would lose their life. So, scary time to start.”

Walt Wendland, president and CEO of Ringneck Energy in Onida, South Dakota, said once March and April passed, the plant’s feet were back underneath it and had a semblance of normalcy in the industry. He called COVID a “cliff that we fell off.”

Advertisement

Advertisement

“We made sure that shifts didn’t interact with each other,” Wendland said. “We were cross training maintenance and grain people to be in operations if they needed to be. And we virtually locked the doors on our admin building.” Vendors are being careful and are back on-site with precautions, he added.

“So we’ve returned to normal somewhat. But we feel that we’ve come through this pretty well.”

Dan Sanders, vice president of Front Range Energy in Windsor, Colorado, talked about being a bit closer to urban areas, and early spikes. Initially, of course, the concern was for human health, and, secondarily, the business model. “We were quick to get engaged on new protocols at the plant to deal with new safety and sanitization requirements.” Then Front Range started balancing markets.

Changes to the industry are for the better in handling infectious disease at plants, Henderson said.

“We’ll handle infectious disease much better than we have in the past,” Wendland said. As a new producer, Ringneck felt obligated to continue operating to maintain the relationship with suppliers, he added. “Being new, it was a totally different experience.” Ringneck was able to downsize, but still meet its obligations.

Sanders agreed that the sanitization methods brought about during the pandemic will be long-lasting. “Even for a 13-year-old facility like ours, it was still eye-opening for us.”

As far as production levels, Sanders said plants are back to the “new normal.” It’ll take several years, he said, to even out demand and production. “Through 2021, I think we’ll continue to see a lower supply and demand balance, and we’ll see the industry adjust to that, as we’re seeing right now.”

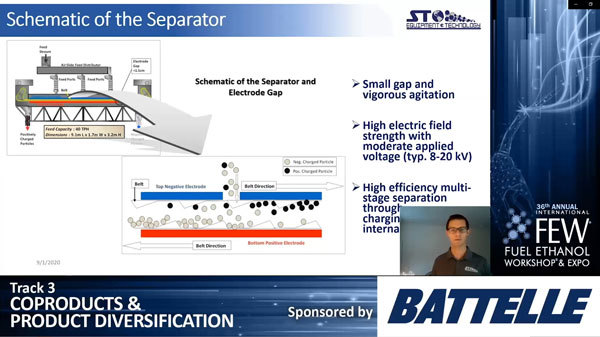

The pandemic also has made plants look at diversifying, he added. It accelerated and broadened coproduct exploration across the industry. “I think it’s smart for the industry to have a more diversified business model.”

Henderson agreed and discussed Commonwealth’s pivot to hand sanitizer production in partnership with local bourbon producers. He said the plant will dabble in other streams, like protein, but other uses for ethanol are at the top of the list.

“I think it’s quite a feat that the industry was able to match demand,” Wendland said of hand sanitizer production. “I think it’s unprecedented for us to respond the way that we did.”

Ringneck also converted to hand sanitizer production during the pandemic for a few months, Wendland said. “I was amazed how fast the goal post moved. At first, they would take anything,” he said, referring to how guidance changed along the way.

There’s room in the industry for diversification chemically, enzymatically or mechanically, Sanders said. COVID-19 undoubtedly sped up the coproduct rush.

“If you were narrowed in on one particular coproduct, now you’re looking at four or five,” he said. “Plants that are able to deploy capital are going to put it to work.”

Author: Lisa Gibson

Editor, Ethanol Producer Magazine

701.738.4920

lgibson@bbiinternational.com

Related Stories

More than 1.76 billion renewable identification numbers (RINs) were generated under the Renewable Fuel Standard in January, down from 1.91 billion generated during the same period of 2024, according to data released by the U.S. EPA on Feb. 20.

The U.S. EPA on Feb. 20 released updated small refinery exemption (SRE) data showing that 13 previously denied SRE petitions for Renewable Fuel Standard compliance years 2021 and 2022 are being reconsidered. No new SRE petitions were filed.

A coalition of biofuel, agriculture, fuel retailer and petroleum trade groups on Feb. 19 sent a letter to U.S. EPA Administrator Lee Zeldin urging the agency to set robust, timely, multiyear RFS RVOs for 2026 and beyond.

OMV Petrom has announced the start of construction for a sustainable aviation fuel (SAF) and renewable diesel (HVO) production unit at the Petrobrazi refinery in Romania. The new facility will have an annual capacity of 250,000 tons.

CVR pauses development of potential SAF projects pending regulatory, tax credit clarity

CVR Energy Inc. released fourth quarter financial results on Feb. 18, reporting reduced renewable diesel production. The company also said it is pausing development of SAF capacity pending clarity on government subsidies.

Upcoming Events