Green Plains reports progress with improvement initiatives

November 5, 2020

BY Erin Krueger

Green Plains Inc. reported progress with its Project 24 initiative and projects to increase production of high-protein feed products and high-quality alcohol during its third quarter earnings call, held Nov. 5.

“Our third quarter results improved significantly over the prior year with a consolidated crush margin of 8 cents per gallon and EBITDA of $8.8 million. Margins this quarter included nearly 6 cents per gallon of negative absorption due to lower utilization rates resulting from Project 24 upgrades, regional market conditions, and scheduled biannual plant maintenance,” said Todd Becker, president and CEO of Green Plains in a Nov. 4 statement. “We were pleased with the performance of our operating plants which earned approximately 14 cents per gallon consolidated crush margin during the quarter, with the expectation that these results would improve further as we continue to progress on our Project 24 initiative. Our results were also impacted by the deferment of scheduled third quarter high grade alcohol sales deliveries from our York location into the next two quarters, as a number of customers elected to wait until our upgrade to USP grade alcohol is completed in the fourth quarter. We anticipate a stronger fourth quarter based on current market conditions, expected higher operating rates, less negative absorption and the completion of the upgrade at York.”

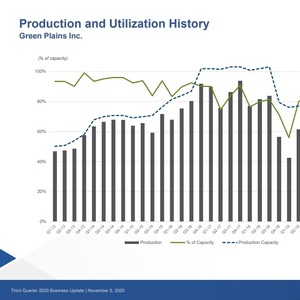

During the earnings call, Becker reported that Green Plains produced 189 million gallons of ethanol during the third quarter, which equates to a 67 percent run rate at its facilities. The fourth quarter is looking to be better than the previous quarter based on current market conditions, higher operating rates, less negative absorption and the completion of upgrades being completed at its York, Nebraska, plant.

Advertisement

The York plant is expected to be producing USP grade ethanol at full capacity by late December. Green Plains plans to implement additional upgrades at the York plant by adding technology supplied by Fluid Quip Process Technologies to produce grain neutral spirits (GNS), a high value alcohol product.

Becker also discussed upgrades being made by the company to produce high-protein products. He said Green Plains broke ground on the installation of Fluid Quip’s high protein system at its Wood River, Nebraska, plant in late September. The facility will be Green Plains’ second plant to add the technology. Startup is currently expected during the second quarter of next year. The company has also announced plans to install the high protein technology at its plant in Obion, Tennessee. Once all three projects are operational, Green Plains will have the capacity to produce 200,000 tons of high protein product annually, Becker said.

Advertisement

Regarding Green Plains’ Project 24 initiative, which aims to reduce the company’s per-gallon operating expense to 24 cents, Becker said upgrades are continuing at the company’s Mount Vernon, Indiana, facility, and are expected to be complete in the first quarter of next year. The company is soon expecting to receive the necessary permits to begin Project 24 improvements at its Madison, Illinois, facility.

Green Plains reported a net loss attributable to the company of $34.5 million, or a loss of $1 per diluted share, inclusive of a non-cash income charge of $13.8 million, for the third quarter, compared to a net loss of $39 million, or a loss of $1.06 per diluted share, for the same period of 2019. Revenues were $424.1 million for the third quarter, compared to $632.4 million.

Related Stories

U.S. fuel ethanol capacity fell slightly in April, while biodiesel and renewable diesel capacity held steady, according to data released by the U.S. EIA on June 30. Feedstock consumption was down when compared to the previous month.

XCF Global Inc. on July 8 provided a production update on its flagship New Rise Reno facility, underscoring that the plant has successfully produced SAF, renewable diesel, and renewable naphtha during its initial ramp-up.

The USDA’s Risk Management Agency is implementing multiple changes to the Camelina pilot insurance program for the 2026 and succeeding crop years. The changes will expand coverage options and provide greater flexibility for producers.

EcoCeres Inc. has signed a multi-year agreement to supply British Airways with sustainable aviation fuel (SAF). The fuel will be produced from 100% waste-based biomass feedstock, such as used cooking oil (UCO).

SAF Magazine and the Commercial Aviation Alternative Fuels Initiative announced the preliminary agenda for the North American SAF Conference and Expo, being held Sept. 22-24 at the Minneapolis Convention Center in Minneapolis, Minnesota.

Upcoming Events