German Biodiesel Quality: 2012 AGQM Survey

May 1, 2013

BY Juergen Fischer

Since its founding in 1999, AGQM, the German Quality Management Association for Biodiesel, has striven for constant improvement in German biodiesel quality. Besides the implementation of an effective and flexible quality management system, one of the most important measures is a frequent biodiesel quality survey of AGQM members.

When AGQM started its activities, biodiesel was sold as B100 at public filling stations. Due to changes in German biofuels policy, today biodiesel is used mainly as a blend component for diesel fuel, and the focus of the quality surveys changed from public filling stations to manufacturers and traders. Despite this, biodiesel still is the most important biofuel in Germany. And even though diesel fuel only contains a 7 percent share of fatty acid methyl esters (FAME), the legal implementation of tighter emission regulations also led to increasing requirements for the fuel, reflected by several modifications of EN 14214, the European biodiesel standard, since its first publication in 2003. This standard is part of the European Fuels Quality Directive; in addition, in Germany biodiesel must meet the German Institute for Standardization (DIN) EN 14214 to qualify for the German biofuels quota. AGQM members participating in the quality survey are usually not subject to regular quality checks by the German customs authorities.

Today, the results of the AGQM quality survey are a unique database for biodiesel quality. It is not only proof for the efficiency of AGQM’s quality management, but also an indicator for quality trends, giving evidence of the significant progress biodiesel quality has made in recent years.

The frequent sampling and analysis of biodiesel is part of AGQM’s quality management program. It is conducted six times a year by an independent surveyor. Samples are taken without advance notice at loading and storage facilities and are analyzed by an independent laboratory that must be accredited for biodiesel analytics to participate in the annual ring test of AGQM and the Mineral Oil and Fuels Standardization Committee within DIN (DIN FAM).

Advertisement

Advertisement

For the analysis, the test methods cited in the current version of EN 14214 are used. The only exception is the total contamination: due to analytical deficits of EN 12662:2008 the 1998 edition was chosen for the determination of this parameter.

The test results are each compared to the requirements of DIN EN 14214 with respect to the seasonal limit values for cold properties. In some cases, the more stringent AGQM limits also apply, however, the tolerance range of the test method is considered in case of borderline results since only single measurements are conducted.

The parameters chosen for the quality survey are the most relevant for the quality of biodiesel. Some of them can be adjusted by process conditions (e.g., CFPP, ester content, metal content), others are related to the feedstock (linolenic acid content, cloud point, density) and indicate the variety of oils and fats used for FAME production in Germany.

On the other hand, parameters that are usually not known as problematic (i.e., cetane number, ash content and carbon residue) are not included in the test program.

The assessment of the quality is made by comparing the test results of each sample with the limit values set by the fuel standard, by legislation and/or by AGQM’s quality management (QM) system. This comparison needs to be adjusted to the current requirements, thus complicating the situation in Germany. While the new version of DIN EN 14214 was published in November 2012, the German legislation still refers to the “old” standard until the legislation is changed accordingly. AGQM, however, decided to implement the new standard immediately into its QM system, making this the basis for the quality check. Furthermore, seasonal requirements have to be taken into account. CFPP and cloud point limits change with the season and have to be adjusted accordingly by the FAME manufacturers.

Advertisement

Advertisement

In total, 132 samples were taken in six campaigns in 2012. The FAMEs were analyzed on a set of 14 parameters: ester content, density (15 degrees Centigrade), sulfur content, water content, total contamination, oxidation stability (110 C), acid number, iodine value, glycerol/glycerides, alkaline content (Na + K), earth alkaline content (Ca + Mg), phosphorus content, linolenic acid content and CFPP. For the November/December campaign, the cloud point was added to the list in order to address the most recent changes of EN 14214. Regarding the precision of the test methods, the so-called limits of rejection are considered for distinguishing between off-spec and on-spec samples.

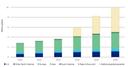

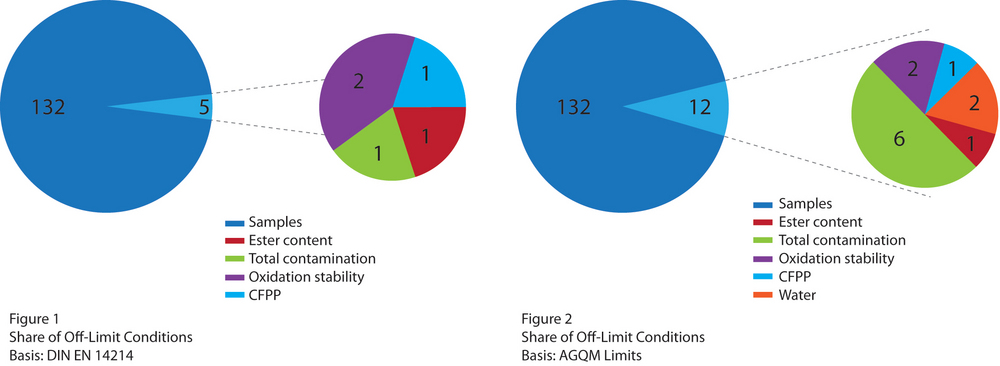

The overall result of the survey is excellent. Only five limit violations are found in four samples out of 132, compared to the requirements of DIN EN 14214 (Figure 1). In comparison to the more stringent limit AGQM has set for total contamination and water content, a few more critical samples were identified (Figure 2). Oxidation stability (note the “2” in Figure 1), CFPP, total contamination and ester content are critical parameters linked to the production process. In all cases, corrective measures were taken immediately to improve the biodiesel quality. It’s important to note that, in this case, more than 96 percent of all tested samples fulfilled all requirements. Only one sample showed a deviation in more than one parameter.

In summary, AGQM’s quality management system includes a frequent check of the quality of its members as one of its most important aspects. This measure serves, on the one hand, as a control instrument and, on the other, as support for the internal quality control of the members. At the same time, the data collected during AGQM’s 13-year history are, worldwide, a unique database on the development of biodiesel quality, reflecting also constant improvement and optimization of production processes.

In 2012, more than 98 percent of the samples fulfilled all requirements of DIN EN 14214. Only five out of approximately 1,900 single results deviated from the standard requirement. In all cases, the root cause of the issue could be identified and corrective measures were initiated to solve the problem.The 2012 biodiesel quality survey impressively demonstrates again the use of such a custom-made quality management system.

Author: Juergen Fischer

Chairman of the Board, AGQM

juergen.fischer@adm.com

Related Stories

Clean Fuels Alliance America on June 10 announced the launch of the newly redesigned BQ-9000 website, delivering a streamlined and user-friendly experience that better showcases the value of biodiesel quality assurance.

Global Biofuels Alliance launches at G20 Summit

President Joe Biden on Sept. 9 joined leaders of India, Argentina, Brazil, Italy, Mauritius and the United Arab Emirates to launch the Global Biofuels Alliance. The launch took place on the sidelines of the G20 Summit in New Delhi.

Neste is disputing a report filed with the USDA that suggests the company may have received fraudulent used cooking oil (UCO) volumes at its renewable products refinery in Singapore, specifically virgin palm oil from Indonesia.

Members of the European Parliament (MEPs) on Sept. 13 approved a new law that ramps up requirements for sustainable aviation fuel (SAF) within the European Union but sets limits on what types of feedstocks that fuel can be made from.

Clean Fuels outlook predicts growing supplies of used cooking oil

Global used cooking oil (UCO) supplies are anticipated to rise from 3.7 billion gallons in 2022 to between 5 billion and 10 billion gallons by 2030, according to a report released by Clean Fuels Alliance America on Sept. 13.

Upcoming Events